August 2024

Digital Issue

IMTS 2024: Inspiring the Extraordinary. Welcome to the largest manufacturing technology show and marketplace in the Western Hemisphere. Powered by AMT - The Association For Manufacturing Technology, IMTS takes place every two years, bringing together creators, builders, sellers, and drivers of manufacturing technology to connect and be inspired. Attendees will discover advanced manufacturing solutions in areas such as CNC machining, automation, robotics, additive, software, inspection, and transformative digital technologies that drive the future of manufacturing forward.

Subscribe View Digital IssueSelect the right abrasive product for your application and follow best practices to achieve the results you want.

Understanding what type of robotic or cobotic system best suits your needs, and the core considerations for overall automation management, make their introduction an even smoother and more helpful process.

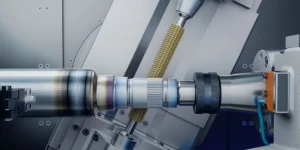

A specialized or premium boring head can deliver a return on investment in a single production run.

The latest laser and fabrication technology will be showcased at IMTS 2024.

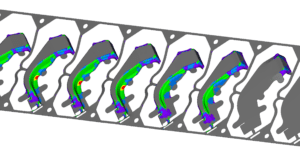

Optimizing a traditionally manufactured application for additive manufacturing requires a complex set of steps.

Heck Industries began like many other companies: inside a two-car garage over 50 years ago.

Now in its 50th year, ANCA CNC Machines is celebrating several highpoints in its storied history, while continuing to offer best-in-class solutions for tool grinding production, start to finish.

Digital transformation will be featured at the software pavillon at IMTS 2024 in Chicago.

A variety of metal removal machines will be displayed in Chicago at IMTS.

See the latest gear technology at IMTS 2024.

The latest automation technology will be highlighted at IMTS 2024 in Chicago.

IMTS 2024 will feature abrasive machining, sawing and finishing.

Automation technologies are omnipresent in the metalworking industry, and at IMTS 2024.

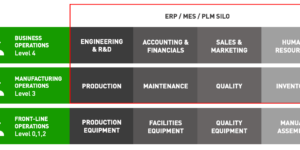

There are two key items to highlight as manufacturers adopt solutions to digitize their operations: context is king, and insights are greater than just mere data.

Select the right abrasive product for your application and follow best practices to achieve the results you want.

Understanding what type of robotic or cobotic system best suits your needs, and the core considerations for overall automation management, make their introduction an even smoother and more helpful process.

A safety first culture shields your shop from costly fines, productivity setbacks, and potential legal troubles. Safety isn’t just a program; it’s a way to show your employees that you care.

Now in its 50th year, ANCA CNC Machines is celebrating several highpoints in its storied history, while continuing to offer best-in-class solutions for tool grinding production, start to finish.

A specialized or premium boring head can deliver a return on investment in a single production run.

The lateset technology in tooling and workholding will be on display at IMTS 2024.

From CMM’s to automation systems, quality assurance will be on display at IMTS in Chicago.