Products

Manufacturing Product News

Looking for information on the latest products in the industrial world? Look no further! Check out our product overviews below.

The Latest Updates in Technology

For more than a decade, we at Fabricating & Metalworking Online have carried stories on the latest machines and equipment to hit the market. Take a look at our latest updates, go back in our archives to see what we’ve written about in the past.

Filter by Process Zone:

Quality Mass Production with Metal Binder Jetting IS Possible

Hexagon’s Simufact Additive powerful and scalable process simulation environment for first-time-right optimization of metal binder jetting (MBJ) predicts and automatically corrects for final distortion and residual stresses of 3D-printed parts.

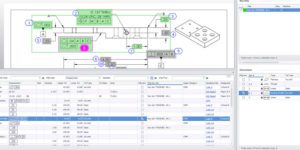

Software Add-On Saves Time and Improves Consistency

DP Technology’s Esprit Additive for Powder Bed is compatible with any file supported by SolidWorks. The add-on application streamlines production by eliminating the need to repeatedly define manufacturing information.

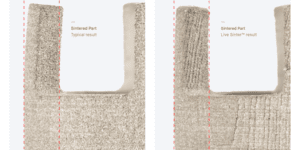

Simulation Software Takes Guesswork Out of 3D Metal Printing

Live Sinter enables inexperienced 3D-printer operators to consistently produce accurate parts using Desktop Metal’s Shop System and Production System machines. The software automatically overcorrects for the shrinkage and distortion inherent in sintering.

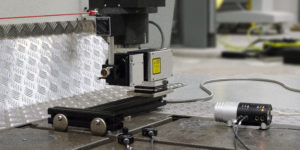

Multiaxis Calibrator With Unlimited Measurement Range

Long-range measurement functionality in Carto 4.2 operating software enables Renishaw’s XM-60 multiaxis calibrator to capture and analyze data from a linear axis regardless of how long it is. The program also facilitates Heidenhain linear compensation.

Versatile and Virtually Seamless Dual-Measurement System

All Mitutoyo America FormTracer Avant models can be retrofitted with detectors that convert a contour measuring unit or surface roughness tester to a high-precision system that measures both attributes without closing down the software or switching off the controller.

Take Metals Analysis on the Road

Hitachi High-Tech Analytical Science adds SpArcfire operating software to its mobile optical emission spectrometer (OES) analyzer product line. The intuitive interface makes metals analysis easy, eliminating the need for extensive training or highly experienced operators.

Software Offers More Opportunities to Automate Quality Assurance

In addition to eliminating paperwork, High QA’s Inspection Manager (IM) Version 5.1 further streamlines collaboration and compliance on the shop floor. Upgrades speed the process of collecting and managing data, from planning through reporting, by five to 10 times.

Easy-to-Use Arm-Mounted Laser Scanner

Exact Metrology offers the RS6 laser scanner, which collects data at full speed regardless of part geometry, for use with the Absolute Arm cobot. The scanner is easily removed from the arm while probing and can be remounted in seconds with no time-wasting recalibration.

Fully Automated Tool Presetting Slashes Machining Setup Times

For shops that use shrink fit holders, duplicate assemblies or multispindle machines, Haimer’s VIO linear toolshrink provides fully automated presetting with incorporated shrink fit technology for precise length adjustment on the μm scale that can reduce setup times up to 70%.

Indexable Insert Drill Balances Performance and Cost-Effectiveness

The balanced four-insert design of Walter’s D4120 helps deliver process reliability, enhanced surface finishes, and hole tolerances. Balancing cutting forces between the center and peripheral insert ensures hole-diameter precision.

Increase Productivity When Machining Heat-Resistant Super Alloys

Unpredictable tool life and slow rough-machining speeds hinder heat-resistant super alloy (HRSA) component productivity. New Secomax CW100 silicon carbide whisker-reinforced ceramic insert formats and geometries successfully tackle materials such as Inconel 718 and Hastelloy.

Inserts Support Both Unmanned Production and Custom Components

Sandvik Coromant uses a second-generation chemical vapor deposition (CVD) alumina coating to produce two turning grades – GC4415 and GC4425 – that withstand the extreme temperatures of P25 cutting zones during continuous operations.