Products

Manufacturing Product News

Looking for information on the latest products in the industrial world? Look no further! Check out our product overviews below.

The Latest Updates in Technology

For more than a decade, we at Fabricating & Metalworking Online have carried stories on the latest machines and equipment to hit the market. Take a look at our latest updates, go back in our archives to see what we’ve written about in the past.

Filter by Process Zone:

Updated Software Simulates and Automatically Corrects Bending Sequence

Available in two versions with varying levels of functionality, transfluid’s Windows-based t project software links geometry and material data to achieve precise bending results.

End Formers for Aerospace, Tank, and HVAC Components

Two models – the 2.5 and 4.0 – from Kaast Machine Tools ensure consistently accurate strength-promoting beads in materials up to 0.15-inch (4mm) thick. Available with mechanically (ZSM) or hydraulically (ZSH) driven upper rolls.

Track and Control Stamping Operations in Real Time From Wherever You Are

IRMCO Advanced Metalforming Lubricant Technologies’ iNSIGHT enables metal stampers to track the rate of chemical consumption by part and process and compare the data to tool life to pinpoint the actual cost per part for each process in a facility.

Two Electric Upcut Tube Saws

Two standard models – the eRB80 TS and eRB150 TS – electric upcut tube saws from Innovative Engineered Solutions (iES) cut diameters up to 3.5 inches (90mm) and 5.9 inches (150mm), respectively.

Fully Integrated System Automates Pipe Cutting From Start to Finish

HGG Profiling Equipment’s ProCutter900 RB increases throughput by continuously feeding, cutting and profiling, and moving pipe out. The small-footprint machine’s accuracy dramatically reduces post-cutting grinding, fitting and welding time.

Automated Centerless Tube Grinder

An automated version of Glebar’s TF-9BHD infeed/thrufeed centerless grinder, the TF-9D features the widest work wheel on the market. Customizable interface designed for automation and 8-5/8-inch-wide work wheel combine to increase throughput.

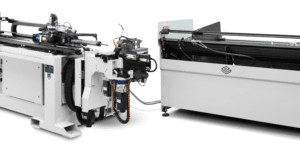

Autonomous Tube/Wire Bender Enables Lights-Out Production

Featuring a compact layout, integrated loading/unloading capability, and easy-to-use programming software, BLM Group’s Smart Bender enables an operator to go from design to part in one click and walk away.

High-Force Actuators Support Robotic Sheet-Metal Welding

Tolomatic’s CSW and CSWX Compact ServoWeld welding gun actuators for robotic spot welding integrate a 3,507-lbf and 4,047-lbf, respectively, actuator into a hollow-core servo motor for faster resistant spot-weld cycles.

Cobot Simplifies and Improves Large-Pipe Welding

Requiring just 4 square feet of shop floor space, Novarc Technologies’ spool welding robot (SWR) enables inexperienced welders working on pipe spools up to 30 feet long to monitor and adjust parameters to pipe variations in real time.

Portable and Easily Adaptable Welding-Automation Solution

Lincoln Electric’s Fab-Pak Cobot Cart enables small- and medium-sized fabricators to justify investing in automation by providing a mobile, easy-to-program, and safe robotic welding solution.

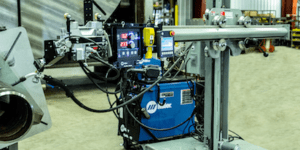

Space-Saving Automated Welding Package for Pipe Fabricators

Koike Aronson Ransome’s pipe-welding package incorporates the Cricket-I manipulator. Providing 20-IPM lift speed and 150-pound load capacity, the manipulator ensures productivity increases without sacrificing floor space.

6-Axis Welding Cobots Provide Maximum Flexibility

Fanuc adds 15- and 33-pound-payload welding cobots to the ARC Mate product line. The arc welding cobots’ easy-to-program interface supports both simple and complex applications using advanced features.