Products

Manufacturing Product News

Looking for information on the latest products in the industrial world? Look no further! Check out our product overviews below.

The Latest Updates in Technology

For more than a decade, we at Fabricating & Metalworking Online have carried stories on the latest machines and equipment to hit the market. Take a look at our latest updates, go back in our archives to see what we’ve written about in the past.

Filter by Process Zone:

Three Robot-Ready 5-Axis Vises

Kurt Workholding replaces HP-model vises with Precision Force (PF) MaxLock vises featuring a patented locking mechanism that holds parts securely, keeps them square with excellent repeatability, and are affordable.

Redesigned Insert Clamp Improves Rigidity

The toolholder for Horn USA’s Supermini grooving and boring tools applies a tensioning wedge to the insert’s face rather than circumference, increasing rigidity and repeatability.

Choose the Material that Will Provide the Strongest Grip for Your Workpiece

Dillon Manufacturing can manufacture soft or hard and full-grip special top jaws in a wide range of materials and configurations to ensure chucks provide maximum grip for an application.

Manual Swing Clamps Provide the Best of Both Worlds

Destaco combined the best features of pneumatic swing clamps and straight line action clamps to create a low-cost workholding option for fixture builders. The manually actuated swing clamps eliminate the need for air.

Small-Footprint Vertical Machining Centers (VMCs) for Small Part Production

An economical option for small shops that need a second machine or additional spindle, all three models of Palmgren’s vertical machining centers (VMCs) have a 10-tool magazine with automatic changer and user-friendly portable handwheel.

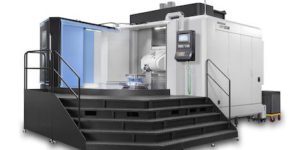

VERY Heavy-Duty Horizontal Machining Center (HMC)

Ideal for the demanding aircraft, automobile, power generator, mold-and-die, and semiconductor industries, Niigata’s 5-axis HN80E-5X horizontal machining center (HMC) produces 1.65-ton parts almost 50 inches in diameter and 40 inches high.

5-Axis Vertical Machining Center (VMC) Provides Large Work Envelope Relative to Footprint

Engineered for tight-tolerance work for the mold and die, aerospace, and energy industries, Mitsui Seiki’s compact Vertex 100 provides a large workpiece capacity so operators can process a wider range of parts.

Smaller-Footprint, Easier-to-Use Vertical Machining Center (VMC)

Mazak’s VC-Ez 20 is the first of three vertical machining centers (VMCs) that offer much the same functionality and performance as previous models, but in a more compact and more affordable package.

High-Speed, Large-Capacity 5-Axis Vertical Machining Center (VMC)

Thanks to a 75% increase in work envelope and high traverse rates, Matsuura USA’s MAM72-52V processes larger-diameter and heavier workpieces than its predecessor. Integrated tower pallet enables lights-out production.

How to Easily Automate Vertical Machining Center (VMC) Tending

With Quick and Simple Startup of Robotization (QSSR), Fanuc simplifies the process of connecting and programming a Fanuc robot or cobot. The all-in-one package enables operators to program the robot using the machine’s CNC.

Machine and Turn 2-Ton Workpieces in A Single Setup

Doosan’s DHF 8000ST is a single-table version of the company’s DHF 8000 5-axis horizontal machining center (HMC) that incorporates a turning function so manufacturers can save time by moving from roughing to finishing with one setup.

Twin Spindles Machine Large Components With Great Precision

Available in 4- and 5-axis versions, Chiron’s dual-spindle DZ 22 has a fast spindle for machining aluminum and aluminum alloy workpieces and a strong spindle for machining hard materials and large tools.