Products

Manufacturing Product News

Looking for information on the latest products in the industrial world? Look no further! Check out our product overviews below.

The Latest Updates in Technology

For more than a decade, we at Fabricating & Metalworking Online have carried stories on the latest machines and equipment to hit the market. Take a look at our latest updates, go back in our archives to see what we’ve written about in the past.

Filter by Process Zone:

World’s Most Powerful Vacuum Gripper Cost-Effectively Lifts Heavy Loads

Capable of lifting 44 pounds (20 kg), OnRobot’s electrically powered VGP20 vacuum gripper performs the same heavy-duty tasks as a pneumatic gripper for a fraction of the cost and complexity. Compatible with all major robot brands.

An Electromagnetic Chuck for Virtually Any Application

An increasingly popular alternative to standard mechanical workholders, magnetic chucks lower setup time and provide access to all sides of a workpiece. They’re particularly helpful for holding circular workpieces during hard turning and free state grinding.

Jaws Firmly Grip but Don’t Damage Fragile Components

Designed for MicroCentric, Northfield, and other precision workholding manufacturers’ air chucks, Dillon Manufacturing’s full-grip pin location jaws hold fragile components securely in place without marring their surface.

Control System Upgrade Makes Faster Tube Manipulation A ‘Breeze’

Unison’s upgraded Unibend software creates speed improvements, reduced pause time between process movements, and other time-saving features for its Breeze tube bending machines. Customers bending significant quantities of tube – such as those in the automotive sector – stand to benefit the most.

Cleanroom-Ready Gripper for Demanding Applications

OnRobot’s IP67-certified, collaborative 2FG7 parallel gripper is the latest addition to OnRobot’s range of no-fuss, all-electric gripper products. Deployed within minutes, it’s designed to handle demanding payloads, even where space is tight.

Machine Cuts Through Titanium Like Butter

That’s what General Electric Global Research said about Blue Arc, an EDM-like process it developed to rough aircraft engine components out of huge blocks of difficult-to-cut alloys. Mitsui Seiki has sold the first commercially available CNC machine that incorporates the technology.

Economical Automation Solution for High-Mix, Medium-Volume Jobs

With the updated JobShop Cell PRO, Methods Machine Tools offers manufacturers a multiaxis simultaneous vertical machining center with multiple end-of-arm and infeed/outfeed options. The efficiency-enhancing cell can be immediately shipped.

5-Axis Machines Cut Diverse and Complex Shapes In One Setup

Automation options for DVF Series simultaneous 5-axis vertical machining centers from Doosan Machine Tools America save time and money by enabling shops to run production parts overnight and quickly switch over to prototype parts.

Safely Inspect Small-Diameter Tube and Pipe Welds in Real Time

Suitable for outside diameters of 0.2 to 8 inches (5 to 200 mm) and maximum bead widths of 0.4-inch (10 mm), Xiris Automation’s WI-2200 weld inspection system incorporates a Class 2 laser that won’t injure employees.

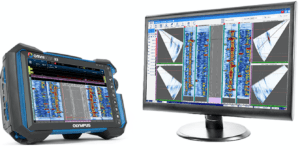

PC Software Maximizes Weld Flaw Detector’s Capabilities

Flexible and customizable WeldSight software for Olympus’ OmniScan X3 phased array flaw detector saves time and effort. In addition to advanced screening capabilities, the program enables inspectors to quickly optimize multiple tools for analyzing complex geometries.

Monitor Ensures Oxide-Free Titanium Welds in Automated Applications

Huntingdon Fusion Techniques’ updated PurgEye 500 Desk weld purge monitor is equipped with PurgeNet. The networking device connects to smart accessories including the drive system for automatic welders and orbital welders and a light accessory for visual warning.

Compact Cladding Cell Accommodates Diameters Up To 3.25 Feet

Fronius has taken a simple, compact solution for cladding applications on smaller parts and developed it for larger tasks. The all-in-one cell’s controls support two processes: TIG hot wire and a two-wire SpeedClad Twin process that’s three times faster.