Column

Filter by Process Zone:

The Higher Power Behind Power Sources

Many welders are still not aware that it is now possible to combine and capture all the information associated with their welding operation into one simple interface – their power source. This is the most advanced way to approach data acquisition and production monitoring in the welding industry.

No Chips, This Time

As technologies merge and metal fabrication applications grow more complex, CNC is now becoming a powerful alternative solution to PLCs for builders and users of metal forming and “non-traditional” machine tools, such as EDM, abrasive waterjet and others.

Competing in the World of Big Data

The manufacturing sector has come far in its use of analytic data, but not far enough. Ben Kerschberg of the BK Advisory Group explains why manufacturers who do not embrace a complete vision of using this tool will soon find themselves at a significant competitive disadvantage.

When Welding Moves Outside

Take a look at how digital, software-based, networked machines deliver repeatable results under the most unpredictable conditions are making a competitive difference as more welding of higher-grade materials moves to rugged outdoor environments for extended periods of time.

How to Control the Warping of Parts in Thin Sheet Metal

Weld shrinkage cannot be prevented, but it can be controlled. Here are several steps that will prevent parts from being distorted after welding.

True CNC Tool Management: From Set-Up to Final Finish Pass

There once was a time when a tool was needed to redo a section, that it might have taken several minutes to recall the program, find the right tool number, identify the proper path and redirect the operation. Not anymore. Randy Pearson of Siemens Industry explains why.

Why You Need Gas and Equipment Savvy for a Second-Hand Laser

A factory-reconditioned or second-hand laser is a good way to increase shop productivity at a fraction of the cost of a new machine. Incorporating these principles and pointers into the purchase and installation of a second-hand laser should assist you in achieving first-class efficiency and operation.

Knowing When to Automate Your Laser Operation

While it is quite common to evaluate the purchase of a laser cutting machine in great detail, much less consideration is given to what is required to keep that system in continuous operation. Lukas Baechler of TRUMPF explains how, when automation is done properly and the right equipment is used, all of the components required for an individual system will run with a perfect flow of material, better quality, and lower costs per part.

Stop Business Crises Before They Create Havoc

Let’s all give thanks for the entreprenuerial spirit that drives our industry. And with that thanks, just in case, here are some nuggets that might save the corporate neck of some entrepreneurs.

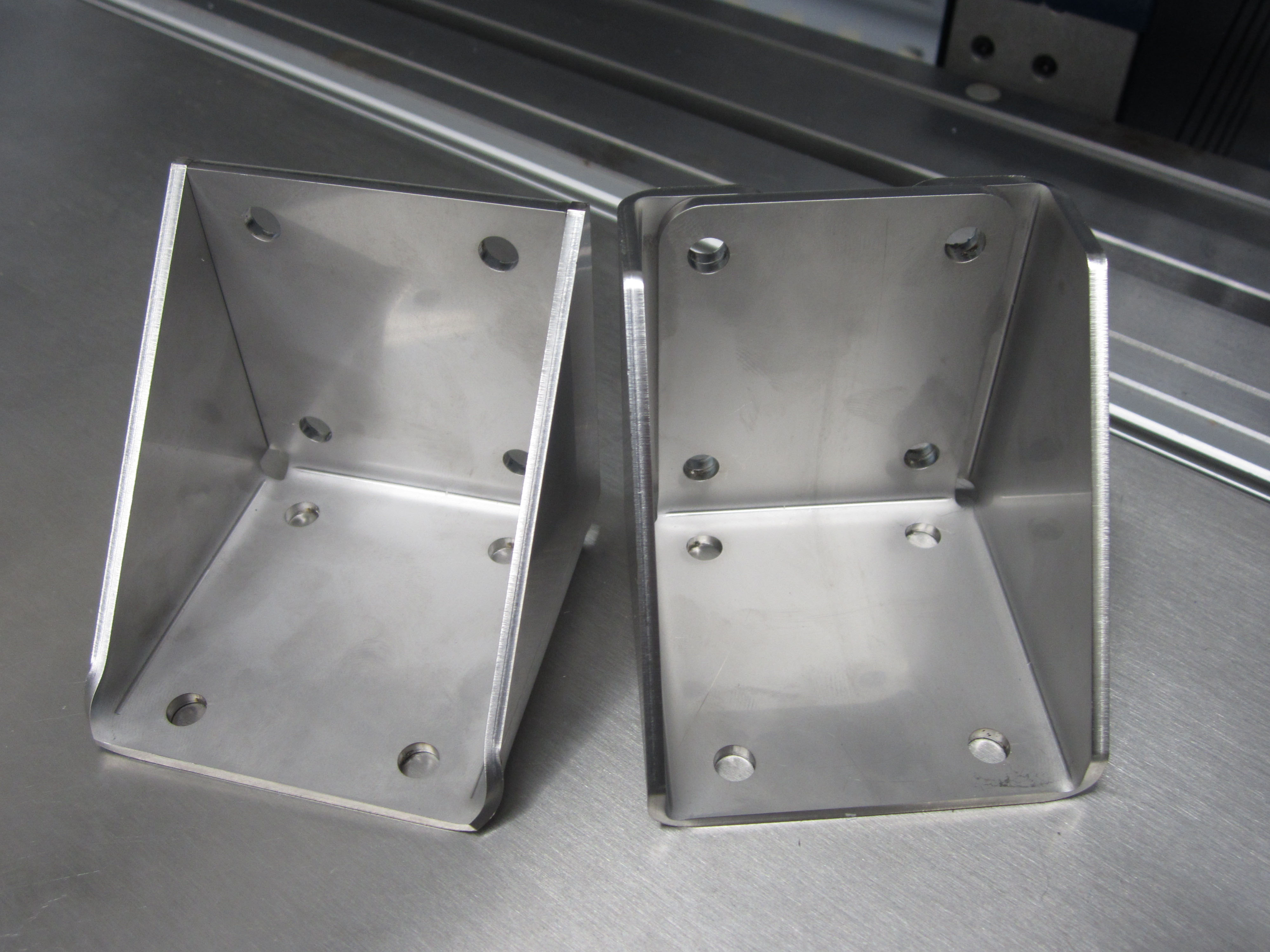

Rethinking Parts In Sheet Metal Design: The Angle Bracket

Revisiting the steps used to make a common bracket can eliminate the need for welding, make the part even easier to produce, and demonstrate how the smallest improvements in part design can reap major benefits in time and money.

Is Your Workplace Ripe for a Serious Injury?

The absence of injuries does not denote the presence of safety. In fact, a series of near misses indicates a problem in your safety management. Here are some important safety factors that identify whether your shop is at heightened risk of a serious injury or fatality.

Push or Drag Angle with GMAW to Reduce Porosity – The Answer Is: It Depends

Lesson Learned: This analysis shows how one must be careful of getting locked into welding a certain way only because that’s the way it has always been done.