Column

Filter by Process Zone:

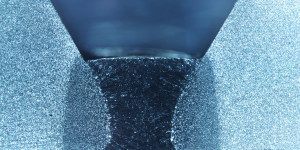

Determining Actual Grinding Productivity & Cost

By evaluating and tracking abrasive performance, combined with taking the time to select the best abrasive for a particular application, job shops and production operations can identify opportunities to significantly decrease grinding costs and increase productivity.

New Arc Process for More Efficient Welding

A new algorithm uses the high processing power, large memory, extremely fast system bus and highly dynamic wire feed speed of the latest MIG/MAG power source platform to ensure an extremely stable arc with minimal spatter.

How Engine-Driven Welder/Generators Save Space and Fuel

A diesel engine-driven welder/generator with dual-operator capabilities is one fuel-efficient machine that provides a full range of jobs and options for multiple users on the service truck or the jobsite — all without sacrificing arc quality or productivity.

Beware of Bad Bargains

Watch out for artificially low prices on aftermarket plasma torch consumable parts. Before you buy, it is important to be aware of a few of the poor performance issues and risk of torch damage that your shop will experience if you purchase imitation consumables.

Hybrid Machine, Standard CNC

As the era of additive/subtractive machine tools emerges, Randy Pearson of Siemens Industry explains how today’s controls are well suited to handle the challenges.

Understanding the Basics of Low-Hydrogen Stick Electrodes

Knowing the basics about E7018 low-hydrogen stick electrodes can be helpful in understanding how to maximize their operation, their performance and the welds they can produce.

When It Comes To Safety: Fix the Problem, Not the Blame

As business increasingly uses safety performance as a criterion to judge the worthiness of a supplier, avoiding these common mistakes is crucial to remaining competitive.

Approaching Industry 4.0

A revolution is about to happen in the sheet metal business that will change the way fabricators compete – whether they are prepared for it or not. It’s time to research the strategic impact of automation in your shop, along with the related personnel, training and suppliers that you will need to make it meet your goals. This is going to determine your competitive position in the global market. Are you ready?

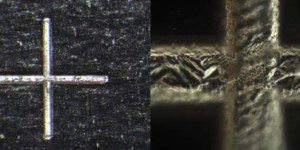

Micromachining of Metals Cheaper, Faster with New Laser Technology

Advances in single mode fiber laser marking technology with superior beam quality can now replace traditional EDM or other micromachining equipment.

Next Frontiers for Lean

Lean production techniques have been revolutionizing operations for 50 years. Guest columnists Ewan Duncan and Ron Ritter of consulting firm McKinsey & Company think through how coming advances in technology, psychology, and analytics may make the next 50 even more exciting.

Your CNC: OEE On Steriods

Your CNC has a learning curve, and you might be surprised by all it can know and tell you now, to help you run a more efficient shop floor or production department.

Robotic MIG Gun Options that Improve Quality and Reduce Downtime

The wire brake and air blast can be used together or separately to help improve quality and performance in robotic MIG gun applications, leading to cost savings for welding operations.