Column

Filter by Process Zone:

Dealing with Confidentiality Agreements

Because customers, suppliers and employees change more frequently than in the past, the use of Confidentiality Agreements is growing as manufacturers protect their intellectual property in materials development, automation, fabrication and machining processes, and other trade secrets that are not patented. Here are some points to consider when asking for and receiving protection under Confidentiality Agreements.

What Stops Salespeople From Moving Forward?

In sales, there’s nothing as valuable as gathering and putting together pieces of intel, making the connections, and discovering the patterns. While a positive mental attitude is always good, it takes something more to propel salespeople forward. It takes the right actions.

Leveling the Field in Heavy Fabrication

Flattening a warped steel part that is nearly two inches thick is extremely difficult, even with a flattening press and a lot of experience. But for a heavy fabricator that uses one of the largest parts levelers in North America, it’s just a matter of setting a few parameters in the control and feeding the problem part into the machine, which hits it right on the first pass.

How to Meet Critical Deadlines and Improve Safety in the Field

Faced with a growing shortage of skilled labor and demands to complete jobs faster than ever before, contractors must do something to maximize their productivity. What is the answer?

A Little TLC Means a Lot to Press Brake Tooling

Press brake tools are the only parts of the machine that ever touch the finished parts being formed. The best precision CNC press brake cannot produce good products with poor tooling, and bad tooling makes all the good hardware in the process – including the machine operator – useless.

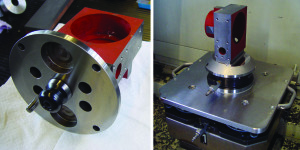

Beat the Competition on a Budget with this Entry-Level ‘Automation’

The way we machine parts has changed significantly over the years. Now it’s time to change how we think about workholding too.

Is Source Capture Enough? Looking at Ambient Options

You already have source capture systems in place for your welding operations. Do you also need an ambient air quality system? If your air isn’t as clean as it should be, you might want to consider it.

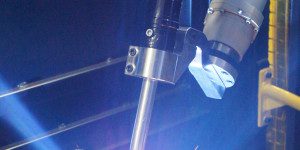

Bionics and the Future of Flight

Of all the advances taking place in the aerospace industry, none holds more promise than additive manufacturing, a disruptive mother lode of quicker throughput, more cost-effective components, and unimaginable freedom of design in lightweight construction and function integration.

Ways to Get the Most Out of Your MIG Gun Consumables

Here are a few of the best practices that every welding operator should know when it comes to choosing and maintaining nozzles, contact tips, retaining heads and gas diffusers, and cable.

Making the Most of Your Investment for the Long Term

The investment in your new machine doesn’t stop with its installation. The better we treat the machine, the better the machine will treat us, hopefully for decades to come. Here are some considerations that can help prevent downtime and extend the life of your fabricating equipment.

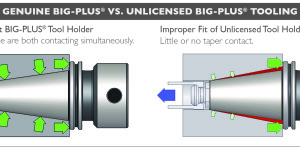

Is BIG-PLUS An International Standard?

Buyer Beware: This system has not been standardized by any governing body. If you purchase cheap dual contact tooling after being told by a supplier that it will work just as good as the original for half the price, you risk unsatisfactory performance and/or damage to very expensive spindles. Here’s why.