Column

Filter by Process Zone:

Cutting Corners: The Idea Behind Power Ramping

Although power ramping has proven to be highly beneficial, it is often underutilized on the shop floor because fabricators either do not understand its benefits or they just don’t know how to use it. By simply applying the given values and principles presented here, they will see a visible improvement in corner and radii cut quality.

Automating the Factory Environment

Imagine whole-plant environmental automation data feeding smart control systems in your shop that respond in real time and learn over time to anticipate and respond to the needs of the humans in your shop – perhaps even better than the humans can. It’s time to start thinking about your environmental systems in a whole new way – or maybe stop thinking about them at all. After all, they’ll soon be able to take care of themselves.

A More Productive Alternative to Helical Interpolation for High Volume Holemaking

The limitations of using milling tools to prepare holes for finishing become apparent as hole depth and volume increase. Enter the relatively simple and affordable twin cutter, which can solve this and virtually any other holemaking problem.

Benefits of Financing Remain with Lease Accounting Changes

The new lease accounting standard by the Financial Accounting Standards Board will not impact shops wanting to acquire advanced manufacturing equipment to grow their business. Here are some of the changes on operating leases for capital equipment that your shop should be aware of and prepare for.

The World’s Best Business Tool

Many of the problems businesses experience aren’t caused by a failure to act, but a failure to think.

Buyer Awareness

This Product Showcase & Buyers Guide is designed to help you learn more about some of the new equipment and services that can give you a competitive advantage in your operations.

Automotive Industry Reaches Cruising Altitude

The automotive industry has reached an inflection point and the entire manufacturing value chain will need to change the way it traditionally does business to remain profitable and be prepared for a future downturn. Here’s why.

Waste Not, Want Not

Planned downtime for preventive maintenance in the welding operation is not time wasted. Here are some crucial maintenance tips that help optimize MIG gun performance, keep production flowing smoothly and avoid unplanned downtime.

Laser Marking 101

How do you choose the appropriate laser for your marking applications? Here are several factors that must be considered and how they impact the end results.

How the Right Offline Tool Presetter Affects a Shop

The old saying “it won’t make chips – not worth it” doesn’t apply anymore. Considering the accelerating pace of change in technology and the relentless competition your shop faces, how can you possibly afford not to use a presetter?

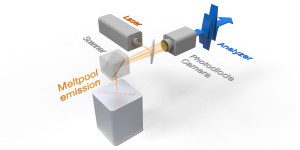

Metal Additive Manufacturing Meets Quality Assurance

Quality assurance and in-process monitoring are essential to move additive manufacturing from making prototypes into first-class shop production. Here’s how it works.

It Only Takes a Spark

Sparks may be unavoidable in your operations, but fires are not. Effective spark arrestance and fire suppressant technologies can dramatically reduce your potential fire risks. Here’s how.