Column

Filter by Process Zone:

Welding Abrasion-Resistant Plate: Three Common Challenges and Their Solutions

Here are some tips that make it easier to avoid cracks and prevent lost time and money when welding these incredibly hard plates.

Closing the Loop: Strategies for Bending Closed Forms

With a bit of creativity and thought to overcome limitations, it is often possible to form closed profiles and other difficult parts with a standard press brake. Here are some tips on how to do it.

The Importance of Proper Welding Operator Training

To gain more business in the face of a skilled labor shortage, fabrication shops need welding operators that are familiar with a wider variety of welding processes and materials and can take on new jobs to set their shops apart. Proper operator training plays a key role in reaching these goals.

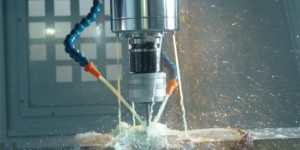

What You Need to Know Right Now to Improve High-Volume Micro Manufacturing

Opportunities abound for shops to cash in on the ever-growing micro machining market, but the differences between different types of micro tools vary from those found in standard tooling. Here are some insights into the extra care and know-how needed to achieve success and build a successful reputation as a reliable supplier of micro machined parts.

The Largest Qualified 3D Metal Part for European Aerospace is Here

How do you economically produce huge parts with intricate geometry that has a tendency to warp but must withstand critical applications in a demanding environment? Here’s the answer.

How Clean is Clean Enough? Evaluating Air Quality

Is your shop clean enough to fabricate components for medical devices? A proper diagnosis is necessary to solving an OSHA or FDA particulate problem. But before installing an air quality remedy, it helps to know your current particulate levels, exposure profile and airflow patterns. Let’s take a closer look at this evaluation process.

A Unique Partnership: Metal Additive Manufacturing and Conventional Machining

Here are five important aspects of the design and manufacturing process that everyone should understand to properly and successfully implement metal additive manufacturing within your company.

Considerations for Consumables in Robotic Welding Applications

Did you realize a contact tip often serves as a barometer of the overall effectiveness of the welding process by indicating how optimized it is – or isn’t? To prevent time consuming and costly issues with joint access, here are some important reasons why consumables must be part of the planning process when working with an integrator to design a robotic welding system.

Additive Manufacturing: Making Sense of Laser Metal Deposition and 3D Printing

Because metal additive manufacturing processes are complex and require extensive material and process knowledge, it can be difficult for a metal fabricator to see how or when 3D printing might fit. To help make sense of it all, let’s consider the basics of additive manufacturing and 3D printing and how it all relates to metal fabrication.

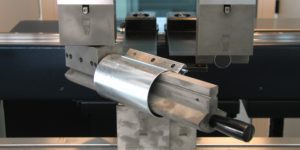

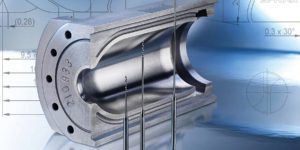

Take Care of Tool Holders, Prevent Cycle Disruption

There are three particularly sensitive areas of the tool holder assembly that can experience process-affecting wear and tear and cause a cycle to change. By identifying and addressing issues early in these areas, you can prevent small tool holding imperfections from turning into bigger problems.

Veterinary Medicine Adopts 3D Metal Printing

The durability and strength of metal, coupled with a nimble approach to product development and reduced lead times, are driving the widespread adoption of metal additive manufacturing for orthopedic care and prosthetics. Here is one example where 3D metal printing recently proved to be a truly lifesaving process.

A Sticky Situation: Four Mistakes in Oil Mist Extraction

Coolants and lubricating fluids are essential to metalworking operations. But if they are allowed to accumulate in the air, they can become a significant health and safety hazard. What can you do to minimize your risks?