Column

Filter by Process Zone:

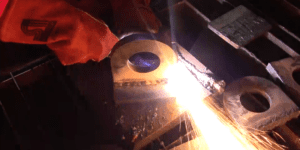

Approaching Removal Jobs from a New Angle

Efficient attachment removal has always been tricky. Without the ability to mechanically position the tool so that a closer cut can be achieved with less residual metal, workers were forced to deal with the drawbacks of traditional removal processes. But not anymore: A small alteration has made a huge impact on the attachment removal process.

Reduce Moisture-Absorption and Cracking Risks with Seamless Wires

Not every welding application requires the benefits that higher priced seamless wires provide. But when moisture must be controlled to help minimize the risk of hydrogen-induced cracking in demanding high-strength applications – and with it, costly repairs or potentially catastrophic weld failures – seamless welds are the ideal solution for the job.

How to Choose for Your Roll Former: Pre-Cut Vs. Post-Cut

Sometimes it’s equally as important to know what not to do as it is to know what to do. When it comes to investing in roll forming equipment and accessories, quality roll tooling designers must consider the possibilities for each customer.

Signs Your MIG Gun is Overheating – and How to Prevent It

Gun overheating can be a symptom of numerous problems, and it can result in catastrophic failure if ignored. Here are some common signs and causes of MIG gun overheating to be aware of that can help you prevent or quickly remedy the problem.

Laser Welding: How to Reduce Production Costs Before You Even Begin

Knowing how to utilize the increased flexibility gained through laser welding can enable a fabrication shop to tackle tough challenges and creatively solve them.

Zero-Point Workholding Systems: A Creative Solution for Many Manufacturing Operations

Think zero-point clamping workholding systems are only applicable to machining processes like milling? Think again. Because these systems can solve two of a shop’s toughest problems – repeatability of location from one fixture or workpiece blank to another, and quick transfer of work from one work area of the floor to another – the savings in setup time plus increased accuracy adds up quickly in a variety of operations.

Six Common Mistakes in Automated Brush Deburring

Here are some ways to avoid six pitfalls that shops must keep in mind when considering a switch from manual deburring to automated brush deburring.

Augmented Reality: Finding a Better Way to Screen and Train Welding Applicants

Shops can now create a welding lab experience without a lab by using new technology that simulates various welding processes and blends real-world and computer-generated images into an augmented reality environment for a realistic welding simulation that closely resembles live arc welding – and provides them with an objective means of measuring the skills of each applicant.

How Additive Manufacturing Enables Fast Modification of Molds

Direct metal deposition (DMD) with a coaxial powder nozzle can feed metal powder into a laser beam onto an existing three-dimensional surface to enhance surfaces, modify shapes, and restore damaged forming, punching, and injection molding tools and dies to like-new condition.

Stainless Steel Finishing: What You Need to Know

Understanding the specific alloy and how it will interact with different finishing processes can help guide you to choose the best finishing method for your application. Here are four key factors to keep in mind when finishing stainless steel.

NAFTA Renegotiation: Are You Prepared?

The agenda is being set and manufacturers have an opportunity to get the issues that matter to them on the table. Now is the time to consider how NAFTA benefits or harms your business. Analyze what might happen if those benefits or burdens are changed or eliminated, monitor developments and participate in the process. To get started, here are some of the significant issues likely to be on the agenda, and some ways to ensure that your business’ interests are represented at the negotiating table.

Buyer Awareness

Welcome to our annual Product Showcase and Buyers Guide.