Column

Filter by Process Zone:

Three Ways to Optimize the Automated Brush Deburring Process

Want to reduce costs, improve process consistency, simplify part assembly, increase edge strength and create a more uniform finish? A wide range of operations are good candidates for a switch to automated deburring, and following these steps can help optimize the process for efficiency, quality and productivity.

Gain Advanced Capabilities with a Versatile Multiprocess Welder

The need to weld many different material types and use different welding processes is increasing on the jobsite and in the shop. The ability to weld most any material – anywhere – with one lightweight, portable welding system that delivers industrial-level output can provide significant benefits for productivity, efficiency, and profitability.

How to Make the Right Reputation

In today’s highly competitive workplace, reputation makes a difference. It needs to be shaped and managed to reflect the way you want to be viewed. When all is said and done, your reputation is what you make it.

Electro-Chemical Weld Cleaning: It Makes More Sense

Where stainless steel and aluminum is concerned, there has been a drift away from traditional wire brushes and harsh chemical cleaning solutions in favor of more efficient, environment-friendly electrochemical weld cleaning technologies that make more economic and safety sense than other costlier, traditional and sometimes toxic methods.

Answers to Frequently Asked Questions About Filler Metals

Here are the answers to some of the most frequently asked questions about filler metals and welding best practices to help improve weld quality, productivity and overall welding success. These tips can help you make the right filler metal selection, address common challenges and get the most from your welding operation.

Beyond Bending: Press Brakes Can Do Much More

It might come as a surprise that the press brake you walk by on the shop floor each day can do a lot more than make flanges. When considering how to get from product drawings to finished goods, keep in mind that your press brake can do so much more than just bend.

Strong Supplier Partnerships are About Much More Than Price

A healthy relationship goes beyond a vendor’s ability to consistently deliver performance, reliability, quality and customer service at a competitive price. The key is putting the right people in place to foster mutual trust and flexibility. As our industry continues to evolve, so too must our relationships with our customers and suppliers.

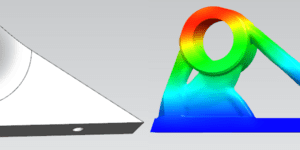

New Ways to Reduce Weight and Costs in Metal 3D Printing

To manufacture complex and efficient lightweight structures where every gram counts, FEM calculations and topology optimization can create even more efficient printed components.

The Right Flap Disc Can Save Time and Money

Selecting the right disposable flap disc to use for a specific grinding, blending or finishing job also minimizes the risk of removing too much material and ensures the best possible finish. To maximize flap disc effectiveness and longevity, here are several key factors to consider for choosing the right tool for the job.

Three Ways to Address the Welder Shortage

A lack of skilled labor may mean missed deadlines, a reduced ability to compete for jobs, higher costs and lost productivity due to rework. But new technologies and welding systems being designed by welding equipment manufacturers can help fabricators address these challenges, bridge the labor gap and remain competitive by completing jobs on time with high quality.

How to Get Ahead Faster – and Stay There

Getting ahead shouldn’t depend on lucky breaks, favoritism, or even hard work. It should be in our control . . . and here are some certain behaviors that will help you stand out from the crowd.

Buyer Awareness

Welcome to our annual Product Showcase and Buyers Guide.