Column

Filter by Process Zone:

How 3D Printing is Used to Help Fight Wildfires

Firefighters need high quality equipment that they can depend on, especially on the eve of wildfire season. For them, fast and effective water flow is essential, and here’s a closer look at how 3D printing and selective laser sintering technology helped redesign a water pump rotor three times faster than in the usual prototyping process.

Can a Quality Hinge Be Formed in a Press or a Brake?

Curls, hinges, knuckles, and rolled edges can all be produced on sheet metal using either a punch press or a press brake. The primary difference is the amount of control and handling provided by the machine. When producing curl forms, here are some factors to consider to make sure the job is done right.

Fit and Trimmable Flap Discs

Are you trying to blend and finish curved parts and other jobs where it’s difficult to reach the work or when a specific material finish is a priority? Trimmable flap discs are a versatile solution for these applications because the flaps and backing plate will also curve to match the shape during the process.

Is Pulsed MIG Welding Right for Your Operation?

Do you need faster travel speeds, reduced spatter levels and improved control over arc starts to boost efficiencies or improve your MIG weld quality? With some training and a little practice, pulsed MIG welding can drive the improvements you need. Here are some factors to consider whether it is a good alternative for your operation.

Self-Integrating a Robotic Welding System

To stay competitive, many shops must choose between building a robotic workcell or buying a turnkey system. DIY robotic integration is possible, but certain critical factors should be considered because the end user assumes greater responsibility and acquires more project risk. There is much to know and manage, from process welding requirements and robotic cell design to tooling requirements and system documentation.

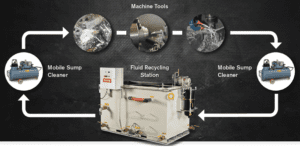

Coolant Recycling Takes Center Stage

Are you concerned about the rising expenses associated with your waste management? Do you need a more effective and profitable way to reclaim and recycle your valuable metalworking fluid? Modern fluid reclamation systems use innovations that can provide a fast return on investment while improving your profits, equipment life and employee safety.

Strategic Changes for Closing More Sales

What we first learn in our early training indelibly sticks with us for guidance. But new demands and expectations call for different ways to keep up and stay relevant. Here are five changes to consider.

How to Increase Sales in Job Shops and Metal Processing Centers

It’s easy to get caught up in the latest production technology, but sales are the fuel that keeps all of the systems on the shop floor running. To win new sales in the competitive fabrication market, here are three key areas where you can increase your chances to generate more business.

How the Right Flux Unlocks the Full Potential of Submerged Arc Welding

A wide range of fluxes are available for the SAW process, including some that are specially formulated to bring specific properties and characteristics to the finished weld. With so many types of flux available, how do you know which option is the best choice for your application?

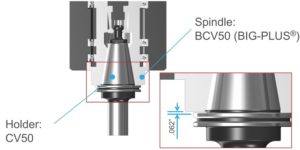

You May Have a BIG-PLUS Spindle and Not Even Know It

Many shops are unaware that a lot of their spindles are BIG-PLUS, so they don’t realize the capabilities they possess that this system provides. If you identify these spindles on your floor and want to start taking advantage of them, there are some things you should know.

Why Invest in a Tapping Tool?

Though there are less expensive methods for adding threads to sheet metal parts, in-punch tapping is far and away the fastest, most accurate way to produce threads. Ultimately, the decision comes down to the thread type, specification and how many tapped holes are needed.

Robotic Guidelines for the Production of Safety Critical Welds

Security features, tracking, arc monitoring and traceability make it nearly impossible to stray from established protocols and parameters that maintain weld integrity during the robotic welding of safety critical welds. It may take a considerable amount of upfront work to get to full data harmonization, but the results are confident customers and improved product quality that can help secure future operations.