Column

Filter by Process Zone:

Technical Service in the Era of Industry 4.0

As machine tool manufacturers work on enabling technology to make the Smart Factory possible, the field of machine service and support has started to drastically minimize the window of lost productive time that shops must deal with.

Yes, You CAN Automate Without a Robot

The average shop taking their first steps into automation doesn’t need to break the bank by investing in lights-out production with advanced robotics. There is a simpler, less expensive way to impact your bottom line.

Precise Metal Cutting to Prepare for Welding

Precise cutting starts with preparation. Here are three tips to help you optimize performance and produce clean, smooth, straight cut lines in preparation for welding to minimize secondary operations like deburring and cleanup, and help operators achieve better weld penetration for higher quality welds.

Increase Tool Life with Preventive Maintenance

Deliberately pull a die out of the stamping press for tool maintenance even though it is still producing perfect parts? That’s right. Don’t wait for that next emergency to shut everything down to put out fires. You can actually reduce downtime by regularly scheduling preventive tool maintenance that provides longer tool life, fewer scrapped parts and improved productivity.

Easy Robotic Automation for a Stronger Workforce and Better ROI

Smart manufacturing tools are helping shops of all sizes deal with labor shortages and production inefficiencies. When implemented and managed correctly, these tools can aid human workers, create a more productive workforce and increase overall competitiveness.

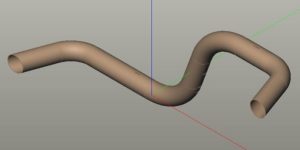

Consider the Big Picture When Manufacturing Complex Tube Assemblies

Fit-up, fixturing and assembly of multiple tubes can be difficult when coping, mitering and other secondary operations are required after bending. This is where new tube fabrication technology shines. Though it may bill out at a higher machine rate/hour, the time, material, tooling and labor it saves delivers a lower cost per assembly – and higher profitability.

Autonomous Machine Vision: The Total Quality Assurance Revolution

Flexible, easy-to-install and affordable visual quality assurance systems can inspect every stage of production, using artificial intelligence to self-adapt and self-adjust to changes. After reviewing samples, they learn – without any human interaction – all of the part’s attributes, surface characteristics, etc. and begin inspecting in only a few minutes.

There’s More to Equipment Financing Than Rates

The interest rate is a very small component of overall financing costs. It’s more important to match the lender to your overall financing needs. Here are some key factors that can help you find a good fit for a financing partner.

Don’t Let Low-Hanging Fruit Hold Back Your Sales

Choose to pursue this and fall into the trap of competing for business in the piranha-like pool of customers who treat every type of sale the same: price trumps quality, reliability, and guarantees. There’s a better way.

A Look Ahead

As the metal fabrication business remains strong, watch for more shops to adopt digitization, the principles of Industry 4.0 and integrated process flow as they move toward smaller batch sizes, shorter lead times, high-mix parts to compete – and to address the lack of skilled labor.

Welding High Strength Steel

Here are some answers to frequently asked questions about the process of welding this material, along with insights to help you improve your weld quality and increase your productivity.

May the Press Force Be with You: Tips and Tricks for High Tonnage Bending

Bending thick plates requires more attention to certain details than lighter bending jobs. Here are some ways to get all your ducks in a row before you bend the first part, so that your job will go more smoothly and translate into more profitable production.