Column

Filter by Process Zone:

How to Improve Productivity and Performance of Field Welded Moment and Column Splice Connections

These best practices for welded moment connections and column splices in the field require an up-front investment of time and money, but considering how much you’re likely leaving on the table, it’s a small price to pay.

Next Steps in the Digitalization of Tooling and Its Impact on Operators

Digital tools are already here in the form of DROs and one-way communications to mobile devices, but that’s only the beginning. Get ready for some exciting breakthroughs in automation that promise higher productivity, increased safety, greater throughput and less scrap.

Stay Sharp for Maximum Tool Life

To prevent lower quality parts and frequent tool replacement, keep your punch press tooling sharp and well maintained to achieve the greatest number of hits possible for the best possible return on your investment.

Finding Balance: Robotic Machine Tending Tips

Robotic automation of machine tending can add value to operations in more ways than one. By considering these concepts and combining best practices with high performance robots and peripherals, operational inefficiencies will diminish, paving the way for a more productive future.

Compensation for Dimensional Accuracy in Laser Tube Cutting

This is now a defining element in laser tube processing as shops compete within narrower pricing margins to meet product demands for improved quality and enhanced features. Here’s why.

Three Considerations When Purchasing Equipment

Here are a few things to consider before shopping that will help you find the equipment and terms best suited to your needs.

Think Like a Customer or Lose the Sale

Conventional wisdom tells salespeople to put the customer first, but never think like them. But here’s why that simply doesn’t ring true.

Seven Critical Steps for Submitting Samples for Electropolishing

Recognized for the uniform, bright polish it leaves on metal surfaces, electropolishing is highly effective for finishing small, complex, fragile parts as well as larger parts. To properly test its effectiveness, it’s important to submit your sample parts in the correct way to ensure the best results.

What You Need to Know About Weld Anatomy and Joint Geometry

Are you wasting lots of time and money on welds that are larger than they need to be, particularly on thicker materials? Or dealing with inconsistent quality or increased crack sensitivity due to welds with improper dimensions? There are many different ways to design welds that strike the best balance between weld quality and productivity.

The Practical Impact of Industry 4.0 – Part 1: The Digitalization of Processes

Anytime you must “go and see” something that could be transmitted electronically is an opportunity to connect. Anytime you read data from one place and copy or send it to another is an opportunity to automate. And here’s the great thing: If you are just starting out, it’s pretty easy to take small steps.

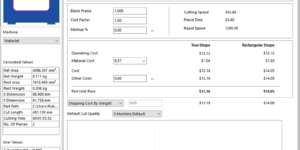

Show Me the Money: Costing and Quoting in the Metal Fabrication Industry

Few factors have a bigger impact on the sales, health, and bottom line of your business than costing and quoting. Most of us realize that if we set our prices too high then our products and services will not sell, but the problem is often the opposite: we price too low. How do we set prices?

Tool Measuring Systems and RFID Working: A Powerful Combination

Efficiently moving information around your shop floor is more important than ever. Connected through RFID, a shop can now use a tool presetter to monitor things never monitored before and use that data to fine-tune processes, reduce inefficient costs like scrap and waste, and make the factory floor smarter, streamlined, far more efficient and competitive.