Column

Filter by Process Zone:

Weld Functions You Should Be Using

Welding and fabrication are complex processes that can greatly benefit from robotic automation. While each application will differ in complexity, the consistent and effective use of certain weld functions can improve quality and enhance productivity while decreasing costs.

Capital Equipment Financing Options to Grow Your Business

Not all capital should be financed the same way, and not all capital funding sources are created equal. An assessment of short-term and long-term needs will help determine which loan type, structure and financing entity is best suited for your company and your expansion needs.

To Beat the Skills Gap, Join the Control Conversation

Machine tools with advanced conversational programming capabilities supported by comprehensive training serve as a bridge across the skills gap, a way to bring new professionals into the industry and keep manufacturing alive and well in North America.

Top Problems with MIG Welding Consumables . . . and How to Fix Them

Take a close look at the impact of welding consumables on your overall operation, not just the purchase price. Here are some key tips on how to properly select, install and maintain consumables and troubleshoot problems when they arise – and, better yet, how to prevent them in the first place.

The Practical Impact of Industry 4.0 – Part 2: Automatic Manufacturing

Last time we saw how Industry 4.0 uses automated software to control and simplify the flow of information and tasks. Now let’s explore how it uses automated hardware to control and simplify the flow of materials and goods.

Stamping AHSS Got You Down? Reconsider Your Tool Design

To reduce wear and tool breakage when forming or blanking AHSS material, here are some tips on revisiting the type of tool steel used, the design of the tool itself, and whether or not adding a coating or surface finish will improve performance and provide longer tool life.

Added Value: The Importance of Aftermarket Care

You’ve covered every detail in upfront costs and factory floorspace, but what about technical support and service after production starts? Whether buying one robot or hundreds, having access to diverse support services to ensure peak robot performance is vital to maximizing your return on investment. Here’s why.

Pro Secrets for Maximizing Grinding Performance and Efficiency

To significantly reduce your operating costs, achieve better productivity and a stronger bottom line, here are some tips for properly using abrasives that will eliminate waste and improve performance, efficiency and operator comfort.

Five Best Practices for Multi-Material Welding in Manufacturing

To stay competitive, more shops face the challenges of welding many different types of materials. To reduce setup times and help their operators produce high-quality welds, they must move beyond basic options and invest in advanced capabilities that can have a big impact on the bottom line.

Cleanliness is a Virtue

This old proverb rings true for your plant more than ever: Take a closer look at how good housekeeping practices positively impact profit, productivity and purpose in metalworking operations.

How to Keep Your Sales from Running Out of Gas

Closing sales is the goal, but that takes keeping the prospect tank full of gas. So what can you do about it?

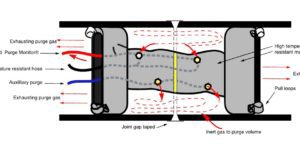

Welding New Nickel Alloy

Inconel 740H and other new superalloys provide major improvements in mechanical properties and corrosion resistance at elevated temperatures, but they still need careful purging during welding in order to preserve these characteristics.