Column

Filter by Process Zone:

How Safe Use of Cutting and Grinding Abrasives Benefits Productivity

Some operators learn as they go or get advice from coworkers who may (or may not) have received appropriate training. Unfortunately, learning about abrasives through trial and error can cause unnecessary accidents and injuries while negatively impacting productivity and costs.

Four Tips for Developing an Effective In-House Welder Training Program

Even seasoned welders don’t always remember – if they ever learned – all the basics regarding techniques and materials. Optimize fabricating operations and help plug your future skilled-labor gap by instilling good habits from the start.

5 Ways to Calculate Your Actual Welding Costs

Tracking equipment purchases, labor hours, filler metal, and consumables is obvious and relatively straightforward. If you’re like many fabricators, though, you’re probably also budgeting for expenses you shouldn’t have to incur.

Busted: 5 Myths About Metal-Cored Welding Wire

Metal-cored wire isn’t new, but there are often misconceptions about applications, cost, performance, strength, and workability compared to solid wire. Read on to learn how you might be missing opportunities to increase welding operation productivity for less cost.

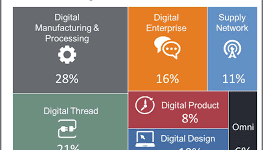

Meet the Juggling Juggernauts

Overwhelmed about where and how to start digitizing? Relax. Rome wasn’t built in a day, either.

How to Prevent Common Causes of Poor Weld Wire Feeding

Identifying the culprit can be complicated. Luckily, premature consumables failure, burnbacks, and bird-nesting are often easily resolved – so you’ll soon be welding again.

Benefits of Using a 5- or 6-Inch Grinding Wheel or Flap Disc

More fabricators are using larger-diameter grinding wheels and flap discs for their grinding, material removal, and blending applications instead of 4.5-inch options — and with good reason.

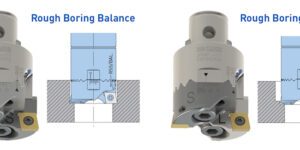

Selecting the Right Lead Angle and Insert for Boring Tools

The rules for twin-bore roughing and single-point fine boring are similar – but not the same. Lead angles close to 90 degrees more effectively combat potentially damaging chatter and vibration because they apply the least amount of radial pressure against the tool.

Upsizing with Jigless Welding

Greater robot payloads are opening the door to automatic fabrication of large, unwieldy components.

Four Tips to Increase Arc-On Time

Consider the process as a whole from start to finish. Activities before and after welding, such as part fit-up and post-weld grinding, affect how much time welders actually spend under the hood.

WE’RE RETOOLING

New year, new decade, new opportunities, new editor. Allow me to introduce myself.

Bank on Better Abrasives

A 20% increase in consumable costs reduced an automotive component supplier’s cycle time by 30% and is saving almost $250,000 annually on machine operating costs.