Column

Filter by Process Zone:

Quality 4.0 is Achievable When Systems and Culture Merge

Nothing frustrates improvement efforts like software programs that don’t play well together. Brothers Brian and Mitch Olson made sure that didn’t happen when they launched their CNC machining shop by deploying a solution that integrates resource planning and quality management.

It Might Be Time to Use a Flap Disc Instead of a Standard Grinding Wheel

New technology is making the flap disc a cost-effective and equally effective alternative to grinding wheels in a variety of applications. They’re versatile, lightweight, easier to control, and convenient.

How to Solve 8 Top Problems that Undermine Profitability in Metalworking Operations

Every ounce of additional productivity rung from each step in the process adds up to significant cost savings over time. From coolant and tooling to programming and scrap management, opportunities to increase efficiency abound.

You Can’t Create a Comprehensive Digital Thread If You Let This Common Obstacle Get in the Way

Quoting software saves time and money throughout the entire production process if it’s properly integrated with CAD/CAM and manufacturing system software. If it’s not, your team’s doomed to constantly reinvent the wheel.

Tips for Eliminating Back Purge in Stainless Steel Pipe Welding

Switching to a modified short-circuit MIG process instead of TIG for the root pass saves time without compromising an operator’s ability to produce high-quality welds that meet code requirements. Your shop will also save money on consumable costs.

Will the Real Collaborative Robot (aka Cobot) Please Stand Up?

A robotic system is ‘collaborative’ only if all elements – robot, tooling, workpiece, and work area – meet international safety standards. Depending on application, you may be able to turn a standard industrial robot into a cobot and comply.

For Digitization in Manufacturing, the Show Will Go On

Not even a pandemic can interfere with metalworking’s inexorable technological progress. Blowing way past automation, entrepreneurs are harnessing digital know-how to solve analog problems — wherever they find them.

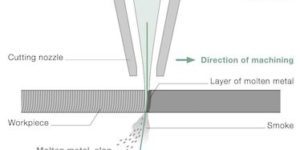

Laser Cutter That Thinks for Itself Opens the Door to a Fully Automated Process

Trumpf’s Active Speed Control uses artificial intelligence to completely eliminate the need for an operator to monitor cutting and, if necessary, tweak parameters. The technology automatically adjusts feed rate to ensure part quality when cutting plate with chemistry, thickness, or surface condition variations.

Easy Wins: Adapting to a New Manufacturing Reality

As many fabricating and metalworking companies seek to revitalize production in these trying times, a new sense of urgency is prompting creative approaches to automation. While each shop will forge a unique path to its own new reality, they’ll share common challenges and solutions.

Auto Racing-World Manufacturer Cuts New Path to Profitability with Automated Metal Cutting

The world’s top engine builders and auto enthusiasts rely on Borla Performance Industries exhaust systems, but parts were taking too long to program and produce. Switching from CNC machining to automated plasma cutting is drastically reducing cycle times.

How to Optimize Sawing Operations

A sawing specialist asks and answers four basic questions about feed rate and feed pressure, blade life, determining cutting feed and cutting speed, and optimizing tooth selection.

Where There’s a Mill There’s a Way – Online Marketplace Reboots Machinist’s Career

Todd White started to do a couple jobs a month with one Tormach machine in his garage. After qualifying to become a Xometry manufacturing partner, he’s become a full-fledged shop with multiple machines and work for a wide variety of customers.