Column

Filter by Process Zone:

Abrasives Are Not All Created Equal

Many shops hesitate to incorporate abrasive finishing tools in CNC machines for fear of clogging coolant lines and damaging slides and bearings. However, finishing tools generate very little grit.

5 Common Questions About Implementing a Robotic Welding System

Proper cable and consumables selection and tool center point (TCP) control play go a long way toward improving quality and optimizing overall equipment effectiveness (OEE). Establish a thorough pre-implementation plan and monitor key issues to get the most of your investment.

Appearances Can Be…Achieving!

Everyone’s ready for a fresh start this year, but one company isn’t leaving 2021 outcomes to chance. A dynamic new marketing approach for 120-year-old Jarvis Cutting Tools included a logo redesign, a bold undertaking led by an industry outsider.

By Doubling Down on People, Mold Maker Doubles Down on Sales

Connecticut mold maker Ray Coombs put capital investment on hold for five years to work with the local educational and manufacturing communities to solve his labor problems once and for all. Then he added three new machines that are helping to cross-train employees for record sales.

When (and How) to Automate Sheet Metal Welding

Cobotic welding systems occupy the gap between fast and heavy industrial robots and manual welding. They also challenge the paradigm that welding automation is strictly a high-volume game.

The Rise of Trochoidal Milling: More Accessible Than Ever

Circular machining with low radial engagement and constant feed per tooth extends tool life by minimizing heat and vibration when machining extremely hard materials. CAM and control developers are making it easier for any size shop to add this technique to their capabilities.

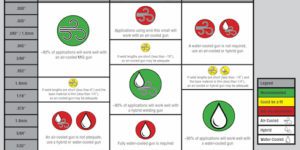

Metalworking Fluid Isn’t Just Another Consumable

Formulators spend significant resources to develop coolant that optimizes a machining process based on what materials, machine, and tooling a manufacturer is using. Don’t miss out on the product’s strategic value by being pennywise and pound-foolish.

Why You WANT Variable Gage Analysis (GR&R) Results

Some manufacturers shy away from conducting gage repeatability and reproducibility (GR&R) studies because the results are inconsistent. But because variability is unavoidable, your goal is to calibrate that measuring device to consistently return an acceptable range of results.

How to Become a Multipass Welding Master

Multipass welds are often required in pipeline, ship, heavy-duty structural and pressure vessel construction. Selecting the proper abrasives and cleaning properly between each pass can help optimize results, saving the operation time and money.

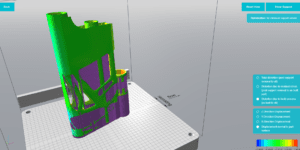

We’re Closer Than Ever to First-Time-Right 3D Metal Printing

In its drive to develop an end-to-end solution for additive manufacturing, Siemens Digital Industries Software offers tools that simulate the printing process at various levels. To minimize the expensive quality-refinement process, modules identify and correct areas of malformation and shrinkage.

Maximize Your Investment in a Welding Cobot

A collaborative robot (cobot) welds more efficiently, more consistently, and has a longer reach than its human counterparts. Here’s what to consider as you shop for a model that will boost your operation’s throughput and quality.

Four Business-Management Best Practices the Pandemic Taught Metal Manufacturers

Last year’s unprecedented economic and supply chain challenges underscored gaps in commonsense contingency planning. Manufacturers that take heed of these lessons learned will be better prepared for whatever crisis may arise.