Column

Filter by Process Zone:

Tips for Safe Use of Abrasive Cups, Cones and Plugs

Choosing the right product for heavy material removal or getting into hard-to-reach places goes a long way.

Measure Twice, Weld Once

Pre-build calibration is critical to part quality for metal additive manufacturing, and the process is easier than ever.

Don’t Overlook the Most Important Piece of the ER Holder Puzzle

It turns out, nuts are the most important pieces in ER collet systems.

Data Driven Production, from Order Entry to Execution

Break data into small segments in order to develop good data, resulting in better solutions.

Sneak Preview Fabtech 2021

Back in action! Fabtech returns to Chicago.

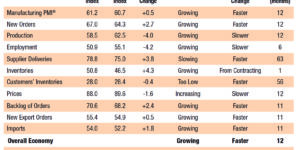

Manufacturing’s Optimistic Outlook Continues to Soar

As the nation’s economy reopens, the manufacturing sector will be a major player on the road to prosperity. Buckle up.

Five Things You Need to Know about Smart Manufacturing

Leverage machine learning to make better decisions in real time.

The “Smart Factory Five” for Robotic Automation

There are key areas manufacturers must be mindful of when creating a completely integrated smart factory, especially where robotic automation is concerned.

Consistent Consumables

Take a peek into the latest product developments regarding consumables.

Best Practices for Welding Wire Spool Selection and Setup

Deciding on the appropriate welding wire spool for your job results in productivity, efficiency and profitability.

Improve Productivity by Preventing Five Common Welding Problems

Common problems in the weld cell can be costly and time consuming. Optimize your setup and efficiency so troubleshooting goes much faster when issues develop.

Smart Stuff: Driven by Data, Machines and Tools Almost Think for Themselves

Bill Berutti, CEO at Plex Systems, sums up the status of manufacturing and digitization: “Smart manufacturing isn’t something that will happen years down the road … it’s real, it’s imperative and it’s happening now.”