Column

Filter by Process Zone:

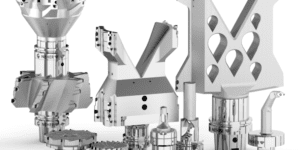

Set Your Gears in Motion

Innovative tools and equipment are available to support today’s gear manufacturing processes and keep the wheels of production spinning.

Laser Welding Made Even Easier

Laser welding allows your team to produce narrow deep welds, commonly used in high volume applications, at fast speeds.

How Automotive Robotics Paved the Way for Modern Automation

Demand for automation continues to escalate as companies search for ways to optimize operations — at this time only a small percentage of factory work is automated. Factory automation has come a long way — where to next?

AI Isn’t Going to Take Your Job, But It Will Make You Better at It

Artificial intelligence and machine learning will continue to influence and disrupt manufacturing, generating processes that get smarter with each new software and computing development. Manufacturing simulation has a key role to play.

3D Printed Tools Make an Impact

3D printing technology is becoming more mainstream. For example, AM allows for a high degree of freedom when designing a tool for a particular application.

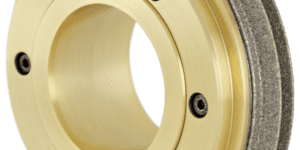

Tips for Overcoming Six Common Surface Grinding and Cutting Problems

Save money and time by selecting the proper abrasive designed for the type of thickness and material, as well as application requirements, for the job at hand.

Robotic Machine Tending for Optimized Operations

An increasing number of facilities are using flexible, portable robot platforms, which can be maneuvered throughout a factory to perform tasks. By robotically automating one or more elements on the shop floor, machine shops can not only increase productivity and OEE, but also realize a better ROI.

Ten Integrations Every Manufacturer Needs With Their ERP

The ability for an ERP system to integrate with third-party Internet of Things technologies has become one of its most important features — and a powerful competitive advantage.

Meet Dot Matrix: A Basic Tool of Industry 4.0

From the factory of origin to the final destination, dot-matrix codes can help track, trace and inform everyone in the product lifecycle. The dot-matrix code really is one of the most basic, and important, tools of Industry 4.0.

Five Tips for Robotic Welding Process and Project Planning

Planning for a robotic welding project should focus on the process and the specific project. After following these tips, conduct a trial to gauge problems before you start full production.

Communicate, Diversify and Be Creative

There is a bright side to the challenges machine shops are dealing with. Get ahead of the issues and the positives in the manufacturing economy will see you to the other side. The experiences of a die stamping company in Connecticut may sound familiar; learn how their pro-active measures are making a difference.

Innovations Power Up the Arc

Advances increase both power and performance in arc welding, including the ability for users to cut through thicker material, as well as gain better control at the arc to improve safety and productivity.