Column

Filter by Process Zone:

Smart Safety Strategies

Advances in safety equipment prevent accidents and ensure your employees remain healthy and ready to work.

Tooling and Workholding Solutions Offer Versatility and Reductions in Costs

Handle the toughest applications and cut down on the number of changes thanks to advances in tool life.

Achieve Consistent Welding Output, Repeatable Processes and Precision Welds

Achieve Consistent Welding Output, Repeatable Processes and Precision Welds

Elevate Your Shop’s Material Handling Practices

Robots, automated storage and retrieval systems, and electric forklift models ensure efficient material handling processes within your shop.

High Speed, Accurate and Easy to Use Measurement and Inspection Tools

Thanks to the latest innovations in M&I, your shop can easily conduct high levels of quality assurance.

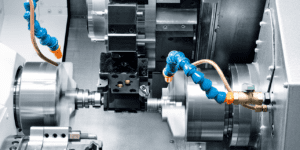

Take Advantage of Short Cycle Times and Accurate, High-Precision Machining

Progressive and innovative metal-cutting machines and software speed up your processes by reducing cycle time and enhancing productivity.

Blend Better, Work Better: Get the Most out of Your Flap Disc

Selecting the right shape of flap disc will help operators get the job done faster, allowing them to achieve a smoother and more uniform finish without gouging the workpiece.

The Role of Assist Gases in Laser-Cutting Applications

There are variables that impact your assist gas choice. As the use of compressed air as an assist gas in laser cutting continues to increase, fabricators need to understand which gas is best for which application.

Momentum is Building

Optimism proliferates for construction equipment manufacturers, spurred by federal funding of infrastructure projects and other factors. Here’s what to expect.

Precision Results: How to Select the Right TIG Torch for You

By understanding the distinct types and features of TIG torches, as well as expendables and the workpiece, you can pick the perfect torch that suits both the job and your work style.

Welding Systems Ready for Every Challenge

The next generation of welders, guns and torches are prepared to handle your job shop’s application challenges. The latest innovations and advances in MIG/TIG welders, guns and torches link fabricators to a wide range of products to successfully overcome hitches in the fabrication process.

The Cobot Difference: The Benefits for Small Shop Adoption

Cobots are helping job shops thrive. Thanks to advances in technologies, cobots help where welding workspace is tight and/or capacity needs a boost.