Column

Filter by Process Zone:

Seven Smart Questions to ask Before Buying a Presetter

Presetters are data centers that can automate measuring cycles, capture, save and distribute measurements.

Next Steps in Tool Presetting

Tool presetters are an accurate way to ensure proper tool dimensions, reducing waste and unplanned down time.

Manufacturing’s Automated and Digital Future

The positively charged metalworking industry continues to implement and invest in technologies that will prepare them for whatever 2023 may bring.

Welding, Welding Automation, Robotics & Industrial Automation, Tube & Pipe

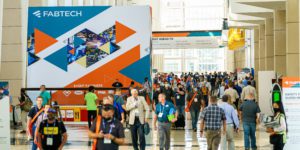

Welding, robotics and automation will be featured at Fabtech in Atlanta.

3D/Additive Manufacturing, Forming & Fabricating

3D and additive manufacturing solutions will be displayed at FABTECH.

Manufacturers Remain Persistent and Push On

FABTECH 2022’s attendees can view the latest machinery and software innovations and find the tools and new solutions that will assist them in improving productivity and increasing profits. Many exhibitors will unveil new or updated machinery or products and services.

FABTECH 2022: Where Innovation Meets Opportunities

FABTECH to Take Place at the Georgia World Congress Center in Atlanta from November 8-10!

Preparing for Disruption to Ensure Long-term Success

Disruption, good or bad, is a factor when conducting business. Ensure your shop is financially prepared to deal with the challenges and the opportunities.

The Big Benefits of Small Hand Tools

These small but powerful machines help small fabrication shops leverage their workforce to be more productive, and they complement the big, advanced production systems found in more automated factories.

When is it Time for Fixed, Cobot or Automated Welding?

Taking the time to carefully plan for this investment is important. Look to a provider for assistance and for help determining the expected payback.

Non-woven Abrasives Optimize Finishing while Reducing Grinding Steps, Increasing Productivity

Modern abrasive grains and stronger bonding methods found in the latest non-woven abrasives enable shops to quickly achieve desired surface quality.

Introducing Clean Tube Laser Processing

Automatic spatter protection represents a significant increase in productivity when utilizing tube laser cutting lines.