Column

Filter by Process Zone:

Resistance Welders are Optimized for Performance, Productivity and Cost-Effectiveness

Economical and streamlined resistance welding equipment is offered in pre-engineered as well as customized solutions.

CMMs: Indispensable Tools Ensure Precise and Comprehensive Measurement

CMMs are invaluable in industries where quality and compliance with specifications are paramount.

Five-Axis CMMs Streamline and Automate Parts Inspection and Measurement

Labor shortages, automation, and need for nimble parts inspection drive adoption of CMMs.

Autonomous and Scalable Lift Trucks Solve Your Specific Challenges

Advances in lift truck technology ensure your operators are responsive to the dynamic conditions at work in your shop.

Right Angle Grinding Abrasives Make Giant Performance Leap in Challenging Applications

New engineered shaped ceramic grain stays sharp and keeps cutting with no significant increase in pressure throughout the life of the disc.

Machining: Optimize the Solutions

Discover what’s next for machine tools. It may be just the time to update your shop’s metal removal technologies and processes.

How Best to Benefit from Automation, Flexibility and the Resulting Efficiencies

New advancements in the machine tool sector overcome challenges and optimize a shop’s operations, just in time to support a forecasted uptick in the manufacturing economy.

A Customized Grinding Solution for Tap Manufacture

High-end tap producers are enhancing designs to meet the escalating market share of specialized materials required by high-tech industries, which calls for customized and tailored designs.

Flap Discs: The Right Selection and Technique Can Save Time and Money

Even though flap discs are disposable, there are steps that can be taken to lengthen their usability. The result is less downtime, more work and greater savings.

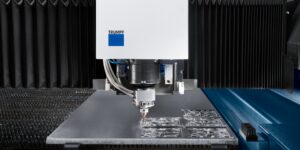

Ultra-High-Power Lasers Tackle Ultra Heavy Plate

With more than 20 kilowatts of power available, cutting thickness limits can be pushed to as thick as 2”, allowing fabricators to bring the speed, precision and cutting quality of the laser to a new range of parts and products.

Addressing Common Concerns: Solutions to Support Operators Throughout the Welding Process

When you’re on the job, there’s bound to be a mishap from time to time. What matters most in those moments is the solution you choose to fix it.

2024 Metalworking Risk Roundup: Inflation, Weather, Workforce

Elevated costs, materials, and labor headline a series of financial risks and insurance considerations for the industry.