Column

Filter by Process Zone:

Waterjet Cutting for Multiple Materials

For fabricators in search of new opportunities, and for customers who want shops that provide greater value, waterjet cutting is too important to overlook.

Stay on Top with Dynamic, Pioneering and Agile Cutting Systems

Investing in cutting systems driven by advanced automation capabilities and intuitive controls is a strategic move for fabricators looking to boost performance, manage waste and reduce costs. Laser Cutting Machine Outperforms Higher Wattage Lasers at Lower Operating Cost AMADA AMERICA…

Tackle New Materials with Confidence Thanks to Breakthroughs in Abrasive Solutions

A wide range of industry sectors benefit by embracing newly developed products to elevate their metal removal and finishing processes.

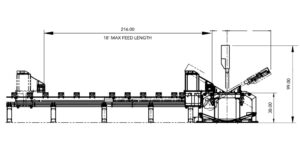

Sawing Systems Optimize Cutting Parameters and Monitor Cutting Processes

Real time monitoring systems track the performance of band saws, correcting the process to minimize disruptions.

Cost-effective Monitoring Systems Provide Thorough and Clear-cut Assessments

Make timely decisions regarding tool changes and adjustments to machining parameters with powerful monitoring systems.

Metalworking Holds Steady by Creating New Opportunities

Expansion and job growth announcements demonstrate unwavering commitment to U.S. manufacturing.

When Pretty Welds Aren’t Enough

Shops struggling with outside disruption and competitive pressures should look into robotic automation as these techniques continue to make significant advancements.

Parts Marking Guarantees Traceability and Quality Control

The integration of part marking solutions brings several advantages including durability and longevity.

Abrasives Leap Forward: Extending Product Life Spans and Enhancing Performance

Inventive and next generation abrasives are having a transformative effect in shops that rely on the products for any number of applications.

Flexible and Adaptable Machines Allow You to Compete in a Rapidly Evolving Landscape

User-friendly automated metal forming solutions are leveling the playing field for small to mid-size fabricators in several ways.

Versatile Heat Treating Systems Handle Diverse Applications

Continuous and controlled environments for the heating of metals ensure consistency and high-quality treatments and solutions.

Quickly Adapt to and Utilize Robotic Technology Via User-Friendly Programming

As robotics and automation technologies continue to advance, these systems will play an even more vital role in shaping the future of metal cutting production.