Column

Filter by Process Zone:

Financial Justification: Achieving a Two-Year Payback with Robotic Welding

Deciding whether to convert manual or semiautomatic arc welding stations over to robotic welding is typically driven by the payback or return on investment achieved through labor savings. But Geoff Lipnevicius of Lincoln Electric explains that labor savings do not comprise the total anticipated savings and shows how they are generated from a variety of other process-related areas.

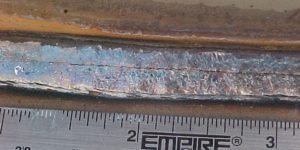

Basic Tips for Understanding (and Preventing) Common Types of Weld Cracking

The best defense against weld cracking is to understand its causes and solutions. And he shows why the best place to start is by understanding hot cracking and cold cracking.

Spindles By (External) Design

Ed Zitney of SKF Machine Tool Services explains why understanding how a particular machine tool spindle design will benefit an application can provide a big assist in helping to realize its ideal operation and performance consistent with the job at hand.

Training 101: Starting Out By Starting Right

The Piercing Process: Bob Pugliese of Trumpf shares some tricks of the trade for creating smaller holes in thicker steel plate using a laser.

THE BASICS OF SAFETY: CONTINUOUS IMPROVEMENT AND SAFETY

By questioning the value and return on investment of departments, organizations are certain to eliminate redundant efforts between quality, lean, and safety groups. In Part 5 of our series on Back to Basics in Safety, Phil La Duke of Rockford Greene explores the shared role between continuous improvement, lean principles, and safety.

LESSONS LEARNED IN GTAW QUALIFICATION TESTING

To emphasize the importance of the effects of welding heat input and cooling rate on weld mechanical properties, Regis Geisler of Lincoln Electric analyzes another application where a one percent nickel electrode was successfully implemented in a welding application.

CNC CAN MAKE YOU A MULTI-TASKING ASSET TO YOUR COMPANY

Attention Operators: Today’s advanced CNC can look and feel the same way, whether on grinders, milling machines, lathes or another machine tool, and also on press brakes, lasers, welding systems and other fabrication equipment . . . get the picture? Randy Pearson of Siemens Industry explains how and why.

TOUGH TIMES: THE IMPERATIVE FOR PROCESS CONTROL

Mike Riley presents a simple model from industrial metrology supplier Renishaw Inc. that explains the sources of process non-conformance and the process control methods to address them – something manufacturers will need if and when times get tough.

Selling Safety, Revisited

Phil La Duke of Rockford Greene explains why and how Safety must distinguish discretionary spending from non-discretionary spending and be prepared to explain why a safety initiative must be implemented immediately instead of waiting for a better business climate.

Probing Thoughts About, Well, Probing

Sophisticated CNC can do much more than just find the edge for you. Randy Pearson of Siemens Industry shows how it also improves part production and repeatability on prismatic and complex 5-axis jobs alike . . . and it keeps score!

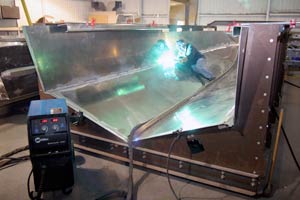

Troubleshooting the Wire Feed System

Accurately troubleshooting problems with the delivery of the welding wire to the weld pool and the current to the wire when they arise or, better yet, avoiding them before they arise, is crucial to maximizing the benefits that these processes offer.

Shedding Light on Light Curtains

It is not a difficult engineering challenge to design effective safeguarding for virtually any type of machine. Sergio Aguilar of Omron STI explains how the real challenge is to provide guarding that will deliver high levels of safety while also enabling high productivity and throughput.