Randy Pearson

Articles by Randy Pearson

Making a List, Checking It Twice

Returning your machine or a program to its original condition can now be as simple as saying “big data.”

3D, Robots, Big Data and a Few Memories

Looking back at IMTS 2014, we all got a peek into the future of additive manufacturing and process chains, plus a few exciting concepts that are going to find their way into the operation of your shop very soon.

Going in Forward and Reverse

The entire machining process chain can now be run in art-to-part simulation, with feedback and corrections made from end-to-end.

Hybrid Machine, Standard CNC

As the era of additive/subtractive machine tools emerges, Randy Pearson of Siemens Industry explains how today’s controls are well suited to handle the challenges.

Your CNC: OEE On Steriods

Your CNC has a learning curve, and you might be surprised by all it can know and tell you now, to help you run a more efficient shop floor or production department.

CNC Collision Avoidance

Sound the Alarm: More advanced CNC units provide full collision avoidance for both the machine builder and the end user alike, thereby protecting both the machine and the operator.

Robotic Integration

CNC allows the full and scalable integration of a robot into any machining operation, allowing shops and large production departments alike to do so much more.

CNC Access Security

In an age of compromised files and records, your CNC can be one safe place. There’s more than a password involved: soft keys, key switches and conventional keyboards alike can be used to structure CNC security levels, enabling machine operators, setup personnel, maintenance technicians, programmers and master control personnel varying degrees of access to programs, tool settings and more.

What’s in a Name?

The bard thought not much, but “CNC Machinist” has never meant more than it does today. Once relegated to an overhead expense, Randy Pearson of Siemens Industry explains why training is now absolutely vital to your success, both in the classroom and in the shop.

CNC Safety . . . Integrated On Your Machines

Nothing is more important than protecting your people, your programs and the machines in your shop . . . and the CNC can help you, in many new ways!

Advanced Surface Moldmaking

Theory becomes practice with the latest CNC technologies in your shop.

High-Speed Cutting in a Single Look

Here’s how having all of the motion control elements on a single screen helps tool and moldmakers to master their craft more accurately and efficiently and increase their profitability.

All Hands On… Screen

The onset of robotics in machine shops both big and small has significantly impacted the CNC to a great degree already, but more changes are on the way.

A Rising Tide Lifts All Boats

Through the cooperation of CNC suppliers, machine tool builders, educational institutions and end users, the machine tool industry is improving its workforce – and itself.

Continuing Education… On a CNC?

Randy Pearson of Siemens Industry explores how shop owners and major machining departments are discovering the untapped and potential enhancements for worker skill sets.

Hot Keys, Sans Piano

CNC function keys now offer advantages to programmer, operator and maintenance personnel alike.

No Chips, This Time

As technologies merge and metal fabrication applications grow more complex, CNC is now becoming a powerful alternative solution to PLCs for builders and users of metal forming and “non-traditional” machine tools, such as EDM, abrasive waterjet and others.

True CNC Tool Management: From Set-Up to Final Finish Pass

There once was a time when a tool was needed to redo a section, that it might have taken several minutes to recall the program, find the right tool number, identify the proper path and redirect the operation. Not anymore. Randy Pearson of Siemens Industry explains why.

Breathing New Life Into Old Iron

Retrofitting those old knee mills and lathes is now faster, easier and less expensive than ever, plus you get other big-time operating advantages.

Macro Programming… Keeping It All “In the Family”

Through the use of standard canned cycles on today’s advanced CNC, Randy Pearson of Siemens Industry shows how the programmer can use much higher levels of language without the need for custom writes, when transitioning among part family members.

Cut and Paste Program Changeover

Here’s how job shop multi-taskers and busy machine operators can pull information from existing server files off a network, flash card or memory stick and fill in the blanks to be up and running faster.

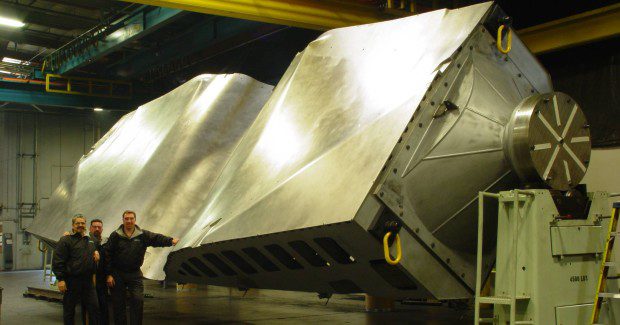

A Look Back, A Look Ahead

Randy Pearson of Siemens Industry reflects on IMTS 2012, one of the best shows he’s ever attended (and he doesn’t exaggerate) . . . and how it points to the future for CNC and its use at your shop.

A New Horizon in High Speed Cutting for Mold and Medical

Randy Pearson of Siemens Industry explains how what once seemed to be a far-off machining goal for mold and die work and medical parts is now a reality based on the advancement of new technologies.

Drive Diagnostics and Your Maintenance Tasks

Hang onto your stopwatches, Randy Pearson of Siemens Industry explores how troubleshooting your machine tool just got a lot faster and easier!

Call Waiting? Not For Long

Randy Pearson of Siemens Industry explains why the great news for every job shop and captive department is that communication between the machine and the plant network is faster today than ever before.

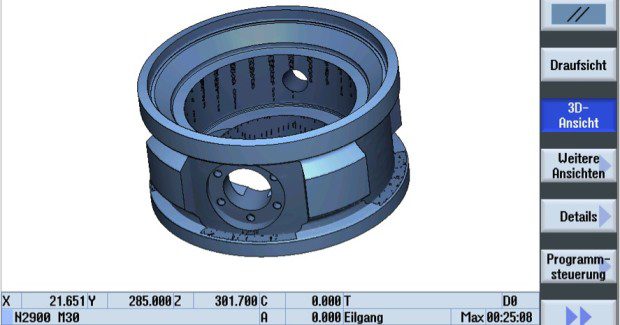

Turn-Mill or Mill-Turn… One Screen Can Say It All!

Randy Pearson of Siemens Industry explains how innovative CNC technology can now operate sophisticated multi-task machine tools with seamless transitions from mill to turn or turn to mill or both; identical look-and-feel to screens, too!

Why CNC is the Way To Go For Nearly Every Machine Shop

Randy Pearson of Siemens Industry shares some of the many reasons why CNC machines will provide your shop more profit today and more growth opportunities in the future.

Easy Operator Programming… Yes, I Said Easy!

Randy Pearson of Siemens Industry explains why less time needed for operators to program at the machine means more uptime on the machine.

Adaptive Control – And All the Ways It Can Help

The Goal is Always the Specified Dimension: Using automatic feedrate compensation, parts can be made to the same spec more often and with greater precision by the systematic CNC measurement of the drives on a milling, turning or turn-mill machine tool.

Old Habits Must Die Hard

The number of experienced machinists in the U.S. is declining, but all shops that seek operator efficiency can still achieve it through the education programs offered by machine builders and control suppliers alike.

Machine/Control Simulation Means Better Results, Every Time

Ways of the Future, Here Now: As more shops seek to maximize their machining uptime, Randy Pearson of Siemens Industry explains how the ability to simulate actual cutting conditions offline offers them many competitive advantages.

CNC: It’s All About Networking

Competitive Edge: Machine control can now provide data to every department in the shop, multiple facility companies, even outside partners, to keep everyone “in the know.”

WHY OPEN HOUSE COLLABORATIONS MEAN BUSINESS FOR YOU

Randy Pearson of Siemens Industry explains how, by working together as a team, large and small shop operations can all benefit from the collective talents of dealer and control personnel.

ENERGY EFFICIENCY PLUS FULL DATA TRACKING – A CNC CHRISTMAS PRESENT!

Randy Pearson of Siemens Industry shows how today’s CNC not only puts a greater degree of energy efficiency at your fingertip, it can also provide you more usable data for running your entire shop or machining department . . . yes, Virginia, there IS a Santa Claus!

CNC CAN MAKE YOU A MULTI-TASKING ASSET TO YOUR COMPANY

Attention Operators: Today’s advanced CNC can look and feel the same way, whether on grinders, milling machines, lathes or another machine tool, and also on press brakes, lasers, welding systems and other fabrication equipment . . . get the picture? Randy Pearson of Siemens Industry explains how and why.

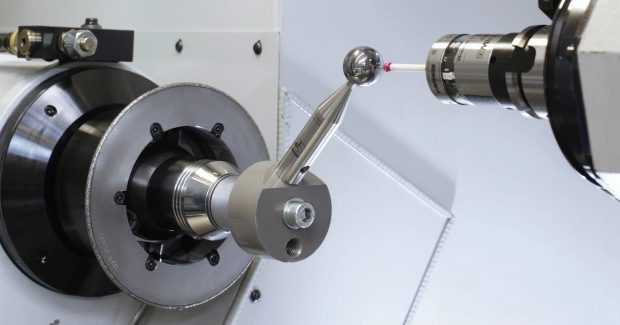

Probing Thoughts About, Well, Probing

Sophisticated CNC can do much more than just find the edge for you. Randy Pearson of Siemens Industry shows how it also improves part production and repeatability on prismatic and complex 5-axis jobs alike . . . and it keeps score!

FROM TRAINING TO PRODUCTION: NOW YOU SEE IT, NOW YOU DO IT

An offline personal computer can be used to train the operators, who then run the program on a virtual control to prove it out, all before running it on a costly machine tool . . . Randy Pearson of Siemens Industry explains how this evolution of the quasi-CAM system brings so many advantages to the shop.

HELP – HILFE – AIUTO – AYUDA . . .

IN ANY LANGUAGE, YOUR CNC CAN FIND ANSWERS

Randy Pearson of Siemens Industry explains how, with help screens, full instruction manuals and troubleshooting advice embedded in various languages at the touch of a button, today’s CNC can help machine tool operators identify and overcome most in-cycle problems quickly, so they can make more parts.

IT’S QUESTION AND ANSWER TIME

Randy Pearson of Siemens Industry responds to some of the questions he’s received over the last few months about various aspects of CNC operation.

YOUR CNC SHOULD ALWAYS SPEAK YOUR LANGUAGE

Whether in ISO or its own dedicated programming terms, Randy Pearson of Siemens Industry explains why your machine control should make your job easier, not harder.

TRUE CNC SIMULATION . . . IT’S NOT MAKE-BELIEVE BELIEVE ME

Randy Pearson of Siemens Industrial explains why, as costs become increasingly critical, every shop needs to know all it can about the true machining time.

THIS ANIMATION IS NO CARTOON

Randy Pearson of Siemens Energy & Automation explains how, through short movie sequences and onscreen prompts in plain language, CNC operators can realize a what-you-see-is-what-you-get level of operational ease.

A NEW THRESHOLD IN SURFACE FINISHING

Randy Pearson of Siemens Energy & Automation shows how unique approaches in CNC technology are making mold & die operations more productive while yielding significant improvements in surface quality.