Nick Peterson

Articles by Nick Peterson

Comparing Methods for Welding Preheat

Heating the base metal adds time and money up front, but can save time and money by minimizing potential for weld failure. Here’s how to determine the best preheating method – convection ovens, induction, open flame, or resistance heating – for your application.

5 Ways to Calculate Your Actual Welding Costs

Tracking equipment purchases, labor hours, filler metal, and consumables is obvious and relatively straightforward. If you’re like many fabricators, though, you’re probably also budgeting for expenses you shouldn’t have to incur.

Tackle Different Challenges on the Jobsite With a Welder/Generator

Wasted time and lost productivity are enemies in any welding operation, especially in harsh conditions, on large jobsites or in applications where it’s difficult for operators to get to where the work must be done. The right welder/generator system, equipped with advanced technologies, can help complete work faster while also improving quality and safety.

Five Best Practices for Multi-Material Welding in Manufacturing

To stay competitive, more shops face the challenges of welding many different types of materials. To reduce setup times and help their operators produce high-quality welds, they must move beyond basic options and invest in advanced capabilities that can have a big impact on the bottom line.

Switching Polarity in Welding Applications

When competing for time-critical jobs, saving even a few minutes with each changeover can make a significant difference and reduce operator exposure to trip and fall hazards. Investing in technology that allows welders to easily change processes with the push of a button at the weld joint can save substantial time, increase weld quality and improve operator safety.

Learn More About Electrode Extension, Stickout and Contact-Tip-to-Work Distance

Each of these terms have specific definitions, and using them interchangeably can cause confusion that puts amperage out of the specified range. Understanding the terms being used and how they are defined by AWS provides clarity that can help prevent mistakes and rework.

Reduce Wire Feed Troubleshooting with Suitcase Wire Feeder Technology

You need to minimize birdnesting, erratic wire feed speed and other problems that are causing unplanned downtime and costing you money. So what technologies should you look for when you choose a durable suitcase wire feeder for the jobsite?

Four Tips for Ensuring Proper Shielding Gas Coverage in TIG Welding

You’ve got a job that demands high weld quality and appearance. TIG welding will provide you with a greater level of control to achieve those desired results, but don’t overlook the importance of using the correct shielding gas.

Gain Advanced Capabilities with a Versatile Multiprocess Welder

The need to weld many different material types and use different welding processes is increasing on the jobsite and in the shop. The ability to weld most any material – anywhere – with one lightweight, portable welding system that delivers industrial-level output can provide significant benefits for productivity, efficiency, and profitability.

Three Ways to Address the Welder Shortage

A lack of skilled labor may mean missed deadlines, a reduced ability to compete for jobs, higher costs and lost productivity due to rework. But new technologies and welding systems being designed by welding equipment manufacturers can help fabricators address these challenges, bridge the labor gap and remain competitive by completing jobs on time with high quality.

How a Submerged Arc Welding Tractor Increases Productivity on Welding Trailer Frames and More

An operation that switches to submerged arc welding can double or even triple productivity and make more efficient use of labor time – outcomes that help justify the initial equipment investment.

Welding Game Changers for Productivity and Efficiency

Is the jobsite challenging your older equipment and costing you time and money? By switching to some of the new time-saving systems that are now available, you can save money while also improving your productivity, quality and jobsite safety.

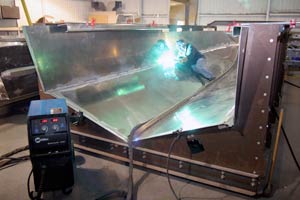

Tips for Successful Aluminum MIG Welding Repairs

With its low melting point, the presence of an oxide layer on its surface, prone to burn-through with a difficult-to-control weld pool, aluminum can be somewhat tricky. Here are some insights that will provide you with the best course of action to take for making a repair.

Augmented Reality: Finding a Better Way to Screen and Train Welding Applicants

Shops can now create a welding lab experience without a lab by using new technology that simulates various welding processes and blends real-world and computer-generated images into an augmented reality environment for a realistic welding simulation that closely resembles live arc welding – and provides them with an objective means of measuring the skills of each applicant.

How Energy Incentives on New Welding Power Sources Benefit Your Bottom Line

Considering an upgrade to your welding equipment to increase profitability and cut operating costs? Here’s how you can also take advantage of the additional benefits that energy incentives provide for an even greater impact on your bottom line.

Labor Shortage? How to Develop Welding Talent In-House

To compete in a hotbed of industrial construction and maintenance projects that require significant manpower, this fabrication shop has figured out how to meet customer demands while building a steady skilled workforce at the same time.

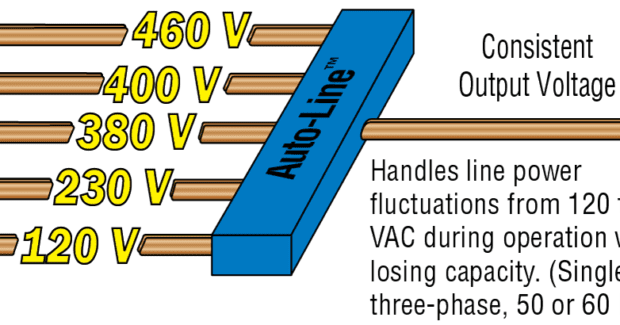

Power Management Technology Eliminates Problems Caused by Dirty Power

Dirty power can impact weld quality in many ways. Here is one way to help avoid the problems caused by dirty power and improve productivity, efficiency and weld quality.

The Right Filter Makes a Difference in Weld Fume Management

Removing the fumes from the area is only the beginning of the process. How you filter the fume is just as critical to achieve successful results.

Using Welding Intelligence Designed for Pipe Fabrication

Pipe shops now use electronic dashboards to replace pieces of paper that once traveled with spool joints across the floor and through the weld testing process.

Gaining Welding Productivity in the Field

A look at how new technologies can help contractors boost their productivity and safety when Stick and TIG welding in the field.

Dreams Can Come True

The story of Andrew Cardin, a passionate young welder who is focused on representing the U.S. at WorldSkills, represents the potential future of the welding industry.

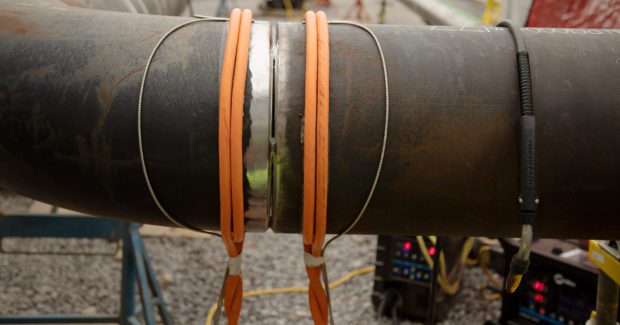

How Induction Heating Minimizes Hydrogen in the Welding Process

Low-hydrogen welding practices require attention to detail. Induction heating offers a consistent and reliable heating option that can save time and money by heating jobs in only minutes that would typically require hours to heat.

How New Technology Can Help Address Welding Industry Shortage

Utilizing tools that provide more cost-effective and efficient recruiting, screening and weld training will aid companies in finding the right welding talent and reducing training timelines, placing qualified welding operators on the production floor in a timely manner.

How Engine-Driven Welder/Generators Save Space and Fuel

A diesel engine-driven welder/generator with dual-operator capabilities is one fuel-efficient machine that provides a full range of jobs and options for multiple users on the service truck or the jobsite — all without sacrificing arc quality or productivity.

Welding with Handsaws vs. Chain Saws

Because labor costs are approximately 80 percent of the true cost of welding in the field while equipment is only about 5 percent, providing welding operators with the most productive tools is among the best ways to reduce labor costs and increase efficiency.

How Electronic Fuel Injection Technology Improves Efficiency of Engine-Driven Welding Power Sources

As contractors and welders continually look for ways to reduce welding costs and be more efficient, things as simple as engine choice can make quite a difference.

New Technology Expands Work Envelope When Using Fume Extractors

Source capture is the recommended method of fume extraction because it removes contaminated air at the source, before it reaches a welder’s breathing zone. Recent advancements in source capture technology create a much larger capture area than what’s available with existing systems and can minimize how often the welder has to move the extraction arm.

Improving Welder Safety and Comfort with New Head Protection Technologies

Recent technology advancements in welding helmets not only help to protect welders from lost-time or work-related injury, but they increase productivity by increasing comfort levels. Regardless of the type of head protection a welder chooses, it is critical to make sure that the helmet, PAPR or other such personal protective equipment (PPE) is properly suited for the welding application at hand and also provides the appropriate level of protection.

Cleaning and Preparing Aluminum Filler and Base Metals Before Welding

Dirty aluminum sets you off on the wrong foot before you ever strike an arc. Take these cleaning and prep steps for the optimal welding of aluminum.

Understanding and Lowering Weld Costs

Nick Peterson of Miller Electric explains why shops stand to reap significant benefits by better understanding and controlling whether step B in the process is truly preparation for step C, or simply compensation for the inefficiency of step A.

A Call to Action: The Need to Reform Secondary Education

Parents, schools and private industry can play a key role in better equipping our students for life after school and the full pursuit of the American dream. Nick Peterson of Miller Electric discusses the need to reform the way we think of secondary education and the path it leads to for our children and students.

Five Considerations When Purchasing a Fume Extraction System

In today’s market, highly skilled welders can choose where they want to work. An important factor for any company to recruit and retain skilled welders is to have a clean, healthy work environment. For this reason, it is critical for a company to have a reliable fume extraction system to maintain a clean and safe work environment.

Knowledge Is Power: Weld Data Monitoring

From sequencing of parts to tracking parameters, Nick Peterson of Miller Electric explores how weld data monitoring provides manufacturers with actionable information to improve welding processes, ensure quality and productivity, and help streamline welding processes.

ROOTING OUT RESISTANCE: ELIMINATING THE HIDDEN VARIABLE

Resistance is frequently characterized by random and intermittent welding issues that are difficult to repeat. But even though resistance-related problems can have many symptoms, their root cause is always the same – not enough current is flowing in the electrical circuit. Nick Petersen of Miller Electric shares some tips on how to pinpoint and root out this frustrating problem.

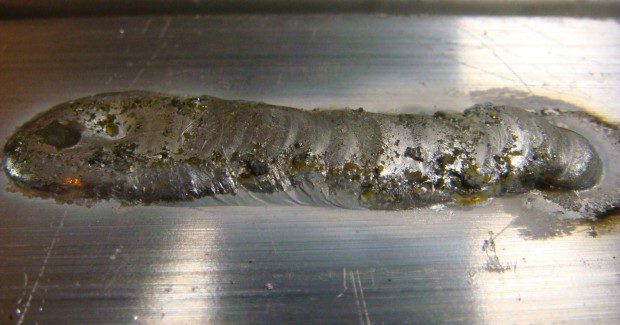

10 Common TIG Problems and Solutions

Here are some descriptions of common TIG mistakes and basic tips on how to prevent these errors from happening.

Troubleshooting the Wire Feed System

Accurately troubleshooting problems with the delivery of the welding wire to the weld pool and the current to the wire when they arise or, better yet, avoiding them before they arise, is crucial to maximizing the benefits that these processes offer.

UNDERSTANDING AND LOWERING WELD COSTS

Given that labor typically accounts for 60 percent to 85 percent of the total cost of any welding operation, fabricators stand to reap significant benefits by better understanding and controlling those costs. However, that’s often easier said than done. Nick Peterson of Miller Electric explores some practical ways to do it.

ADVANCED TECHNOLOGY ENHANCES TIG WELDING PRECISION

Advanced TIG technology provides the ability to tailor the arc specifically to your application. Nick Peterson of Miller Electric Mfg. shares some facts that will help determine the potential for advanced TIG technology in your plant.

WELDING ALUMINUM' IMPROVE YOUR PRODUCTIVITY WITH PULSED MIG

Nick Peterson of Miller Electric explains how aluminum fabricators can look toward future growth through the adoption of pulsed MIG technology.