Kim Phelan

Articles by Kim Phelan

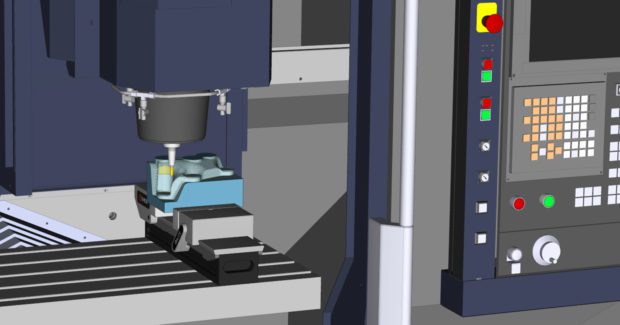

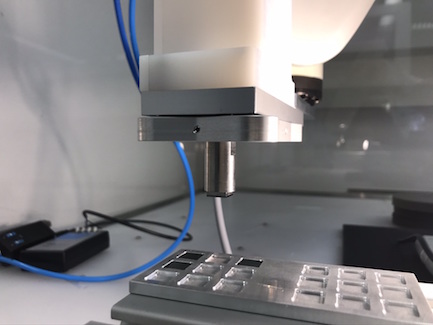

O’Neill Components Can ‘Take On That Extra Job’ With Kaast VMC

With an inch more in y-axis travel over other machines in its class, Kaast’s VF-Series vertical machining center gives one thermoform tooling maker a productivity pop in a compact footprint. Its Fanuc control proves reliable in harsh conditions.

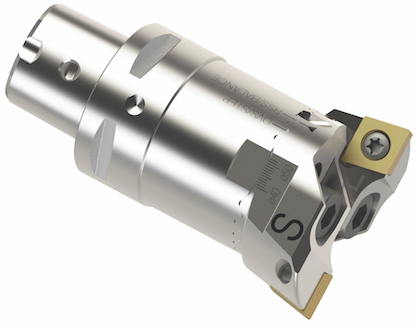

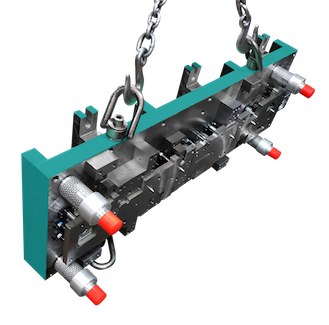

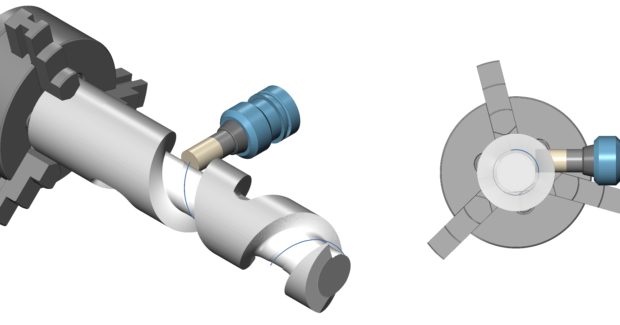

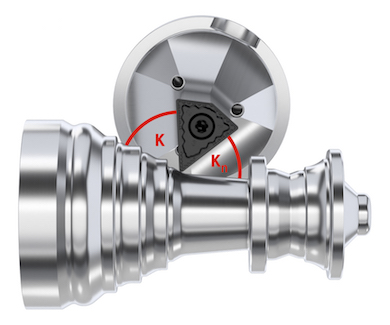

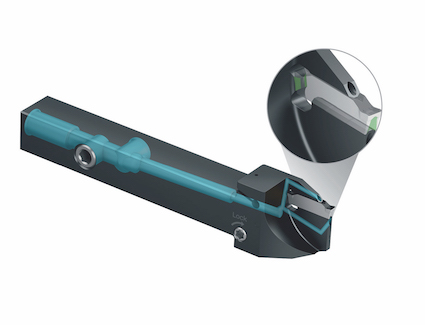

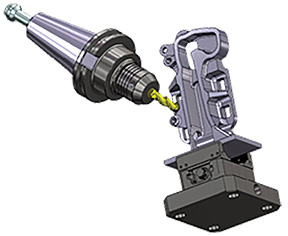

Seamless Rough and Finish Boring

BIG KAISER introduces its first BIG CAPTO rough boring tool, the Series 319 SW. Repeatability is high because its polygon taper is flush with the spindle.

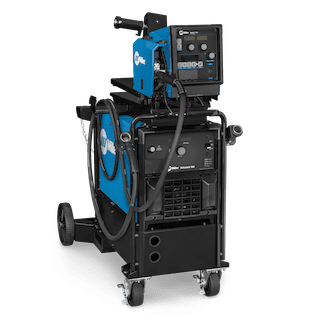

Rugged Welder Helmet with Proprietary Lens Technology

New line of RADNOR welding helmets from Airgas combines the brand’s rugged reliability and value with the performance technology of the 3M Speedglas brand. The result is a professional grade helmet that keeps welders comfortable all day.

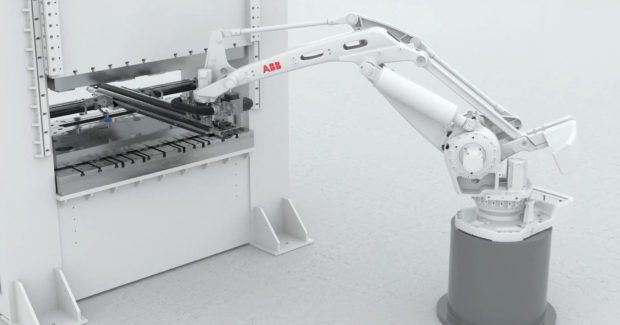

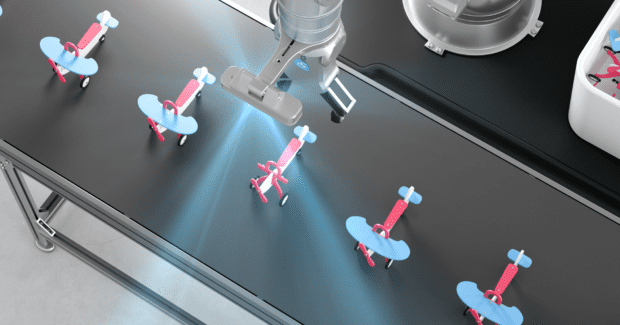

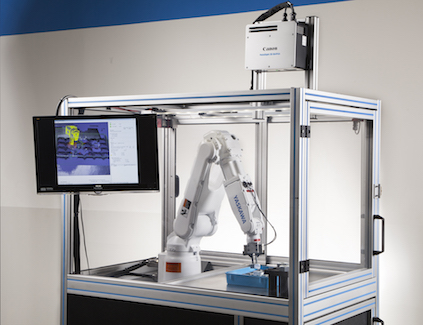

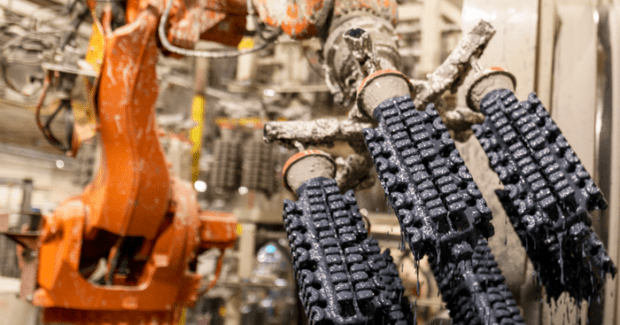

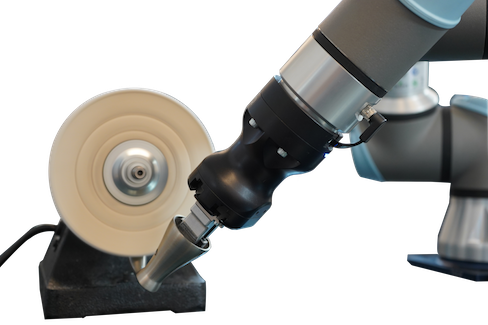

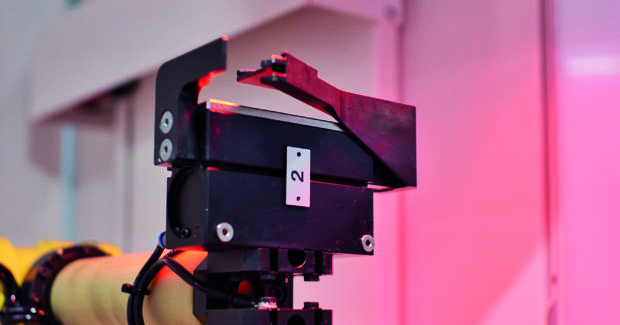

Robot Ready for Harsh and Cleanroom Applications

The IRB 1300 industrial robot from ABB features IP67, Foundry Plus 2 and cleanroom ISO 4 versions. It performs a range of tasks that includes material handling, machine tending, polishing, assembly and testing.

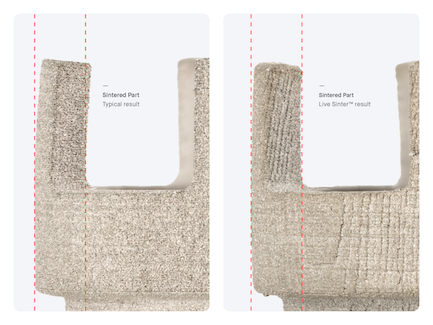

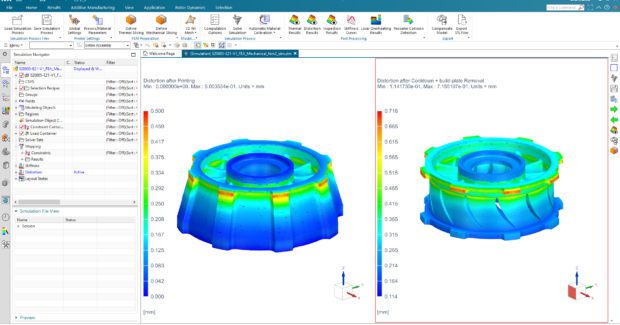

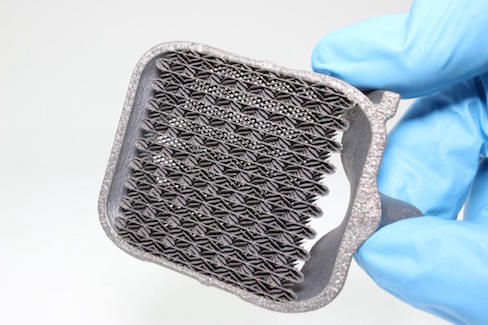

Hexagon and Authentise Partner On End-To-End AM Software Solution

The first-of-its-kind solution will integrate shop floor data with data intelligence to orchestrate consistent quality from concept to part. Statistical process control combined with machine learning and artificial intelligence methods will mitigate waste and quality issues during design while improving AM repeatability.

Digitalization Keeps Manufacturers’ Accountability Squeaky Clean

Ecoclean Connect cloud solution for parts cleaning processes ensures you’re meeting customers’ quality and traceability requirements. Defined data from the cleaning system’s control unit is encrypted and securely transmitted to the cloud.

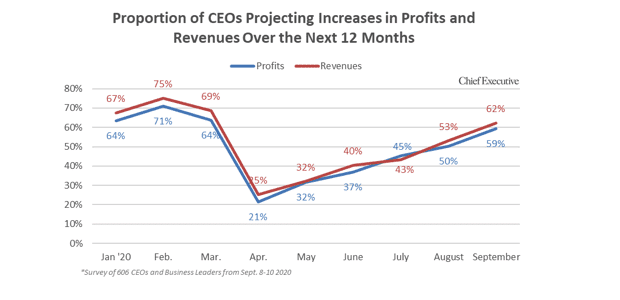

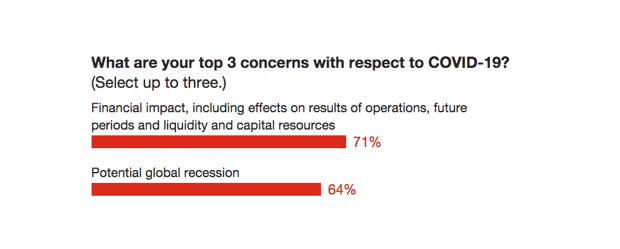

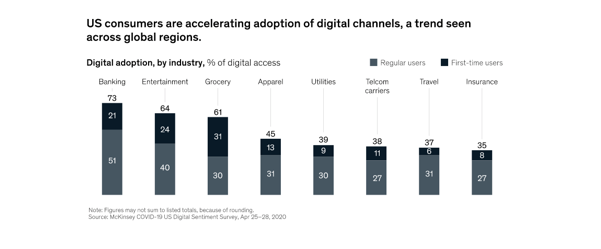

Report: Industry Accelerating Past Recovery, Toward Digital Future

Fictiv’s 2021 State of Manufacturing Report finds manufacturing leaders focused on resilience, sustainability, and speed through digital transformation. But concerns about supply chain and workforce grow.

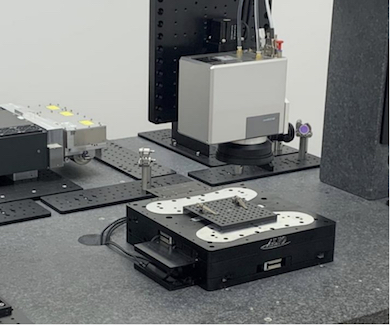

Metrology Sensors For Production Site Visualization and Productivity

Mitutoyo America’s EJ Counters and LG100 Series Linear Gages are compact, high-speed, and easy to use. Even data management is simplified with a USB interface provided for easy connection with a computer.

Spirit Levels with Adjustment and Cross-Measurement

The GN 2276 cross spirit levels and GN 2283 screw-on spirit levels from JW Winco are essential for achieving perfectly horizontal alignment of machines, mechanisms or instruments. A company conversion table helps customers identify which sensitivity is best for various applications.

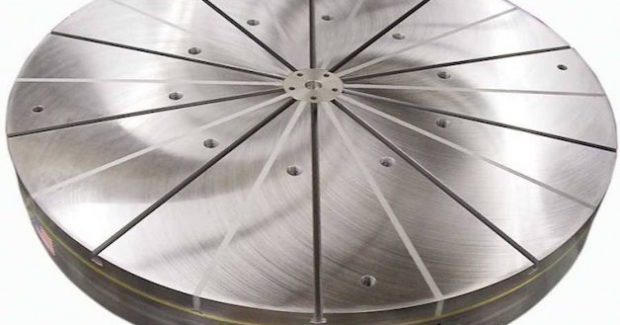

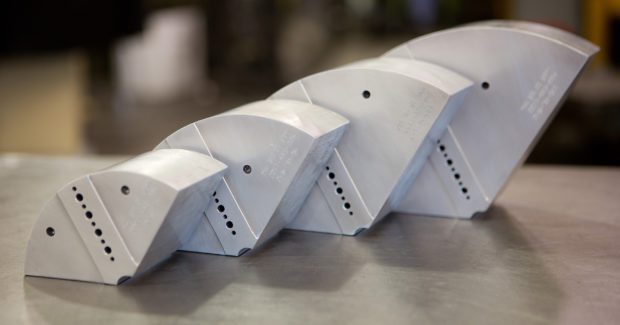

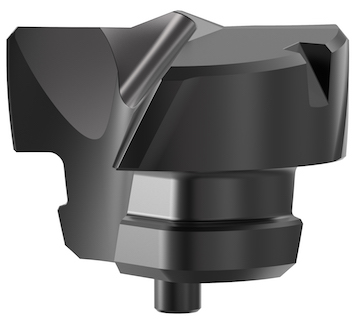

‘Drill Everything’ Insert with High-Speed Steel Geometry

Allied Machine’s T-A Pro is the machine shop’s and manufacturer’s spade drill that performs in tough conditions for about 25% less than the marketplace alternatives. Heavy equipment and aerospace part manufacturers get the hole quality, tool life and process security they demand.

Beckwood to Manufacture Two Custom Hydraulic Presses for WHK BioSystems

A 110-ton 4-post compression molding machine will be used for R&D, and a 1650-ton compression molding press will be used in the production of UHMW sheets – the demand for which is rising in medical, aerospace, and defense sectors.

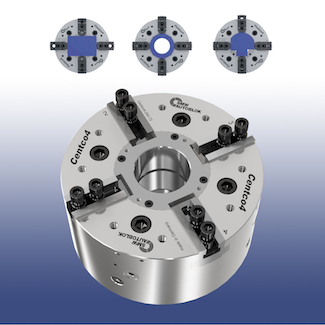

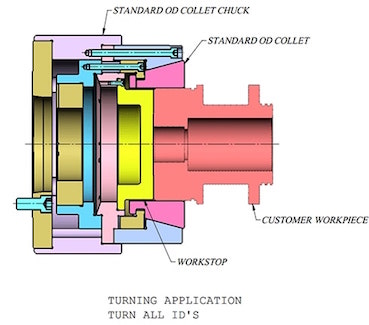

Platinum Tooling Technologies Named Tecnicrafts Distributor

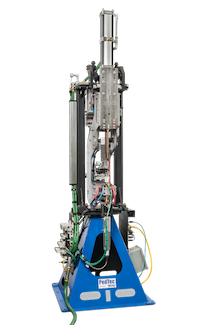

Used for Swiss Turning applications, Tecnicrafts collets, guide bushings, and bar feeder collets are available in standard and ultra-precision grades. Platinum Tooling carries and supports the full line with representatives throughout North America.

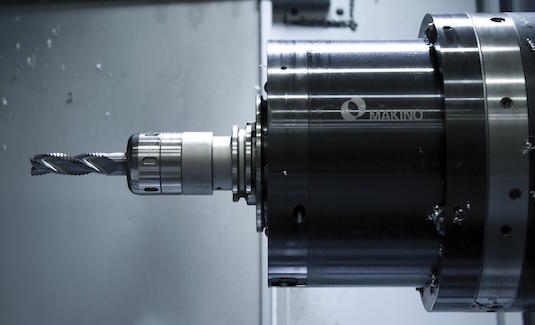

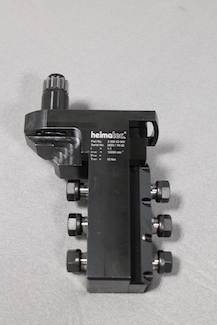

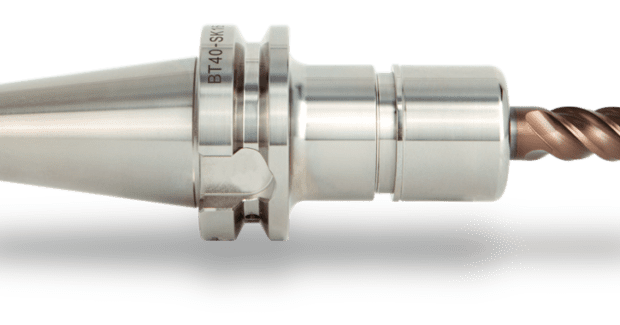

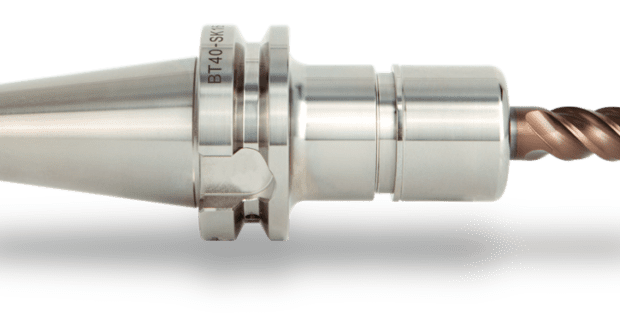

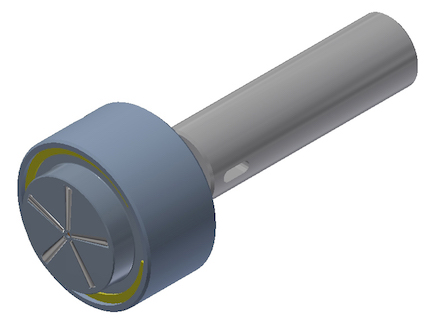

Tool Holder’s Coolant Holes Maximize Coolant Flow

The secret to better tool life is great coolant flow, and AccuKool is the secret behind Accutek’s AccuGrip Shrink Fit tool holder. Its specially designed holes keep coolant flowing to and through cutting flutes.

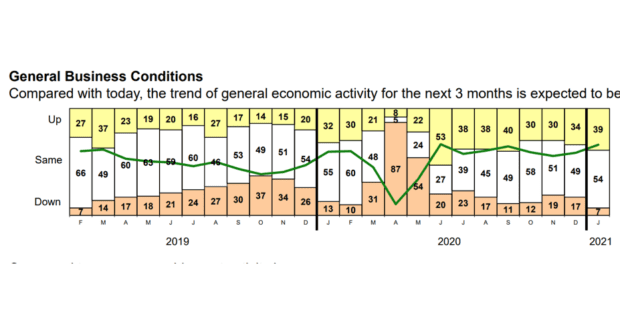

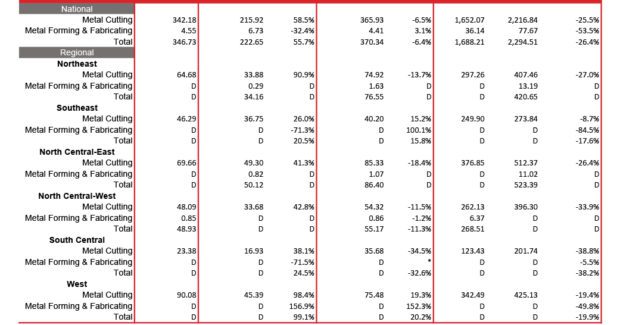

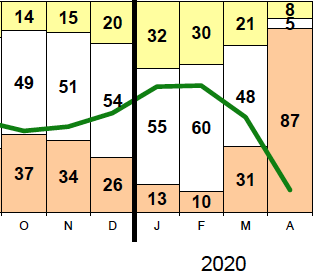

Metalformers Optimistic But Lead Times Keep Increasing

According to PMA’s April 2021 Business Conditions Report, more than half of metalforming companies predict improved economic conditions for the next three months. Finding steel continues to be a problem.

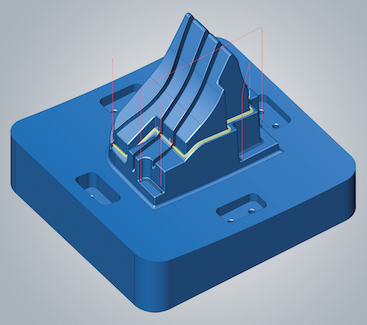

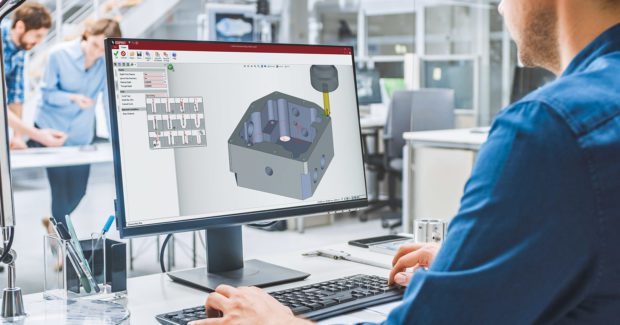

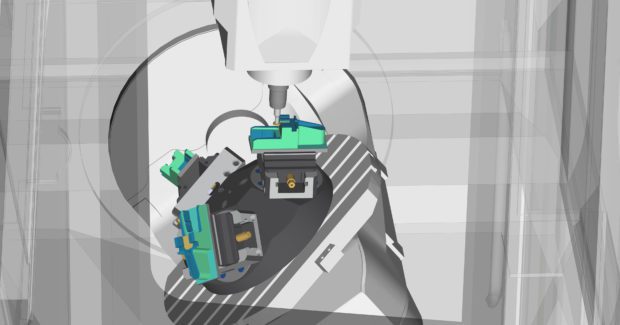

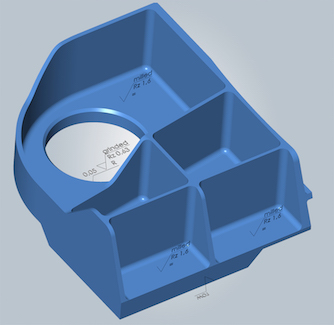

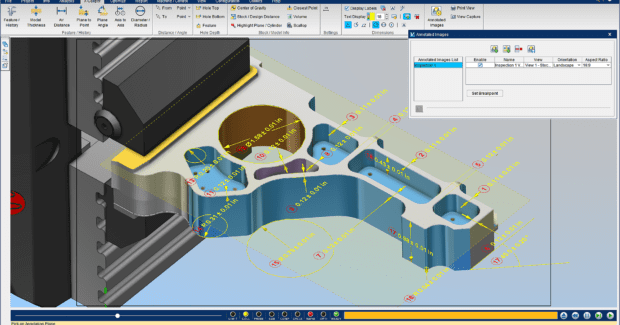

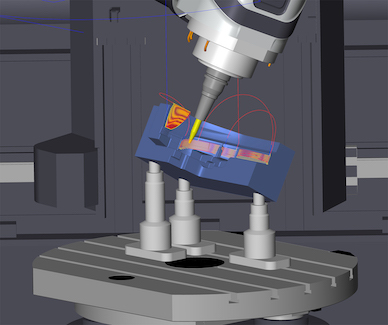

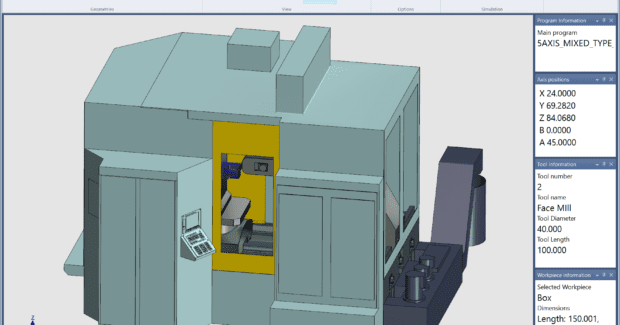

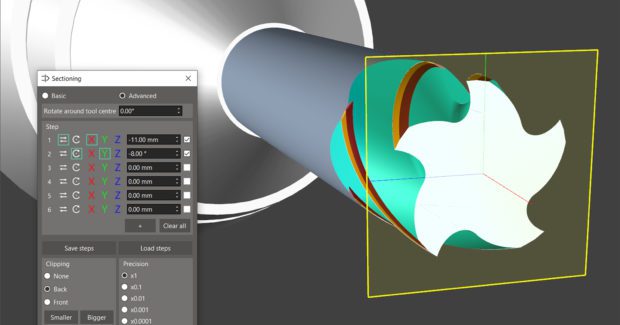

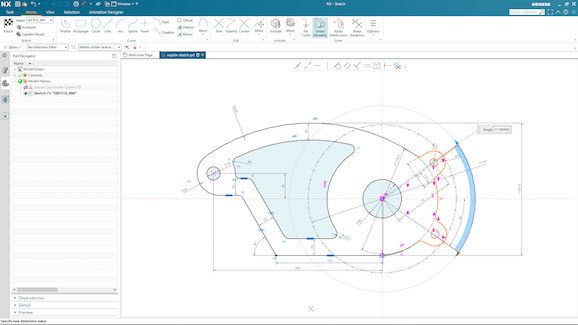

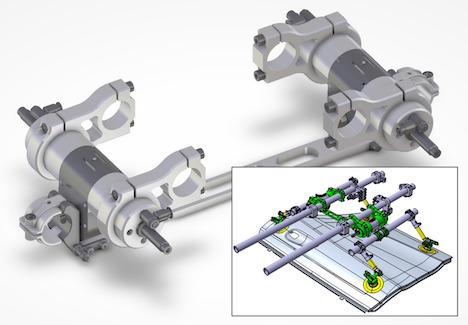

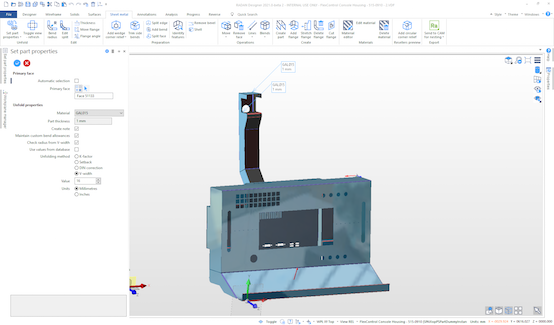

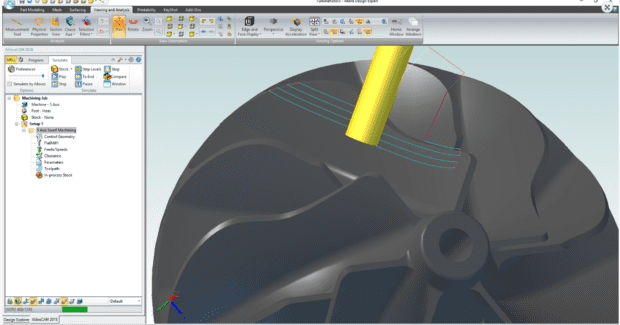

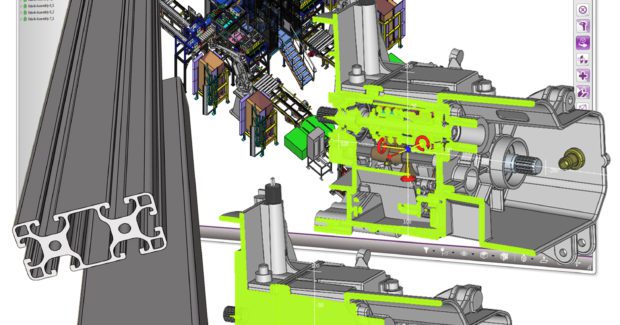

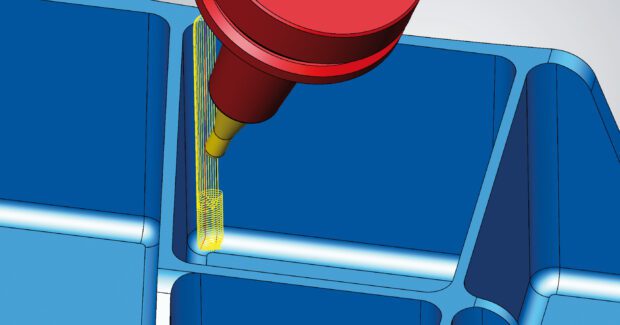

Updated 3D CAD/CAM Suite with Easy Toolpath Editing

Machining programmers using OPEN MIND’s hyperMILL 2021.1 can trim and remove sequences as needed after creating their initial toolpath. It also features a new 5-axis radial machining tool that helps users rapidly apply the most productive machining strategies.

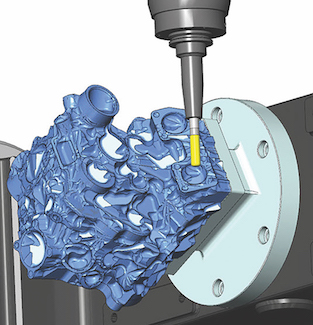

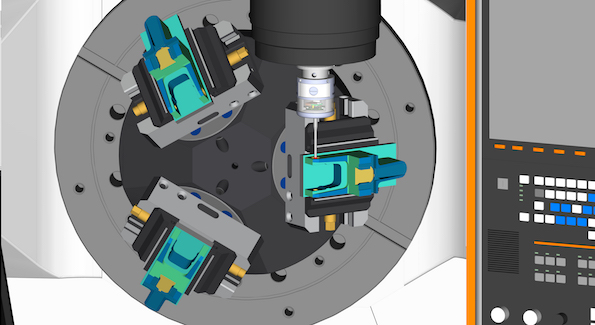

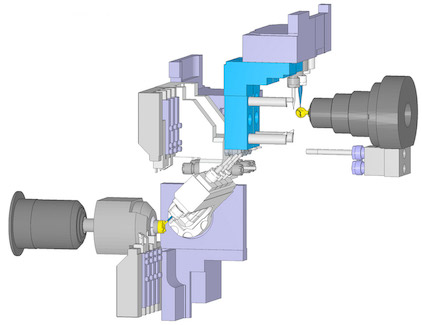

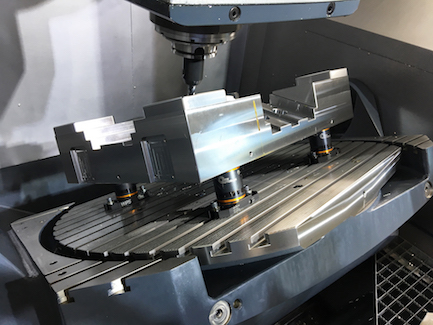

‘Upside Down’ Machining Equals Unlimited Possibilities for Part Machining

GROB Systems’ G350 5-Axis universal machining center has a special axis concept enabling the full tool length to be employed in any axis position, even with maximum part size. That “tunnel” concept enables a swiveling for largest-possible components without collision.

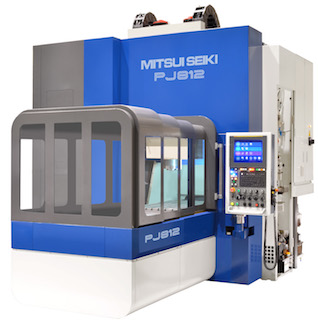

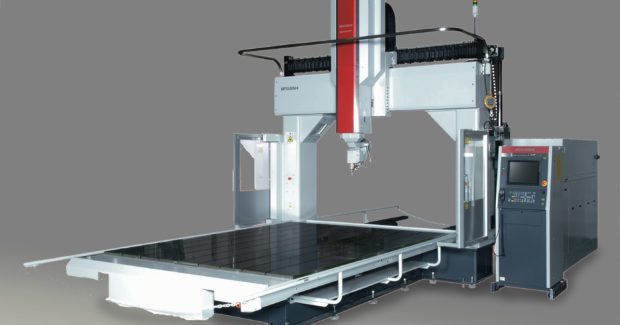

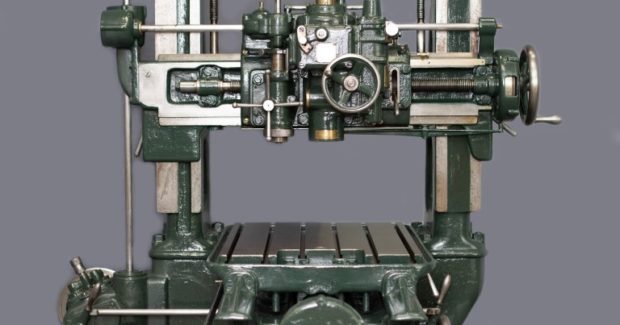

VMCs Offer Jig Milling Accuracy with Machining Center Productivity

Mitsui Seiki’s “J” series offers a positioning accuracy and repeatability of +/- 1µm. Combining machining center technology with jig borer precision in one machine, the “Jig” VMCs achieve precision boring, milling, drilling and tapping.

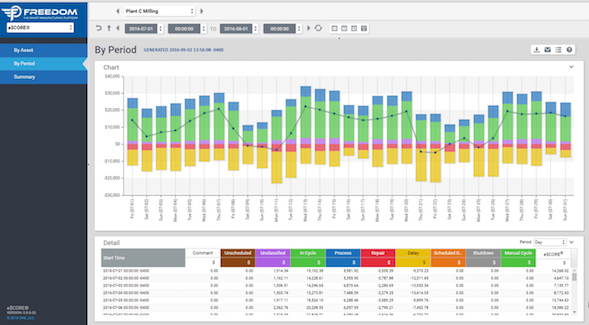

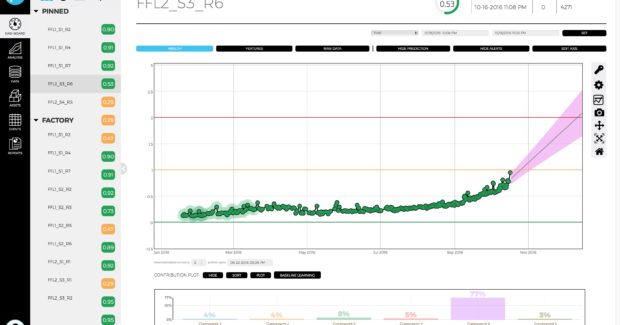

Plug-and-Play IIoT Platform Enables Digital Transformation

Attention mid-sized manufacturers: FactoryEye from Magic Software brings the digital world to you – with real-time intelligence – in an easy, affordable and flexible solution. No need to replace existing equipment or infrastructure.

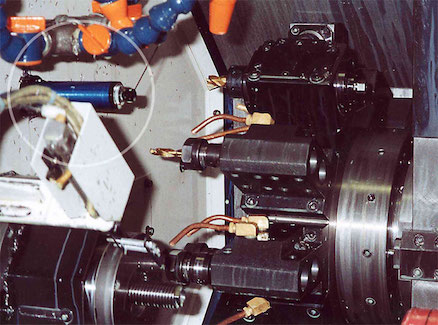

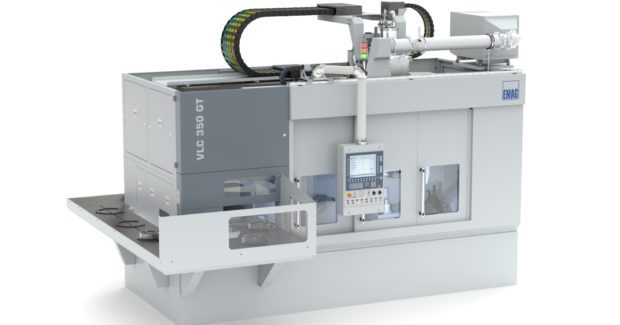

Automated Multispindle Program Creation Boosts Long-Part Machining Productivity

ESPRIT CAM’s ESPRIT TNG enables offset-aware programming of spindle transfers and bar pulls to help manufacturers drive multichannel CNC machinery. The ‘next generation’ CAM provides an exact digital replica of every facet of the machining environment.

Sandvik’s Super-Austenitic Grade, Sanicro 35, Wins Prestigious Award

“Materials Performance” magazine recognized the new Sanicro 35 alloy in its MP Corrosion Innovation of the Year Awards 2021. Designed for extremely corrosive environments and seawater applications, the alloy is ideal for heat exchangers and hydraulic and instrumentation tubing.

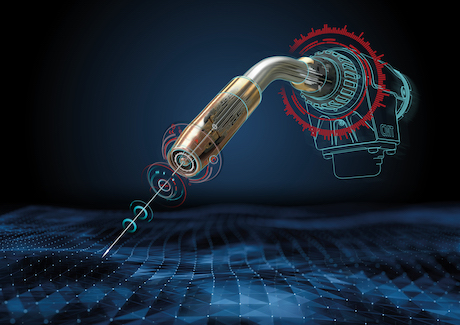

Rotary Encoders Made for Robots

Compact and lightweight, the KCI/KBI 1300 series of inductive rotary encoders from HEIDENHAIN offer contamination-resistant inductive circumferential scanning. The high-speed EnDat 2.2 interface enables more information to be communicated such as temperature or diagnostics.

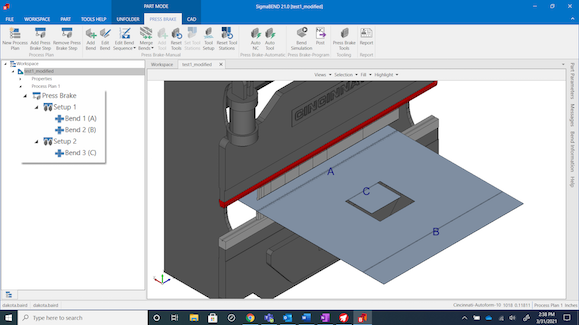

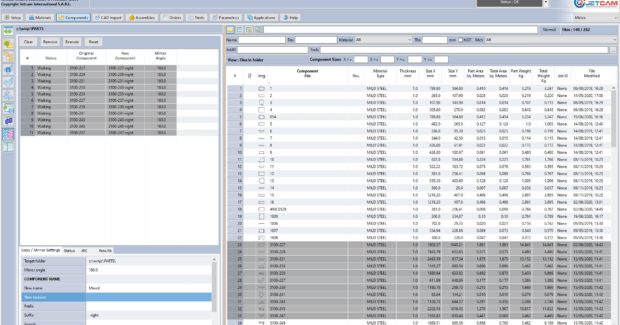

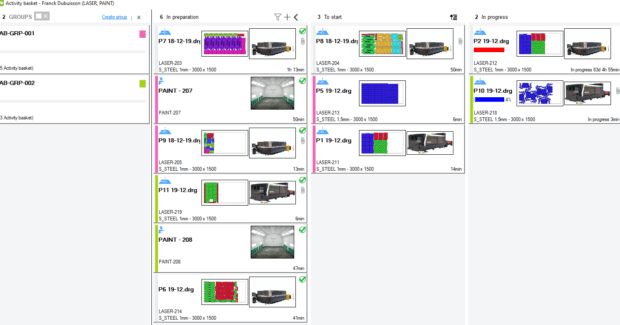

‘Connected Shop’ Provides ‘Set It and Forget It’ CAD/CAM Programming

The enhanced features of CAMBRIO’s SigmaNEST Version 21 are centered around ease of use and nesting options for every manufacturing need. The goal of the company’s Connected Shop concept is to bridge CRM, ordering, inventory, production, delivery, and accounting.

Bench Lathe for Precision Turning on Small Metal Parts

Palmgren’s versatile No. 9684504 bench engine lathe handles many turning operations in prototype, maintenance, tools, and fabrication shops. Constructed from heavy cast iron, it’s built to last.

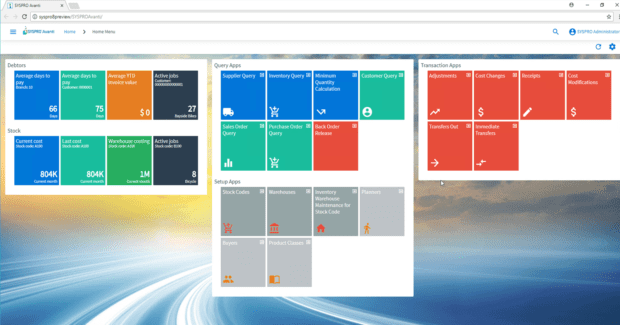

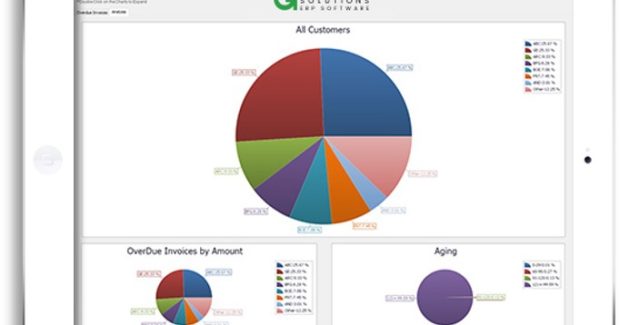

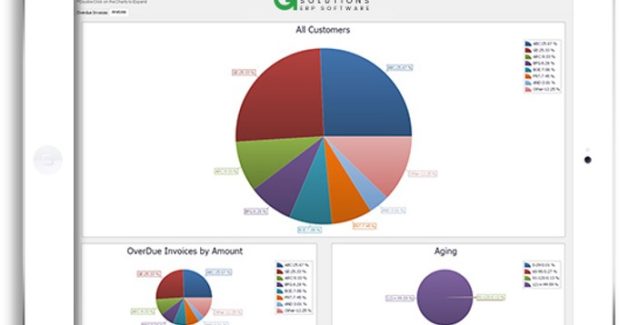

Global Shop Solutions Celebrates 10 Years of Service Team Leadership

Former Marine achieves 10-year milestone with the company, adding dependability and strength to its technical service team. Doug Johnson is the innovator behind the 20-minute FASTResponse telephone service initiative.

Material Handling Company Gives Local Soccer Team A Lift

Ireland-based Combilift kicks off its new sponsorship of the local Monaghan Ladies Gaelic football team – watch players having fun with machines and a giant soccer ball in a fun video the company launched on social media to promote the team.

The One Big Flaw in CNC Milling That’s Costing Tool Life

Early adoption of JM Performance Products’ High Torque retention knobs helped a titanium machining company overcome deficiencies at the spindle to advance its aerospace production trajectory.

Mobile Cobot Automatically Moves from Station to Station to Automatically Perform Tasks

Equipped with automatic tool-changing and multicoupling systems, Staubli’s HelMo moves itself from workstation to workstation, plugs itself in, and performs tasks without endangering its human coworkers.

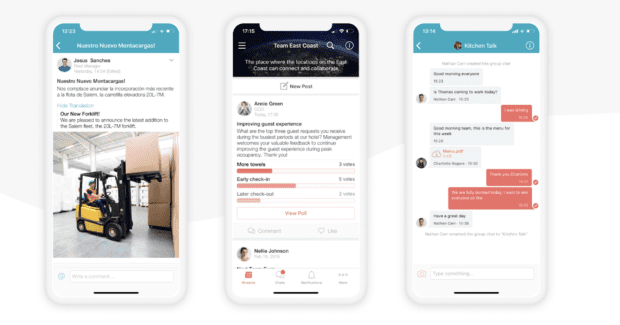

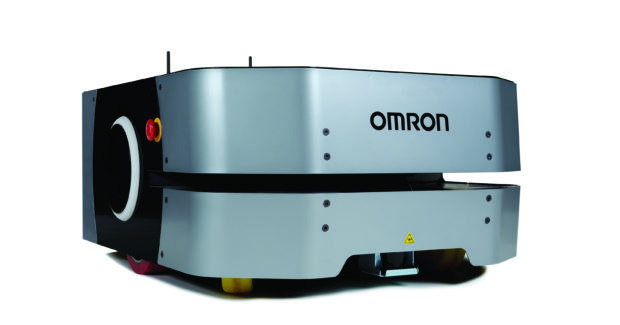

Wireless Communications Solution Lowers Material Handling Time and Errors

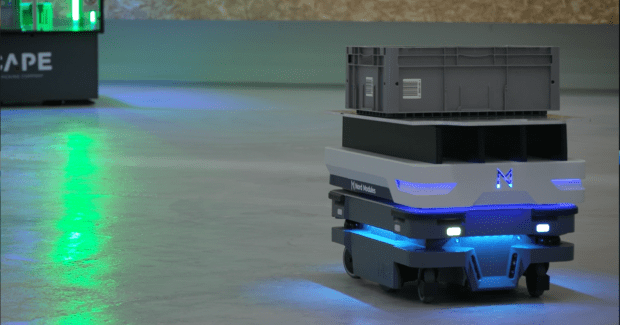

ROEQ’s replaces Wi-Fi-dependent third-party setups with a sensor-based system that automatically lifts loads delivered by an autonomous mobile robot (AMR) to the proper height for delivery to a stationary conveyor.

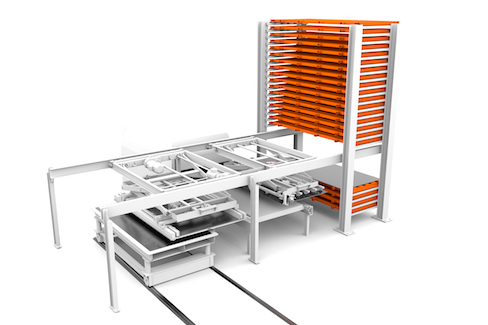

Fully Automated Material Handling with ‘One System Fits All’ Module and Cobot-Armed Gates

The QM180 top module from Nord Modules increases the utility of autonomous mobile robots (AMRs) by connecting with a cobot-powered gate to create the first fully autonomous material-handling system. It also handles half pallets, plastic boxes, carton boxes, and carts without changing top modules.

AGV/AMRs Make Moving Loads a No-Brainer

Material-handling solutions developer Kivnon expands its mobile vehicles portfolio with two autonomous mobile robot (AMR) forklifts and an automated guided vehicle (AGV) lifting platform that rotates.

Tow Tractor Moves 11,000 Pounds Automatically or Manually via a Driver

Jungheinrich’s dual-mode EZS 350a NA automated guided vehicle (AGV) provides all the benefits of an electric truck with a laser-based navigation platform that requires no floor work.

Small-Payload Cobot Provides Industrial Speed and Cobot Safety

Comau adds safety features to the Racer-5 industrial robot to come up with the dual-mode Racer-5 Cobot: a fast automation solution for supporting multiple manufacturing processes that doesn’t sacrifice precision or employee health.

New Sunrise Warranty at Trilogy Machinery

Sunrise Ironworkers’ U.S. distributor now warranties ironworkers and punching machine parts to three years and one year on labor.

Backlog of Orders Index Grows To All-Time High

The manufacturing economy continued its recovery in March, according to Institute for Supply Management’s March 2021 ‘Manufacturing ISM Report On Business.’ Backlogs are growing, as are raw materials inventories and exports and imports.

Recovery Takes Hold: February U.S. Manufacturing Technology Orders Increase Almost 18% Over January

Totaling $377.6 million, February’s latest orders represent a 32.2% increase year over year, according to AMT’s report. Oil and gas surprised with an uptick, and medical equipment’s rise likely resulted from hospitals catching up on elective procedures.

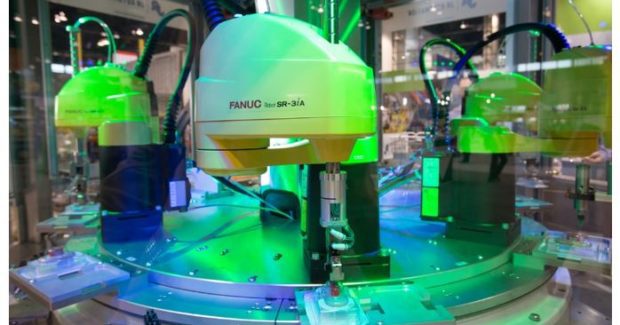

Award-Winning Design in High-Speed, 4-Axis Robots

Stäubli has set new benchmarks in dynamics, precision and cleanroom with its 4-axis line of Selective Compliance Assembly Robot Arms (SCARA) for highly sensitive environments. Judges of the 2021 Red Dot Design competition recognized its unique cylindrical working area when they gave it the “Product Design” award.

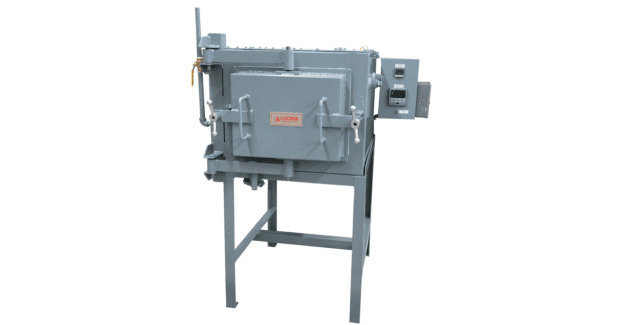

Tooling Manufacturer Adds Third Lucifer Furnace

A Connecticut-based manufacturer has installed a Lucifer 7GT-H19 for heat treating in a nitrogen-based atmosphere. The energy-efficient unit heats to 2100 F and is regulated by a Honeywell digital controller.

How to Multiply Machine Tool Efficiency with Production Automation

A new Fastems automation guide and webinar demonstrate how to overcome the six main production bottlenecks and eliminate underutilization in any shop. Fastems reveals how to make production planning and execution intelligent, automate hardware to work stably 24/7, and make processes reproducible.

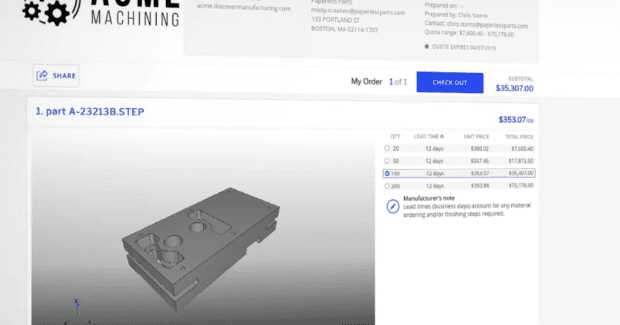

Guide Helps Level the Playing Field for U.S. Job Shops

“The Job Shop’s Guide to Trade Adjustment Assistance for Firms” is a free e-book from Paperless Parts created to make U.S. manufacturers aware of TAAF benefits that help them compete better in a market saturated with foreign imports … and walks you through the funding process.

Robot Boosts Electronics Production

KUKA’s KR 6 SCARA robot offers reach/radius options of 500 mm and 700 mm, and Z-axis stroke of 200 mm. Faster and lighter than smaller 6-axis models, it offers manufacturers ease of use while expediting production speed.

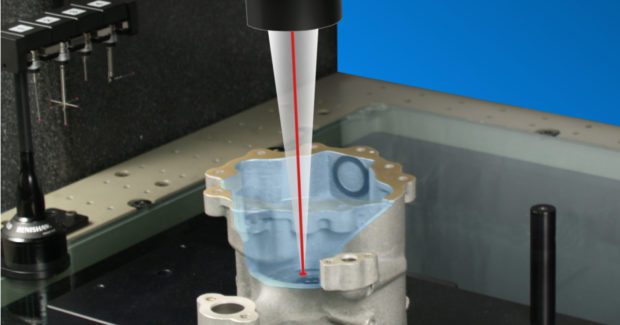

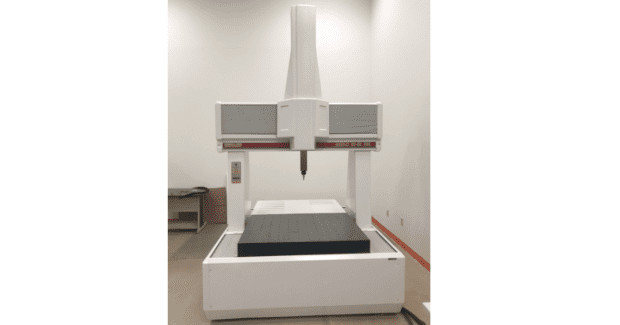

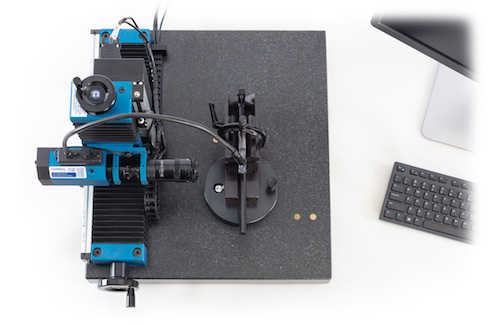

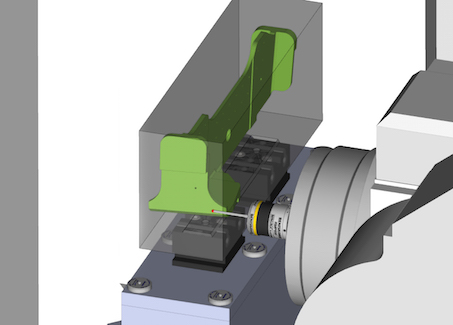

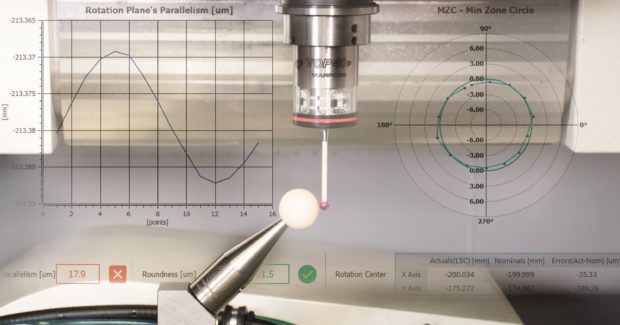

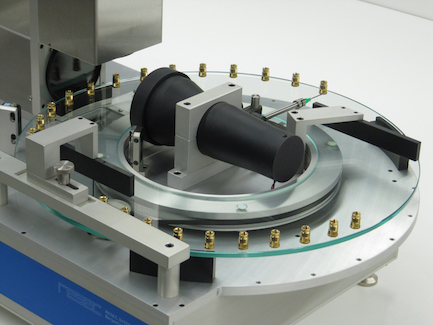

RFP Fringe Probe Increases 5-Axis Measurement System Flexibility

Renishaw’s multisensor REVO 5-axis measurement system provides highly accurate scanning, non-contact inspection and surface finish analysis at ultra-high speeds on one coordinate measuring machine (CMM).

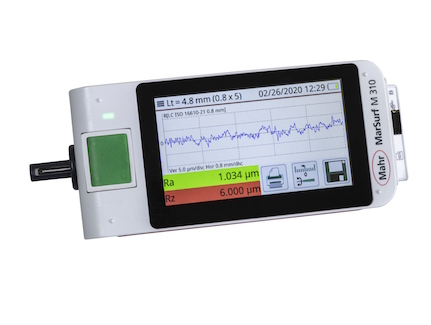

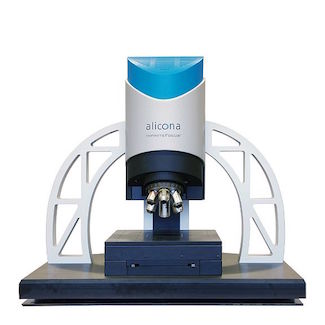

Submicron Surface Roughness Measurement

The LEXT OLS5100 laser microscope from Olympus guarantees measurement accuracy that simplify experiment workflows. The software’s several smart features minimize error with push-button scanning and analysis.

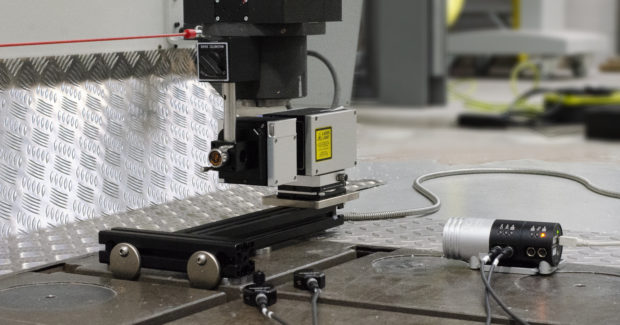

Laser Measures Wide Range of Hard-to-Reach Surfaces

Optical Gauging Products’ multisensor TeleStar Plus laser measures a wide range of materials and surface textures with extremely high accuracy. Its through-the-lens (TTL) design eliminates offset between the optical and laser sensors.

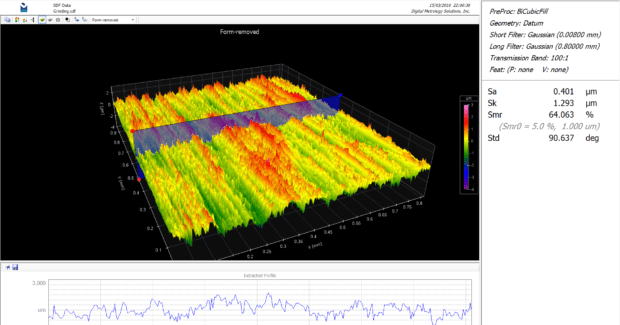

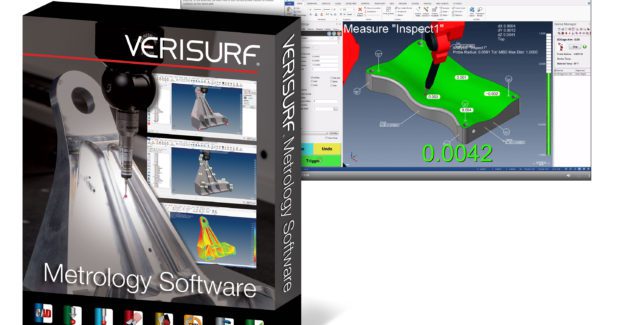

Surface Measurement for Non-Metrologists

OmniSurf3D from Digital Metrology Solutions helps users understand and communicate about surface texture without requiring a great deal of mathematical interpretation or metrology knowledge. The software provides the ability to interact with data from virtually any surface measurement instrument.

Improved Probe Provides Shop-Floor Measurements

Automated Precision’s portable vProbe performs CMM-style measurements on the shop floor and is more versatile than a portable-arm coordinate measuring machine (CMM).

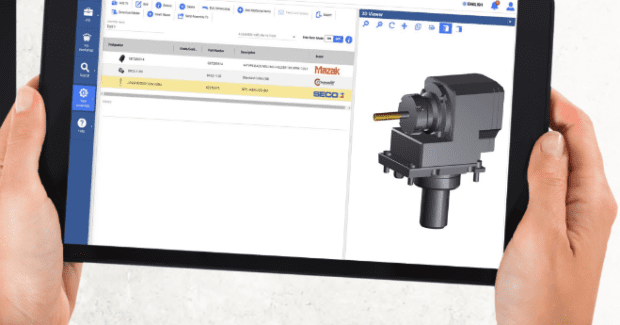

Next-Generation Square Shoulder Cutter

Seco Tools’ Turbo 16 square shoulder cutter inserts are the company’s first products with data matrix tags. The scannable codes store product and batch information, and can be read by the Seco Assistant smartphone app.

Cost-Efficient Small-Diameter, High-Feed Face Milling Cutter

Four-edged inserts help Sandvik Coromant’s CoroMill 415 face milling cutter reduce cost per component and increase productivity via a high metal removal rate. An E-M30 geometry complements M-M30 geometry assortment.

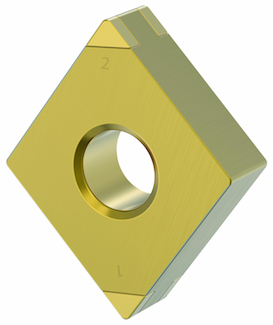

Inserts with Two CBN Tips Double Efficiency

Two tips on Lach Diamond’s CBN-Duo-power inserts are finished with type B610 or type B600 cubic boron nitride (CBN) to increase productivity when turning automotive components out of materials such as case-hardened steels and powder-metal alloys.

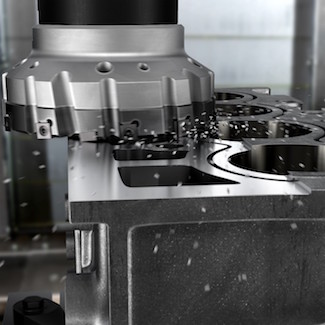

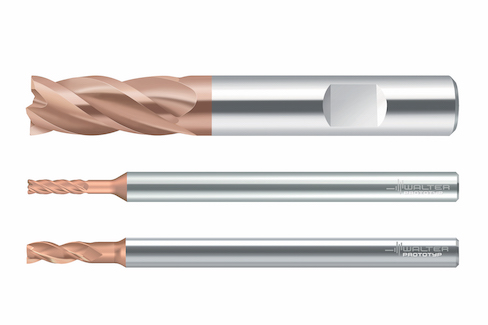

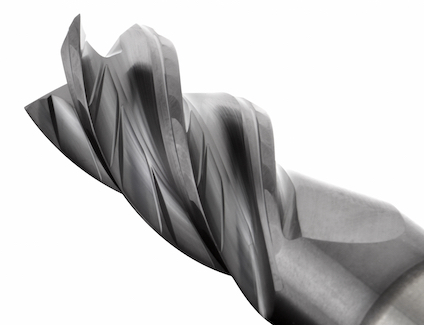

PCD Round Tools for High-Efficiency Aluminum Machining

Kennametal is leveraging its experience with polycrystalline diamond (PCD) tooling for the automotive industry to provide cost-competitive and highly productive drills, reamers, and end mills for aluminum machining.

Increase Profitability in Square Shoulder and Face Milling

Featuring square double-sided inserts with eight cutting edges, Iscar’s Neodo family of 90-degree indexable milling cutters enables face and shoulder milling in steel and cast iron as well as milling close to shoulders where there are workpiece or workholding fixture constraints.

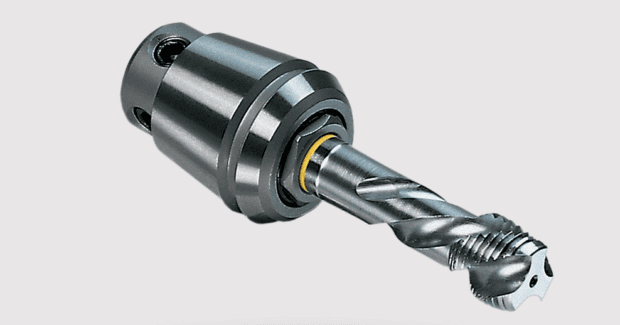

Reliably Machine Threads In Stainless and Acid-Resistant Steels

The Hoffmann Group’s Garant Master Tap INOX taps are available in inch sizes as well as metric threads with a longer design for increased reach and for all thread standards.

Best of Both Worlds: Carbide’s Strength and Ceramic’s Speed

The phase-hardened ceramic substrate on Greenleaf’s XSYTIN-360 end mills provides ultra-high strength and wear resistance at twice the feed rate of carbide end mills when slotting, pocketing, and profiling high-temperature alloys and other difficult-to-machine materials.

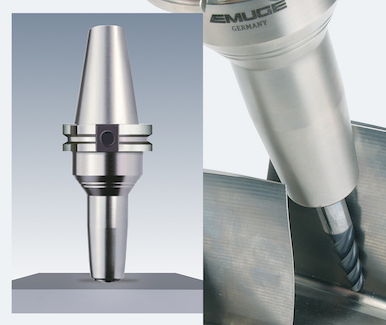

New Tooling Cuts Shop’s Machining Costs By Almost Two-Thirds

A Tier 2 automotive supplier wasn’t getting the most possible out of its vertical machining center until the shop tooled up with the TOP-Cut VAR end mill and FPC milling/drilling chuck from Emuge.

Economical Face Milling Of Stainless Steel

Featuring the greatest number of cutting edges available for positive inserts, Dormer Pramet’s S450E double-positive 45-degree milling cutter allows the same cutter body to be used with octagonal inserts for face milling and round inserts for face/copy milling.

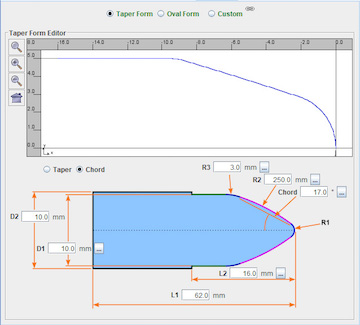

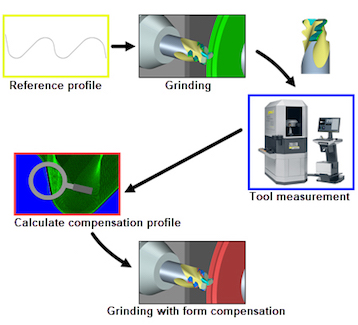

Expand Machining Capability with Updated Tool-Manufacturing Software

In addition to a user-friendly design wizard, ANCA’s ToolRoom enables cutting tool manufacturers to expand into new markets with barrel shape ballnose (BSB) and large-radii double corner radius (DCR) endmill tool types that increase productivity.

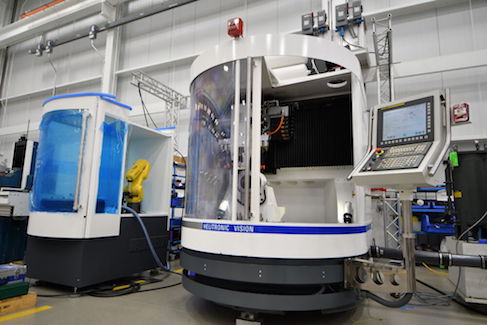

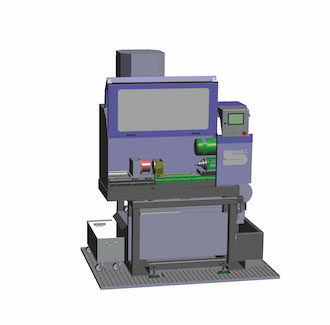

Grinder Enables Lights-Out Production of Extremely Tight-Tolerance Machining Tools

Vollmer’s 5-axis VGrind 340S machines carbide drills and milling cutters with diameters from 0.3 mm to 12.7 mm, sizes increasingly in demand in the automotive, electronics and medical sectors. Automation options enable unattended production around the clock.

Add the Latest Controls to Older-Model Grinding Machines

Owners who rebuild their Walter Helitronic Power machine can get the same speed, functionality, and ease of use as new models without the expense of buying a new machine with standard automation features.

Cylindrical Grinders For Precise Packaging Components

United Grinding’s Studer S41 (universal) and S131R (radius internal) are designed to produce large, heavy canning and die-forming components from the extremely hard metals commonly used in the packaging industry.

Updated 5-Axis Tool Grinder

Star Cutter’s NXT runs the latest NUM tool-grinding software, provides automated marking, accommodates denser pallet arrays, and produces multiple profiles for tools up to 10 inches in diameter in a single run.

Heavy-Duty Bench Grinders

Palmgren claims its line of heavy-duty bench grinders provides four to seven times longer duty cycle under load and eight times less speed degradation than competing products. Wheel diameters: 6 to 12 inches.

Thread Grinder Produces Workpieces More Than 6 Feet Long

Automatic phase, notch-position and effective-diameter adjusters along with automatic wheel in-feed position adjustment ensure Mitsui Seiki’s GSH 200A thread grinder delivers consistently repeatable precision.

High-Speed, High-Precision Surface Grinder

Featuring a longitudinal feed rate of 975 inches/minute and vertical feed of 17 inches/minute, Kaast’s F-Grind AH Series is equally capable of achieving a high-quality surface finish or critical dimensions on cutting and threading tools, punches and gauges.

Form Grinding Ball Valves Raises Output and Reduces Cost

Glebar’s PG-9DHD centerless form grinder accepts a 10-inch-wide work wheel to produce multiple parts per cycle in a single infeed motion. It shapes spherical and cylindrical components 0.050 to 4 inches in diameter.

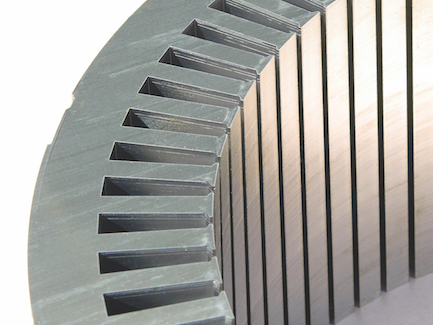

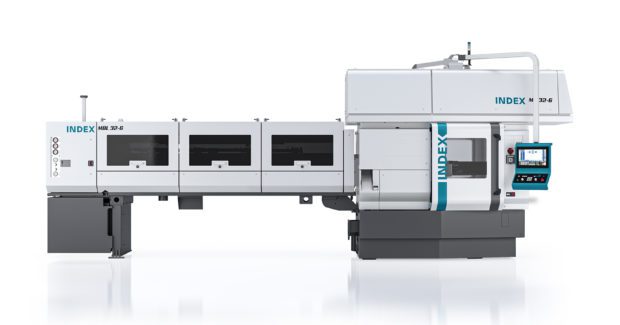

Perform Two Gear-Machining Processes in One Clamping

Both a grinding and a turning machine, EMAG’s VLC 350 GT speeds transmission component production by enabling multiple machining processes of chucked parts in a single clamping operation.

Rotary Table Surface Grinder Cuts Replacement Tooling Costs Almost in Half

Get more life out of virtually any brand of tooling for turret presses, ironworkers, and rooftop punches as well as progressive and other dies with DCM Tech’s turnkey punch and die grinder (PDG) with 18-inch rotary table.

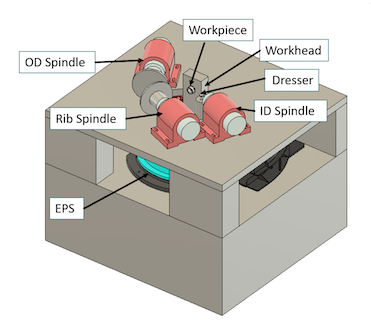

Grinding Method Eliminates Need for Multiple Machine Tools

Almost any operation that requires a combination of high accuracy and high force can be improved with the Eccentric Positioning System (EPS) from Coventry Associates. The grinder uses three circular rotary tables on top of each other instead of linear slide systems.

Creep Feed Grinder Makes Light Work of Large, Heavy Components

United Grinding’s Blohm Profimat XT relies on a 80 hp spindle and 20-inch-diameter grinding wheels to fashion workpieces weighing almost 1,800 pounds. Control interface customized to visualize machine monitoring data.

Standalone Gauging Software Handles 1,000 Different Part Programs

Marposs’ Merlin Plus isn’t just for Merlin hardware anymore – the industrial production analysis and control is available for PCs running Windows 7 or 10. Equipped for 250 different measurements, it also comes with a free add-on to create graphical pages.

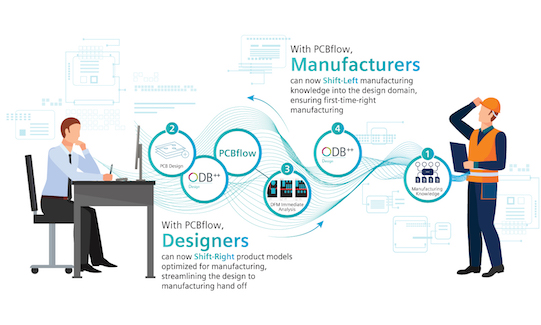

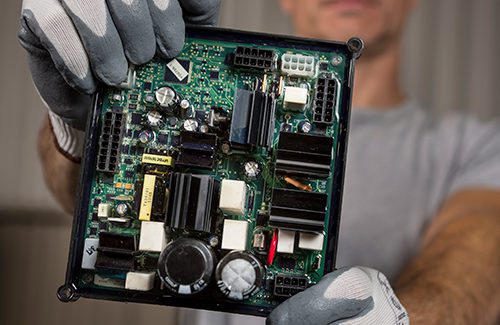

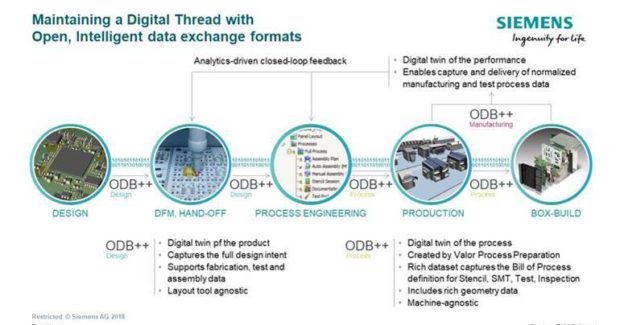

Cloud-Based ‘Ultimate Product Design Tool’ Facilitates Collaboration

Siemens’ PCBflow helps accelerate design-to-manufacturing handoff for printed circuit boards. The initial release includes instant Design for Manufacturability analysis.

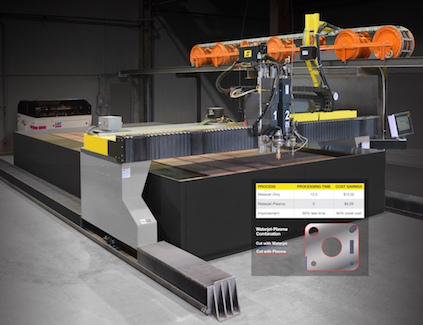

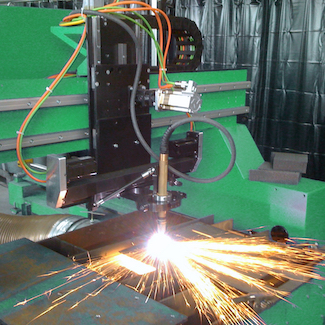

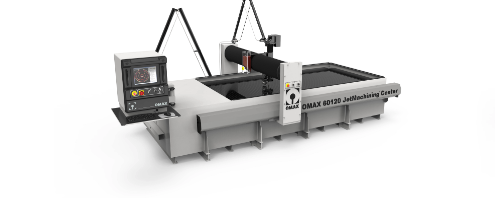

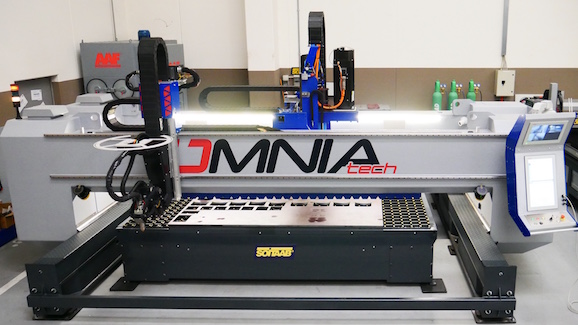

30th Anniversary Pricing on AAG Brands

AAG Tailored Cutting Solutions – AXYZ, WARDJet and CNCShop – is celebrating 30 years in business, and customers get the gifts. It all began in 1991 when two friends started doing router repair work.

AWS Helps Industry Recruit Next Generation

The American Welding Society launches “Take the Torch” initiative to attract millennials and Gen Z into the welding community.

Mount This Robot Controller Your Way

Designed to mount in four different ways, KUKA’s KR C5 micro is about 200% smaller than full-sized controllers, but storage capacity isn’t sacrificed. It’s equipped with the latest KUKA System Software – users can easily migrate in their programs from the previous version.

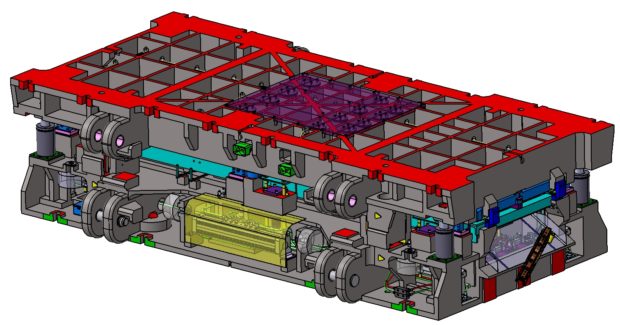

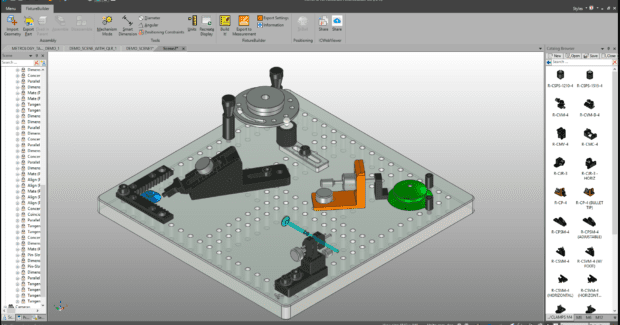

Simulation Software Optimizes Press Productivity

Tooling Tech Group can analyze incoming part files, fix clash and clearance violations, identify tool design changes, and make adjustments to achieve the highest strokes per minute (SPM) without going through trial and error on the stamping floor. This applies to servo, mechanical and hydraulic presses regardless of manufacturer.

Device Protects Ball Bearing Retainer Cages

Throw out your rubber bands and twist-wire! Superior Die Set’s Cage Saver retracts ball bearing retainer cages during die-handling and maintenance and protects the assembly from water and detergent during pressure washing.

Efficiency-Driven Turret Punch Press

Murata Machinery’s Motorum M2044TS turret punch press uses a servo-electric punch drive system that incorporates the latest ram drive design. Large turret provides more stations for greater flexibility and increased productivity, and its smaller table is sized to accommodate limited floor space.

Combination Machine Provides a One-Two Punch. Literally

LVD’s Strippit PL provides a fiber laser cutter and punch press in one machine. The combination enhances efficiency by reducing production time and material handling, and lowers cost per part in both small lot sizes and high-volume runs.

Automatic Ball Cage Punching Machine Increases Output By More Than 40%

Powered by a servo drive instead of a flywheel, Karl Klink’s RT-HLKK1000 ball cage punching machine improves cut quality by increasing cutting speed. Two die stations and streamlined retooling process also help shorten cycle times from 10 to 7 seconds.

Eliminate Secondary Bending Operations with Multifunctional Machine

Offering 22 and 30 tons of force, the Q5 CNC is the largest of Haco’s three turret punching machines. Automatic tool changer that rotates at a speed of 122 milliseconds eliminates wear common to traditional turret punching machines.

Redesigned Punching Machine is Quieter Than Ever

Fabricators can easily integrate Boschert’s Compact EVO CNC punching machine into their networks via the machine’s interface. Operators can program complex CAD parts with the company’s BG Cut software.

12,000-Joule Capacitive Discharge Welder

Weld Systems Integrators’ next generation of capacitive discharge (CD) welders monitors force in real time to ensure consistent-quality results. Throat depth provides room for automation options such as end effectors and fastener feeders.

Machine-Monitored and -Controlled Linear Friction Welders

Taylor-Winfield Technologies’ linear friction welders use solid-state bond welding to join parts of the same or different material in various geometries. Operators can adjust frequency and amplitude during the process.

Heavy-Duty Rocker Arm Seam Welders

Georgia-based Standard Resistance Welder products include Models RS1 and RS2. Offering a wide range of standard and optional features, the heavy-duty rocker arm seam welders are built around welded steel bases.

Resistance Welders for Any Lot and Part Size

Financing, lease, rental, and recondition-to-new programs are available for all Seedorff ACME rocker arm, pedestal, bench, press-type, seam, butt-and-tee and multispot resistance welders. Automation options available.

Ultrasonic Metal Spot Welder Delivers Repeatable, High-Quality Results

The actuator’s dual linear bearings and a digital load cell enable Emerson Industrial Automation’s Branson GMX-20MA ultrasonic spot welder to deliver consistent quality from weld to weld by maintaining energy levels.

A Different Type of Bond – Hold the Filler Metal, Please

Solid state and resistance welding use pressure and/or electric current to fuse dissimilar metals, nonferrous metals, and composites without generating defects, like gas porosity and hot cracking, seen in fusion welding. Think things like bus bars and switches in automotive electric systems and appliances and nuts and fittings on various parts.

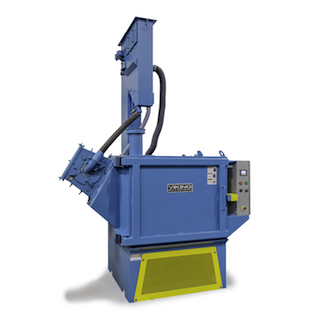

48-Inch-Diameter Table Blaster

Viking Blast & Wash Systems adds the model 48T shot blaster to its industrial line of table blasters. Airless blast cleaning is accomplished via one 15-horsepower VMax center-fed blast wheel.

Modified Alcohol Ensures Process Stability In Metal Cleaning Applications

Safechem’s Dualene 1601 S is the first pre-stabilized, pure and virgin-grade modified alcohol developed for a wide range of metal cleaning applications. Results are comparable to Dow Chemical’s Dowclene 1601.

Multimetal-Safe Formula Cleans and Protects

Kyzen’s Metalnox M6314CP cleaner and corrosion inhibitor can be used in virtually any industrial cleaning system and process to remove manufacturing oils from machined and fabricated parts.

Four Spray Systems for Parts Cleaning

MAFAC machines from Jayco Cleaning Technologies can be programmed to rotate the basket with or against the spraying frame. Built-in oil separators and demisters eliminate the need for an external device and exhaust ducting.

Vacuum Washers for Parts Manufactured in Oil- or Water-Based Cutting Fluids

Gosiger’s Kleen Power (KP) KP.HMA machines remove contaminants from hard-to-reach, small-diameter tapped holes, blind holes and deep counter bores. The energy-efficient vacuum washers increase productivity by continually separating, cleaning, and reusing solvent.

Recyclable Packaging Film Prevents Corrosion and Discoloration

In multiple industry and OEM tests, Daubert Cromwell’s ClearPak 5000 earned the highest rating as a vapor corrosion inhibitor (VCI) for protecting aluminum, steel, and copper parts during storage and shipping.

One Product Protects Electronic Components from Two Types of Damage

Available as a bag or film, Cortec’s EcoSonic VpCI-125 guards against corrosion as well as damage from electrostatic discharge (ESD). Bonus: The vapor phase corrosion inhibitor (VpCI) product is recyclable.

Energy-Efficient Wash-Rinse-and-Dry Parts Cleaner

By providing full immersion as well as spray cleaning, Ransohoff’s LeanDrum CF for high-volume cleaning and cold forming applications eliminates the heat loss common in traditional spray systems and lowers chemical consumption.

One Solution Cleans Multiple Metals

BHC’s one-product AquaVantage 3800 GD doesn’t contain any regulated ingredients. The mild formulation is safe and effective for cleaning steel, aluminum, and titanium parts for a wide range of manufacturing sectors.

Safe All-in-One Solvent-Based Parts Cleaners

Solvent-based vacuum degreasing is good for the environment, employees, and the bottom line. One machine cleans and dries parts by “sucking out” any remaining vapors before an operator touches them. Many systems also filter lubricant for reuse.

Organic, Biobased Rust Remover

Orange peel – who knew? Nontoxic and nonflammable, EcoAir 422 from Cortec sprays on and rinses off with water. Technology that’s friendly to the environment, even the packaging is designed to protect nature while EcoAir protects metals from corrosion.

High-Volume Parts Washer Works Fast in a Small Space

The Cell-U-Clean RTL washer is a stainless steel, energy-efficient blowoff unit with optional liquid stage for rinse or rust protection applications, as well as optional robotic loading. Cleaning parts up to 40 pounds, the RTL really hustles at 120 parts per hour.

Same-Day Rental on Pipe Welding End Preparation Tools

Esco’s Rental Tools Program puts the full line of MILLHOG I.D., COHOG O.D., and Universal Air Powered Saw and track systems into users’ hands anywhere in the U.S. The tools bevel any degree on all types of alloys in diameters up to 36 inches.

‘One-Button’ Advanced Rockwell Hardness Tester

Buehler’s Wilson RH2150 is easy to program and offers an intuitive software interface with Buehler’s DiaMet hardness testing software. Use the external footswitch with the actuator-mounted clamping device to clamp and activate either manual or automatic start, as well as to release manually or automatically after test.

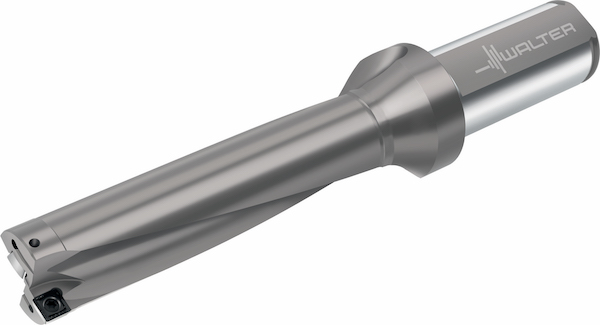

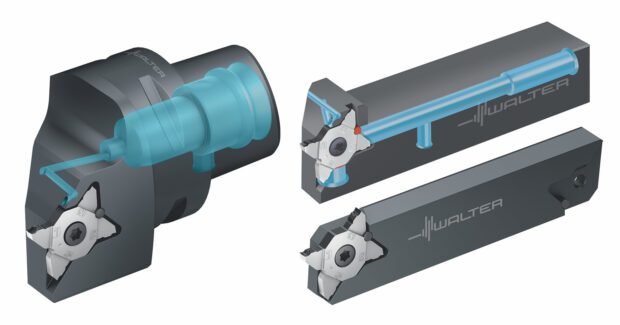

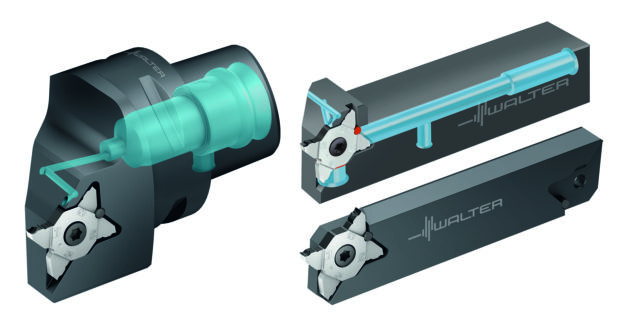

Walter Extends Advance Tap Line with Larger Sizes

Universal TC117 blind-hole and TC217 thru-hole taps from Walter just got more versatile with oversized extensions. Able to handle material ranging from steel and stainless to cast iron and non-ferrous materials, both taps use HSS-E substrate with cobalt enrichment, which enhances durability.

New GARR TOOL Tool Library Available for Mastercam

CNC Software’s user base of 280,000 can import the full line of GARR cutting tools directly into toolpath operations. The native, Mastercam 3D tool database is fully compatible with Mastercam 2019, 2020, 2021 versions.

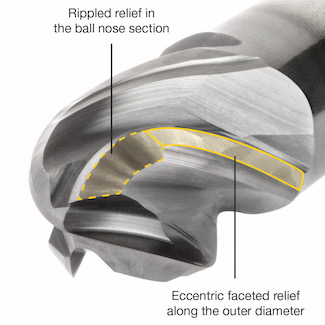

Maximum 3D Milling Metal Removal

Designed for high productivity and tool life, Kennametal’s versatile HARVI I TE ball nose end mill features a proprietary, rippled relief on the ball nose section that enables high feeds and speed. It also provides exceptional edge strength, geometric accuracy, and lower cutting forces.

Dynabrade Inc. Names New President

The company’s CFO, Michael Buffamonti, steps into his new role on April 1. He’s been a valuable financial leader at Dynabrade who also worked closely with the company’s founder.

Next Generation High-Performance Drill for Cast Iron Applications

Thanks to its low-thrust drill point design, Kennametal’s HPR solid carbide drill can be used in imperfect clamping conditions or on thin-walled applications. It also features a patented corner radius that improves tool life and provides excellent hole quality.

Digital-Ready Boring Tools Simplify Precision Adjustment

Frustrated by losing count of how far the adjustment screw was turned when dialing in a tight bore? Kennametal’s eBore Fine Boring System keeps track of boring bar movement for you. End result: less scrap, less downtime, and faster setups.

Shredder Economics in Recycling and Size Reduction

Not only do shredders reduce labor and the safety risks of manually cutting scrap products in metal recycling – they also cut energy expense and maintenance costs. But how do you match the right shredder to the application? Amos Mfg. offers help.

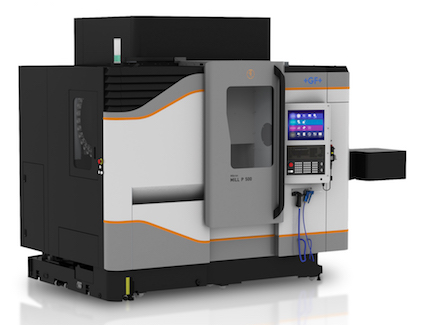

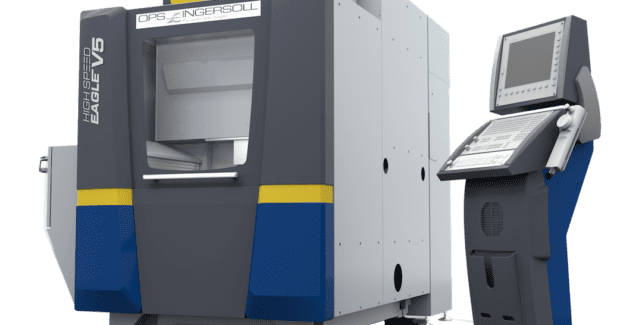

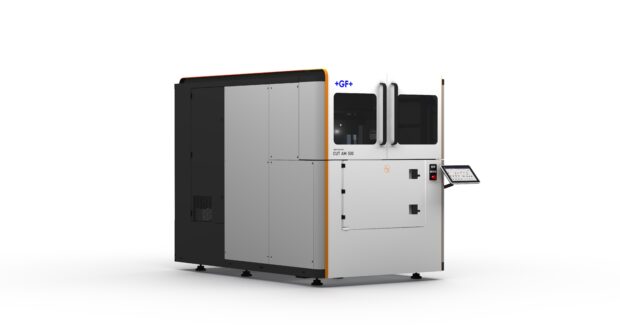

High-Precision, Reliable Parts Processing for Tool Mold and Die Makers

GF Machining Solutions’ MILL P 500 vertical milling machine maintains positioning accuracy over extended machining times. Its Step-Tec spindle reduces secondary manual polishing – and it comes standard.

Manage Abrasives Spend, Improve Productivity with New Weiler Program

With a step-by-step assessment to gather data related to the use of abrasives, the Weiler Consumable Productivity Program weighs costs against output so users understand the best abrasives for their application.

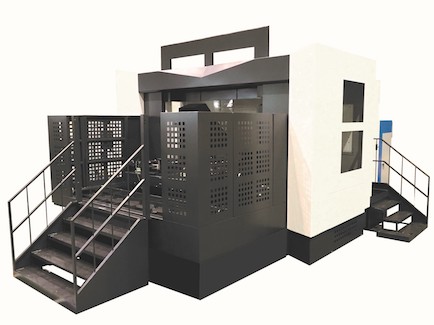

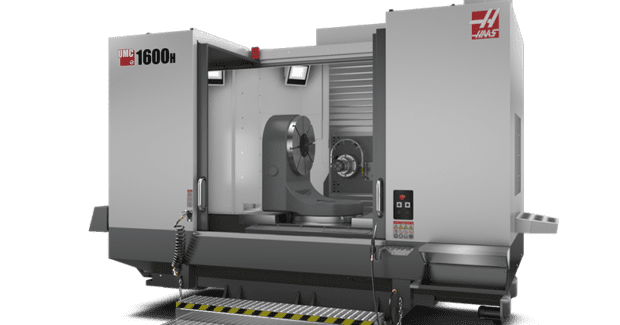

Compact Horizontal Machining Center with New Controls

The crisp new paint scheme on Methods Machine Tools’ KIWA KH-4100kai is just the beginning of design features its predecessor lacked. New componentry inside, including 0i-MF Plus FANUC controls, improve the planning, machining, and chip flow on this four-axis HMC.

New Data Definitions Added to Industry Terminology Standard

Additive manufacturing, robotics, and machine tools are among the updates to MTConnect Institute’s 1.6.0 version released last fall. One unexpected but highly relevant term – humidity – is significant to AM processes and therefore included in the new version.

Goodbye, Farewell, Auf Wiedersehen, Adieu – Siemens CNC Trainer Reflects on 46-Year Career

CNC expert Randy Pearson says memories of the industry’s great people will fill his thoughts while he’s enjoying all his favorite outdoor activities in retirement. He adds a word of exhortation to manufacturing: Don’t stop training the next generation.

Two New PPE Headphone Designs

ISOtunes’ satisfies individual user preferences for hearing protection with its new LINK Bluetooth earmuff headphones and the EXTRA 2.0 earbuds that are water-, dust- and sweat-proof. Affordable and built with long-lasting battery life, both products are OSHA and NIOSH compliant.

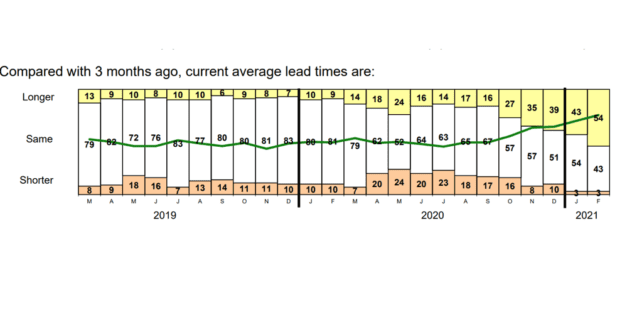

Report: Metalformers’ Concerns Continue Over Lead Times

PMA’s March Business Conditions survey results show 60% of respondents say lead times have increased, up from 54% in February. Even so, half of respondents forecast improved economic activity for next three months.

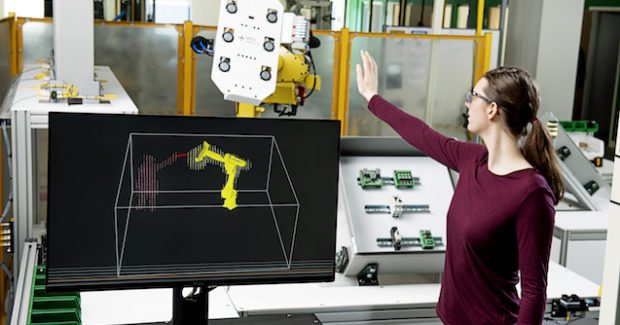

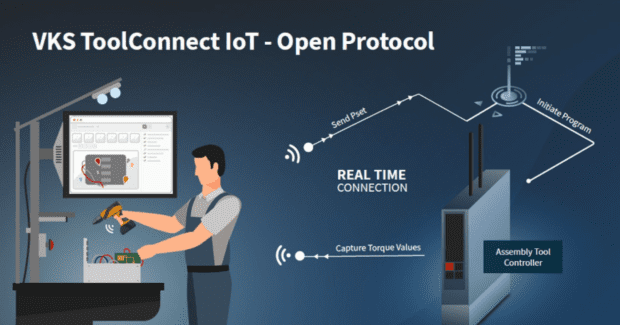

CNC and Robotics Integration Simplifies Operations

The Quick and Simple Startup of Robotization (QSSR) from FANUC America enables FANUC CNCs to directly program robots through the G-code – special operator training in robotic programming language not required.

Award-Winning Safeguarding Solution for Industrial Robots Lowers Collaboration Costs

Veo Robotics’ FreeMove sensors-and-software system uses advanced computer vision and 3D sensing to safely turn a high-speed, heavy-load industrial robot arm into a collaborative robot (cobot) that’s faster – and thus more productive – than traditional cobots.

Cost-Efficient Material Storage and Retrieval Systems

Eurostorage U.S. licensee Athena Manufacturing manufactures customized storage-and-retrieval systems that enable one employee to pull out a heavy drawer of sheet metal and profiles. The elegant and ergonomic designs are low maintenance as well.

High-Speed Cobot Ensures Safety Without Compromising Productivity

Designed to support intermittent interaction between human and industrial robot, ABB Robotics’ 1100 Swifti CRB (for “collaborative robot”) automatically slows, stops, and restarts depending on an employee’s presence in preprogrammed safety zones.

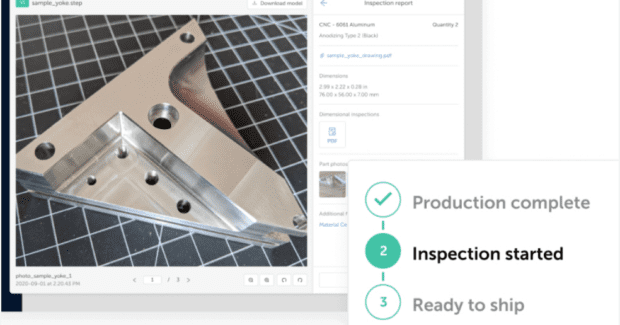

Digital Manufacturing Platform Adds Quality Services

Hardware product teams need not choose between speed and quality because Fictiv delivers both with the integration of new quality services into its digital thread. Customers who depend on precision parts in such industries as robotics, healthcare, aerospace, and automotive have the assurance of consistent manufacturing results at an unprecedented pace.

Scanning Kit for Ultrasound Examinations of Pipe Elbows

When used with any instrument in Zetec’s Topaz family, the ElbowFlex provides high-resolution C-scan images of corrosion and other damage. It saves significant inspection time compared to conventional ultrasonic testing (UT) and grid systems.

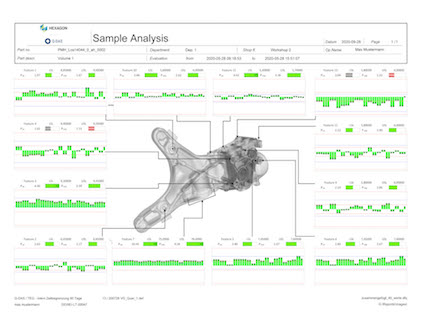

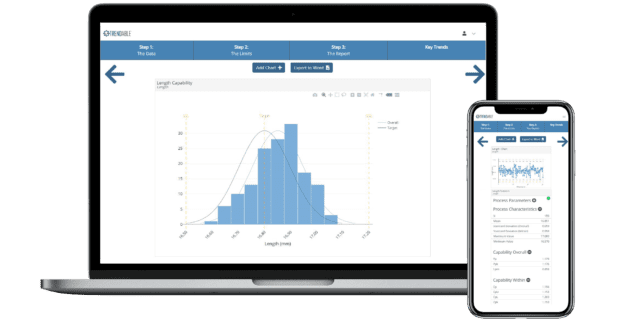

Seamless Workflow from CT Scan to Full Statistical Analysis

Volume Graphics integrates Q-DAS’ qs-STAT statistics software with computed tomography (CT) scan data analysis to provide the basis for a deep assessment and continuous improvement of industrial production processes.

Lab-Quality Elemental Analysis In The Field with a Lightweight Tool

The smallest and lightest handheld XRF analyzer available, Thermo Fisher Scientific’s Niton XL5 Plus enables manufacturing professionals to make informed decisions that impact workplace safety while improving productivity and mitigating user fatigue.

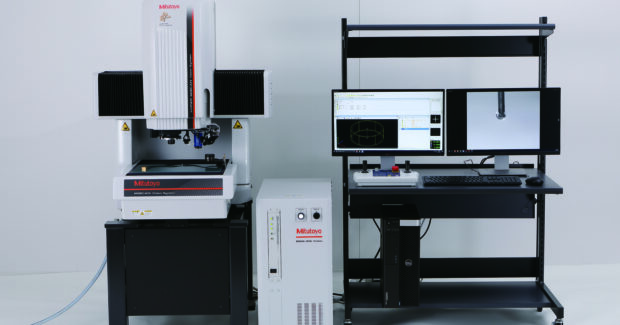

Multisensor Vision System Provides Larger Field of View (FOV)

Starrett’s AVR-FOV 0.14X has a 0.14 magnification lens. When combined with “superimage” technology that stitches images together and a touch probe, operators on the shop floor see more of each part, no matter how complex, they inspect.

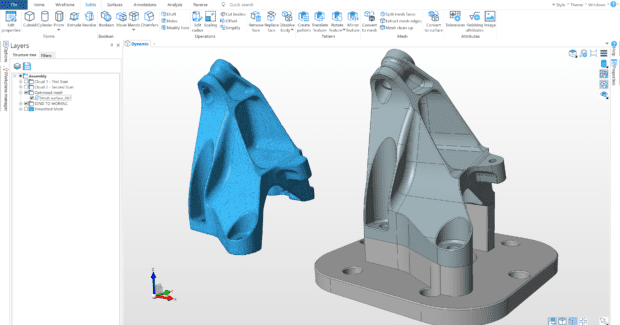

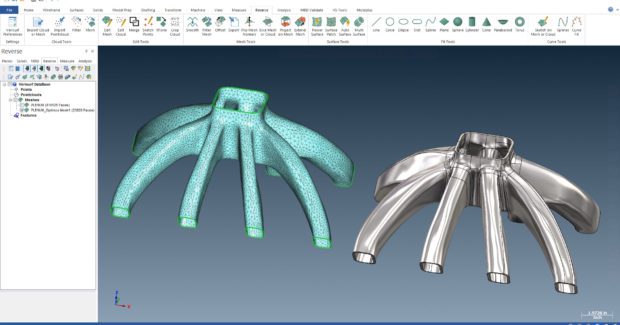

Reverse Engineering Software Provides Digital Twin That’s Ready for Manufacturing

Designed from the ground up from metrology scan to manufacturable model, REcreate software from Hexagon Manufacturing Intelligence aims to uncomplicate the reverse engineering digital workflow by reconciling incompatible data types and technologies.

Gear-Cutting Shop Hops Hurdles With Tool-Holding Investments

A woman-owned Massachusetts company solved its feed and speed struggles with conventional side-lock and collet holders by turning to HAIMER shrink fit products. Short projection length with the Ultra Short Power Shrink creates more rigidity, and the Power Mini helps operators handle hard-to-reach areas.

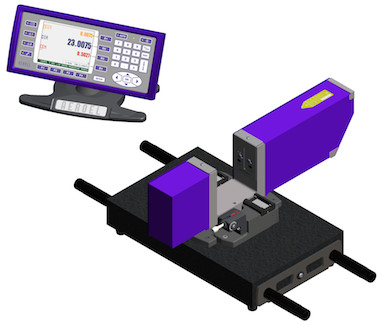

Electronics Evaluation Box for Basic Metrology Applications

Heidenhain’s Gage-Chek 2000 is an embedded plug-and-play system for the company’s encoders that supports measurement of 1D values. Two variants are ideal for positioning tasks on multiple applications.

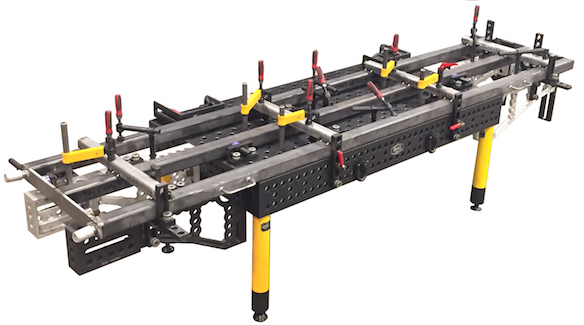

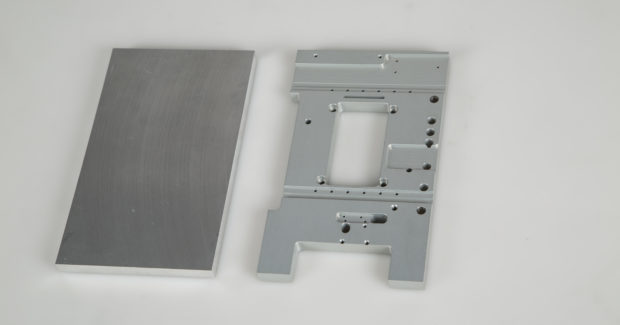

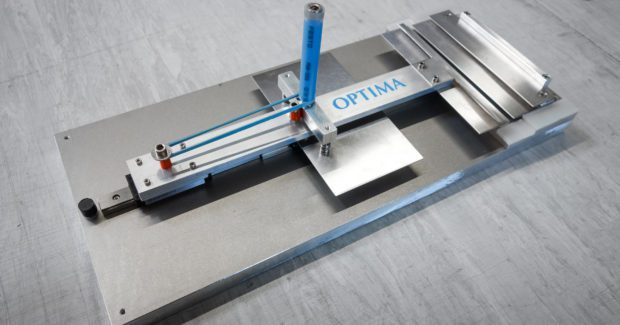

Easy-to-Operate Measuring Tables Virtually Eliminate Variability

Exact Metrology is representing Raytech Measuring Systems, an Iowa designer and manufacturer of shop floor metrology solutions for measuring sheet metal, fabricated and machined parts, and cut-to-length bar stock. SPC software for quality tracking and reporting reduces operator-to-operator variation.

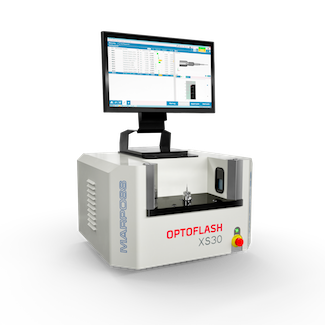

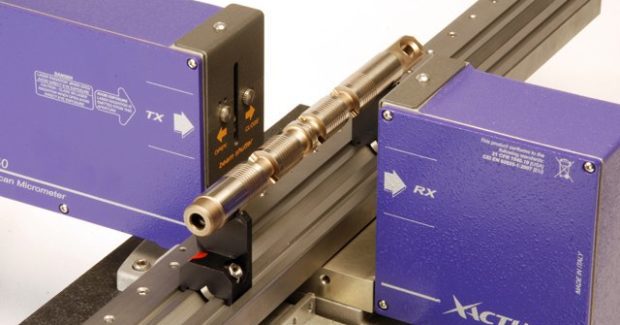

Optical Measuring Systems Anyone Can Configure

Optoquick or Optoflash optical testing systems from Marposs build efficiency into the measuring process and archive all measurements so they’re easily retrievable. Both technologies feature software updates in five and four models, respectively.

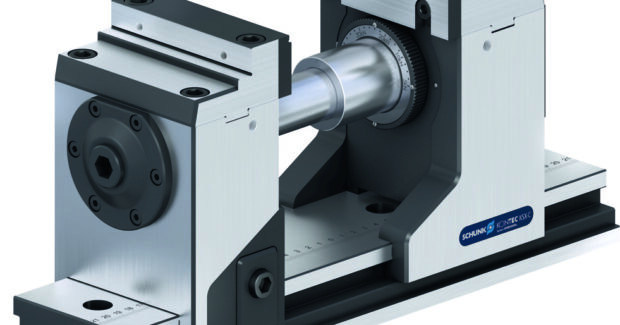

Single-Acting 5-Axis Vise for 6-Sided Machining

An active jaw pull-down function enables Schunk’s Kontec KSX-C2 vise for 5-axis machining centers to securely hold the smallest of parts for machining of a sixth side. Quick-change system enables exchange of a large number of system jaws within seconds without tools.

Excellent-Value Dual-Force Precision Vises

Palmgren’s dual-force precision vises combine quality, high precision and a wide range of clamping capacities at an affordable price. They’re suitable for everything from high-volume production to prototyping.

World’s Most Powerful Vacuum Gripper Cost-Effectively Lifts Heavy Loads

Capable of lifting 44 pounds (20 kg), OnRobot’s electrically powered VGP20 vacuum gripper performs the same heavy-duty tasks as a pneumatic gripper for a fraction of the cost and complexity. Compatible with all major robot brands.

An Electromagnetic Chuck for Virtually Any Application

An increasingly popular alternative to standard mechanical workholders, magnetic chucks lower setup time and provide access to all sides of a workpiece. They’re particularly helpful for holding circular workpieces during hard turning and free state grinding.

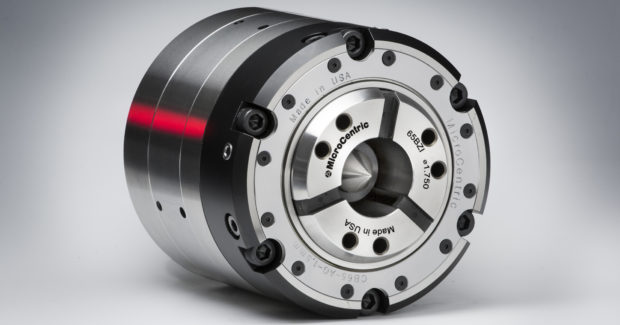

Jaws Firmly Grip but Don’t Damage Fragile Components

Designed for MicroCentric, Northfield, and other precision workholding manufacturers’ air chucks, Dillon Manufacturing’s full-grip pin location jaws hold fragile components securely in place without marring their surface.

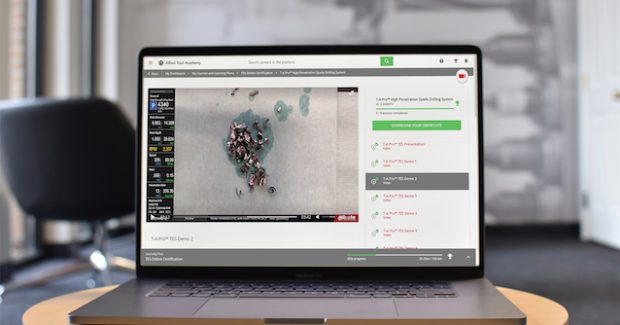

Allied Tool Academy Open for Registration

With modules featuring the same in-depth tooling training as Allied Machine’s three-day, in-person training events, the company’s new online platform enables distributors and product end users to learn on their own schedules. Ten courses are available now, comprising product overviews, demos and short quizzes, with more content to follow.

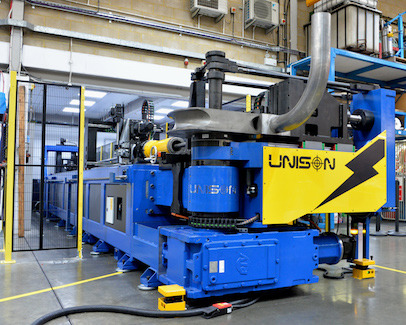

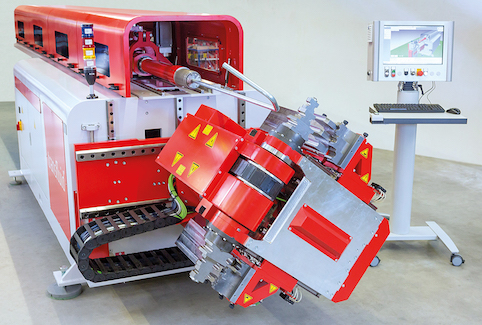

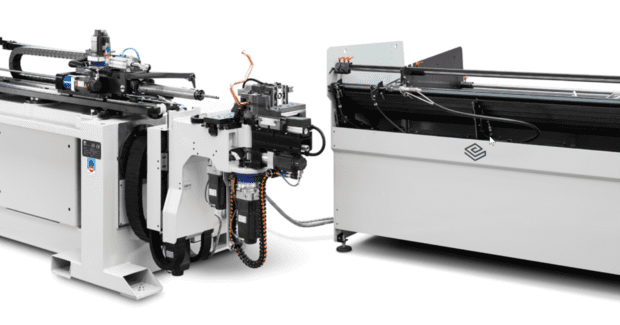

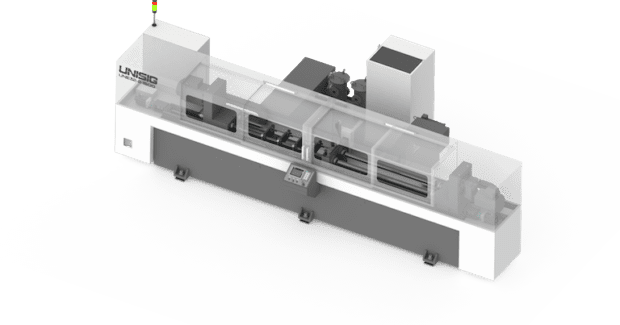

Control System Upgrade Makes Faster Tube Manipulation A ‘Breeze’

Unison’s upgraded Unibend software creates speed improvements, reduced pause time between process movements, and other time-saving features for its Breeze tube bending machines. Customers bending significant quantities of tube – such as those in the automotive sector – stand to benefit the most.

YOY Positive Trend for U.S. Manufacturing Technology Orders

AMT reports over $322.5 million in January 2021 U.S. Manufacturing Technology Orders, a decrease of 29% from December 2020, but a 12% increase over January 2020, and the third straight month of year-over-year gains.

Cleanroom-Ready Gripper for Demanding Applications

OnRobot’s IP67-certified, collaborative 2FG7 parallel gripper is the latest addition to OnRobot’s range of no-fuss, all-electric gripper products. Deployed within minutes, it’s designed to handle demanding payloads, even where space is tight.

Super-Hard Materials for Friction Stir Welding

Department of Defense project will create AI-materials tools to design recipes for a new class of materials tailored to high-temperature applications.

Machine Cuts Through Titanium Like Butter

That’s what General Electric Global Research said about Blue Arc, an EDM-like process it developed to rough aircraft engine components out of huge blocks of difficult-to-cut alloys. Mitsui Seiki has sold the first commercially available CNC machine that incorporates the technology.

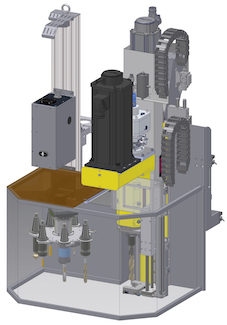

Economical Automation Solution for High-Mix, Medium-Volume Jobs

With the updated JobShop Cell PRO, Methods Machine Tools offers manufacturers a multiaxis simultaneous vertical machining center with multiple end-of-arm and infeed/outfeed options. The efficiency-enhancing cell can be immediately shipped.

5-Axis Machines Cut Diverse and Complex Shapes In One Setup

Automation options for DVF Series simultaneous 5-axis vertical machining centers from Doosan Machine Tools America save time and money by enabling shops to run production parts overnight and quickly switch over to prototype parts.

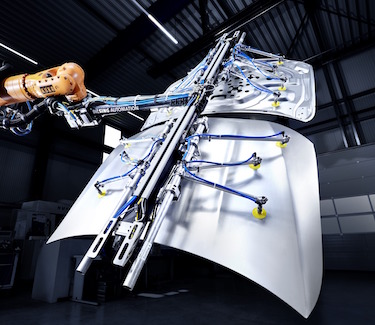

Safely Inspect Small-Diameter Tube and Pipe Welds in Real Time

Suitable for outside diameters of 0.2 to 8 inches (5 to 200 mm) and maximum bead widths of 0.4-inch (10 mm), Xiris Automation’s WI-2200 weld inspection system incorporates a Class 2 laser that won’t injure employees.

PC Software Maximizes Weld Flaw Detector’s Capabilities

Flexible and customizable WeldSight software for Olympus’ OmniScan X3 phased array flaw detector saves time and effort. In addition to advanced screening capabilities, the program enables inspectors to quickly optimize multiple tools for analyzing complex geometries.

Monitor Ensures Oxide-Free Titanium Welds in Automated Applications

Huntingdon Fusion Techniques’ updated PurgEye 500 Desk weld purge monitor is equipped with PurgeNet. The networking device connects to smart accessories including the drive system for automatic welders and orbital welders and a light accessory for visual warning.

Compact Cladding Cell Accommodates Diameters Up To 3.25 Feet

Fronius has taken a simple, compact solution for cladding applications on smaller parts and developed it for larger tasks. The all-in-one cell’s controls support two processes: TIG hot wire and a two-wire SpeedClad Twin process that’s three times faster.

Ultrasonic Spot Welder Provides Consistent High-Quality Results

Attention, electric vehicle component manufacturers! According to Emerson Automation Solutions, the Branson GMX-20 MA’s dual linear bearing design makes the actuator the most rigid and precise actuator in the ultrasonic metal welding market.

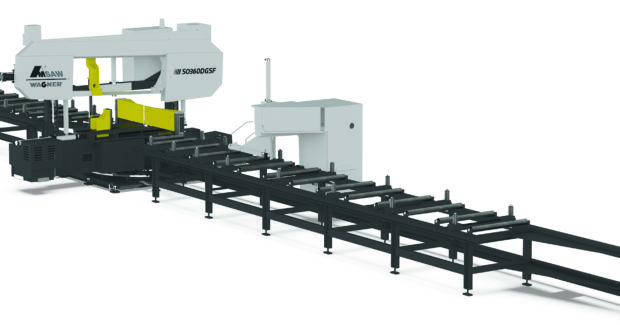

Two Versatile Bandsaws

The EXT at the end of these two Wellsaw model numbers stands for “extra.” The 1316S-EXT swivel-head miter bandsaw provides extra-wide capacity, and the V20F-24 EXT vertical bandsaw provides extra-tall capacity.

48-Inch-Diameter Table Blast System

Although Viking Blast & Wash System is primarily a custom manufacturer, the company gets enough requests for a 48-inch table blaster that the one-wheel machine’s a standard offering. Add a second wheel to completely blast an intricate part or lower cycle time.

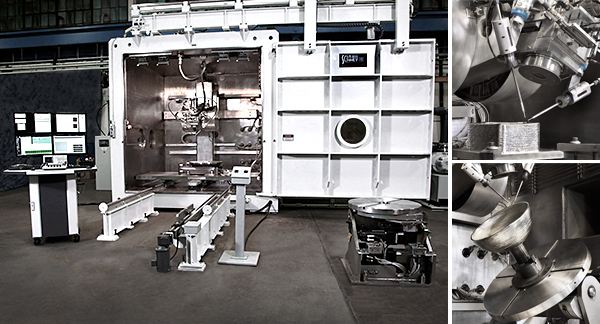

Re-engineered Vacuum Furnace Accommodates Various Sizes, Speeds, and Processes

Featuring intuitive control software with an extensive material database and process simulation, Ipsen’s updated Turbo2Treater supports a wide range of hardening processes. Compact design fits in standard truck or shipping container.

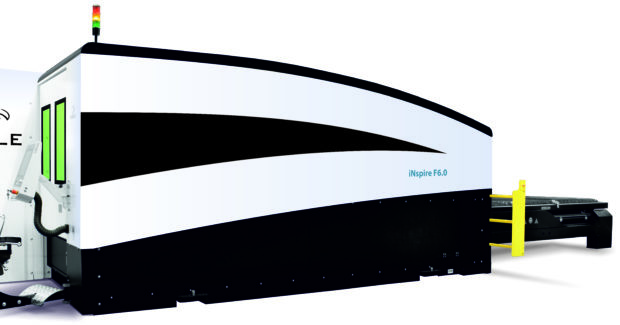

Compact Sheet Metal Fabricating System Safely Handles Wide Variety of Materials

Featuring gull wing doors on the front and back and side sliding windows, the fully enclosed FiberCELL fiber laser cutter from Kern Laser Systems enhances shop floor safety without compromising part loading and unloading. Available in six wattages.

Integrated Controls and Data Management Optimize Powder Coating

Gema’s OptiCenter All-in-One combines electrostatic delivery and powder delivery into a single control unit. MagicControl 4.0 data management system enables complete automation that provides consistent-quality powder coating.

Hamann To Retire From Dynabrade

The maker of portable abrasive power tools for grinding, deburring, filing and sanding bids its president and CEO farewell on March 31.

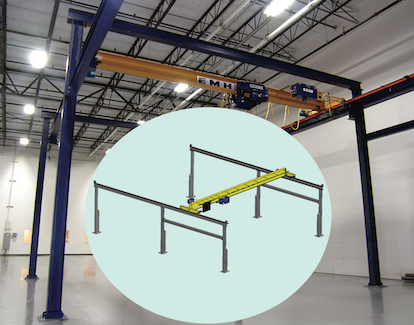

Wider, Taller Crane System Adapts Where It’s Needed

Engineered Material Handling’s NOMAD XW, the latest in its modular, freestanding line of bridge cranes, assembles easily with bolts and most can be installed without footers, thanks to practical design details. Choose from options to suit 1- to 4-cell manufacturing systems, as well as optional travel speeds, and battery or rechargeable radio controller.

Lucifer Builds Custom Dual-Chamber Furnace

A Midwest company has put a new Red Devil unit into service to heat treat steel parts in-house. Cost effective and customized with safety features, the RD8-KHE18 furnace offers space-saving working dimensions of 12 x 14 x 18 inches in both chambers.

MESA Announces Version 7 Release of B2MML-BatchML Specifications

Brought up to date with the ISA-95 standard, Version 7 adds important new elements to B2MML including spatial locations, material and other resource testing information, standardized error message handling, and work calendars.

Fast, Powerful 5-Axis VMC Simplifies Program Simulations

The VARIAXIS i-800 NEO from Mazak features optional proprietary technology that optimizes processing and facilitates more accurate configuration of machine programs. Easy automation helps less experienced operators quickly build confidence to run complex parts.

Next Gen Horizontal Machining Center Expands Range of Applications

Mazak’s HCN-6800 NEO comes with upgraded standard features and numerous options, too. Its cycle times are faster, its footprint is smaller, and its range of part and tool capacities are wider.

Smart Visual Inspection Technology Meets Metrology Products

A new Mitutoyo-Kitov agreement will lead to the integration of Kitov technologies in Mituoyo’s metrology solutions. Look for future development of more solutions to come from the new partners as they combine Mitutoyo’s measurement technologies with Kitov’s planning and inspection technologies.

Unison Ups Product Support Scope, Accessibility with ‘UltimateCare’

The rebranded service program facilitates selection of the right maintenance solutions, and also offers additional services such as CAD modeling, component prototyping and process optimization. Customers can choose services ala-carte or in tailored, bundled agreements.

Paperless Parts Launches Search Function to Expedite Quoting

Paperless Search, a digital search tool enhancing the quoting platform from Paperless Parts, provides easy access to all formats of historical data, and it’s available now to Paperless Parts customers.

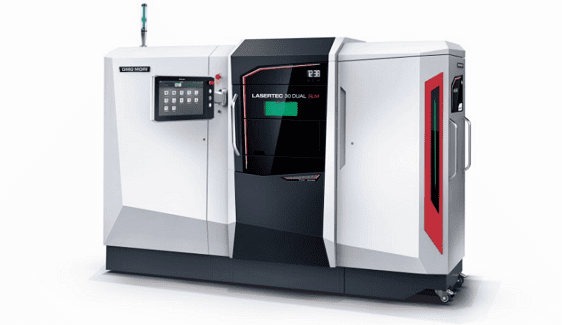

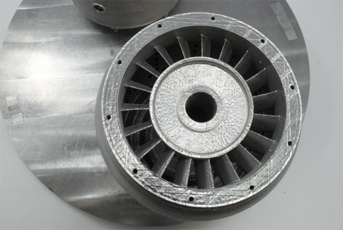

New AM Alloy Swings Open 3D Options for Turbines and More

EOS NickelAlloy IN939 from German 3D metals printer company, EOS, combines high-temperature strength – at over 1500 degrees F – with crack and corrosion resistance. Its potential ranges from industrial gas turbine and microturbine parts to turbochargers, power industry parts and other extreme-conditions applications.

Specialty Purging Prevents Oxidation in CMV Steel Welds

Available in many pipe sizes, HotPurge from Huntingdon Fusion Techniques HFT is an inflatable, specialty system designed to address the inherent challenges of keeping mechanical properties intact. Through continuous purging, it can maintain oxygen levels below 100 ppm.

Bending Under Pressure – To Process Enormous Tubes

Schwarze-Robitec’s CNC 60 DB Twin booster bending machine steps up to the uncompromising specifications of a major Russian boiler manufacturer. Boilers need maximum surface area to ensure highest heat transfer – the machine handles the required narrow bending and tight tolerances.

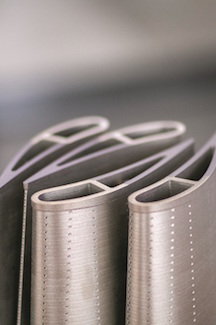

The Ultimate CNC Tube Bending for Subcontractors

Unison’s 130-mm diameter tube bender is a robust, multiradius and multistack machine with the benefit of additional component length to give buyers an edge in the subcontractor marketplace. Users are able to achieve right-first-time manufacturing for repeat subcontract work.

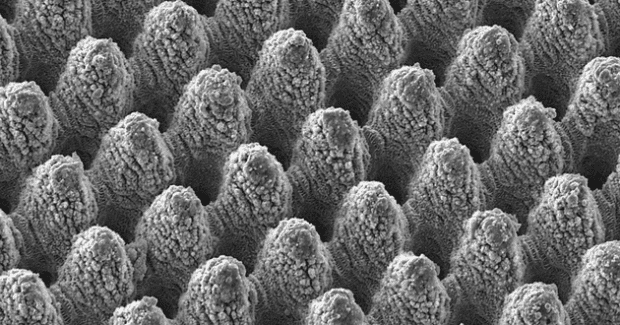

In Development: New Laser System Creates Grease-Repellent Metal Surfaces

Funded by an EU grant, a European consortium is treating metal with high-power lasers that texture the surface with microscopic spikes that prevent grease and bacteria from sticking. Rough micro-topography acts like a bed of nails to stop dirt or liquid from attaching.

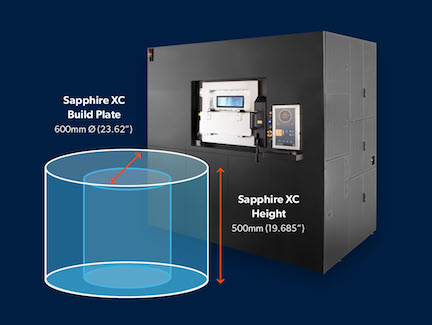

Change 3D Metal Printer’s Deposition Head While Printing, Coating

Chiron Group’s flexible additive manufacturing machine – the Chiron AM Cube – is designed with laser metal deposition technology to work efficiently in the mechanical engineering, tool manufacturing, energy production, and aerospace sectors. Its three deposition heads can perform different functions on a single workpiece.

Nitrogen Generation, Gas Mixing Products Reduce Costs and Floor Space

Bystronic Inc. and MSS Nitrogen Inc. partner to sell Bystronic’s Nitrocube nitrogen generation and NitrO2 gas mixing products, powered by MSS, in the North America market. Nitrocube’s nitrogen purity is 99.999%, while NitrO2 mixing can triple laser cutting speeds.

Report: Lead Times A Growing Concern, Metalformers Say

While a majority of manufacturers predict no change in economic activity in the coming three months, according to PMA’s February report, a shortage of metal supply is alarming, according to association’s president. Lead times for steel have more than tripled in five months.

Acquisition Expands AIMS Metrology’s Service Footprint

Now under AIMS ownership, Measurement Specialties Inc. has supported CMM brands including Sheffield – as retrofitting and upgrading business has increased over the last year, AIMS is now poised to broaden its customer service offerings.

Industrial Magnetics Inc. Acquires Walker Magnetics

The acquisition marks expansion of Industrial Magnetics’ permanent, electromagnetic and electro-permanent magnetic technology and systems for industrial applications, the company says. Walker’s 125-year legacy carries considerable strength in the workholding segment.

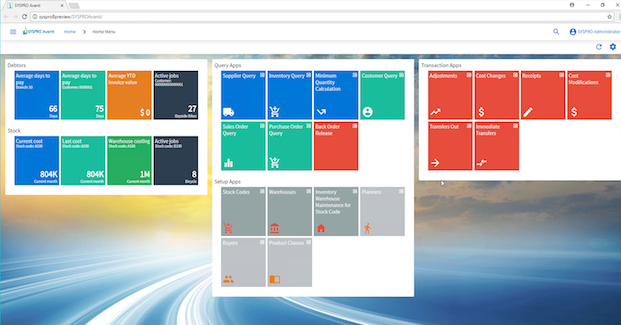

OPC Connectivity Solution Collects, Distributes Factory-Wide Data

GF Machining Solutions has launched Version 1.0 of the Open Platform Communications (OPC) Unified Architecture (UA) interface as a single connectivity solution for North American manufacturers. It will help reduce machine downtime, monitor performance across entire facilities, automate operations, and ensure manufacturing process compliance.

Cart-Based Material-Handling System Maximizes Storage Space

Signode’s StorFast is an automated storage and retrieval (ASRS) system that provides high-density, lights-out, 24/7-access to products and materials. Unlike cranes, the cart-based system allows for unlimited configurations.

Tower System Provides Lights-Out CNC Machine Tending

Designed to automatically feed CNC machines, Kasto’s Unitower CNC is a smart material-handling system controlled by software that monitors production to optimize order handling and ensure necessary NC programs and tools are available.

Handheld Analyzer For Metal Alloy Analysis

Smaller and lighter than other laser-induced breakdown spectroscopy (LIBS) analyzers, Rigaku Analytical Devices’ KT-100S identifies difficult materials including low-alloy steels, stainless steels, high-temperature alloys and lithium.

Ultrasonic Thickness Gage with Temperature Compensation

The 38DL Plus with 38-Link wireless adaptor for connecting to the Olympus Scientific Cloud (OSC) saves time and money by minimizing human error and optimizing data management.

Handheld Sensor Reliably Measures Countersinks on Various Surfaces

LMI Corp.’s LaserGage HS742 3D sensor is a 3D laser profiler and that uses blue-laser technology and application-specific algorithms to overcome the challenge of measuring countersinks on solid, translucent, shiny, and opaque surfaces with repeatable results.

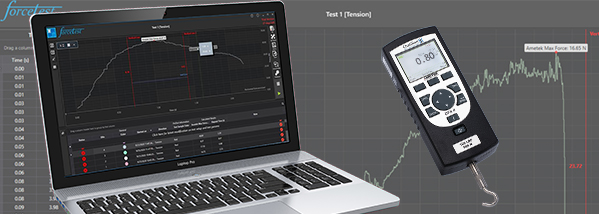

Updated Software Expands Force Gage Versatility

Ametek’s Chatillon DFS II Series digital force gage with ForceTest 2.0 software gives the operator a highly flexible testing system while additional functionality. The operator also benefits from live test graphs and data analysis.

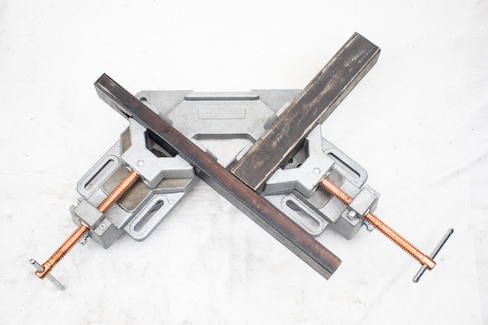

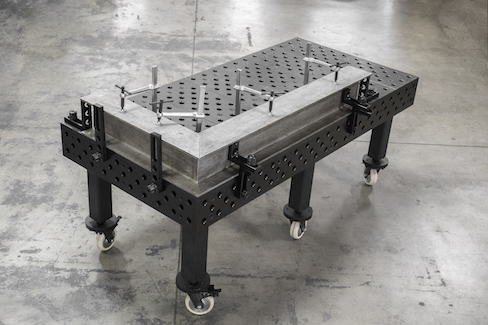

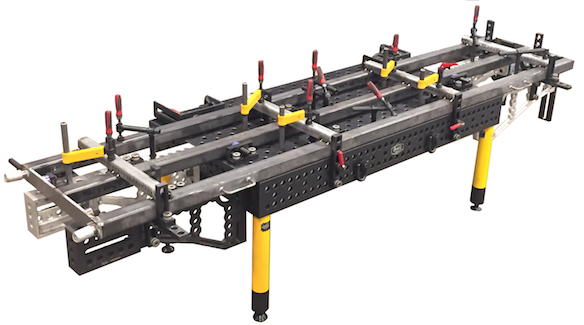

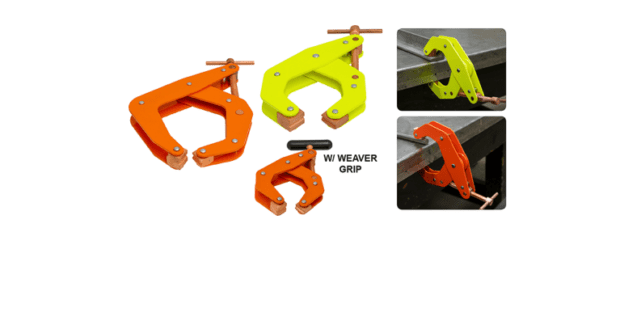

Multiconfiguration Welding Workholder

Strong Hand Tools’ universal vises quickly and securely clamp stock of different thicknesses at multiple angles into place. They can be removed from the base and used separately.

Vise Kit Makes Automating Much Easier

Schunk’s Tandem PGS3-LH 100 clamping force block for basic aluminum and plastics machining has an integrated flange and comes with a console plate for easy mounting to machining tables, dividing heads, and clamping stations.

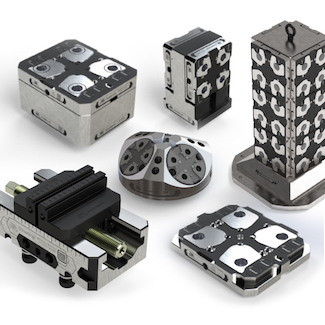

Workholders Enhance Productivity for More Than CNC Machining

Comprising self-centering vises, quick-change bases and mounting accessories, Mate Precision Technologies’ 52/96 zero-point product line can be used for inspection, CMM, cleaning, washing, assembly, and additive manufacturing as well as on 3-, 4- and 5-axis machining centers.

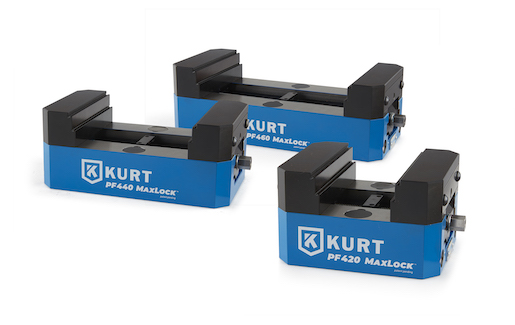

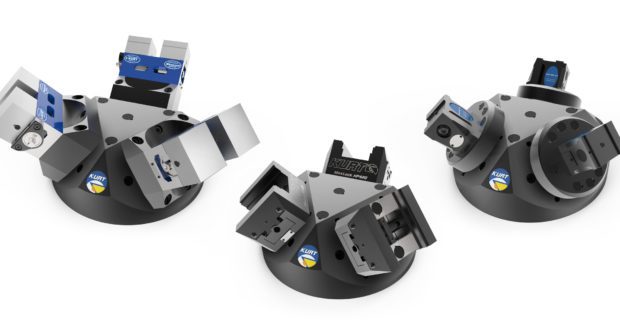

Three Robot-Ready 5-Axis Vises

Kurt Workholding replaces HP-model vises with Precision Force (PF) MaxLock vises featuring a patented locking mechanism that holds parts securely, keeps them square with excellent repeatability, and are affordable.

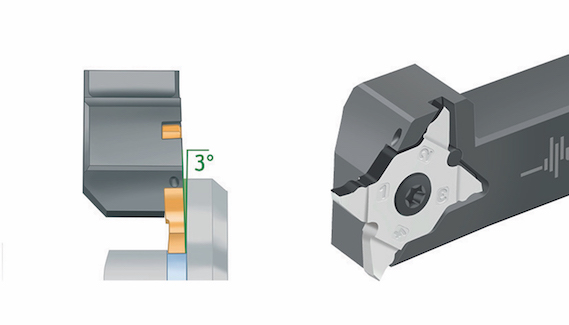

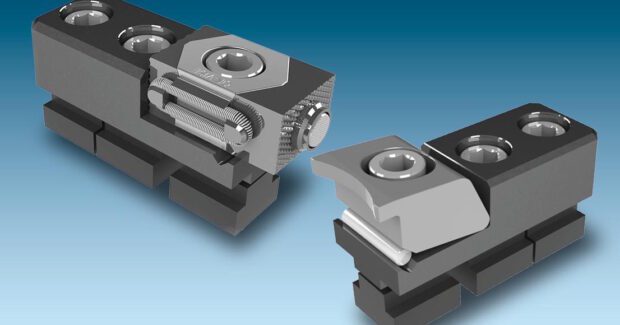

Redesigned Insert Clamp Improves Rigidity

The toolholder for Horn USA’s Supermini grooving and boring tools applies a tensioning wedge to the insert’s face rather than circumference, increasing rigidity and repeatability.

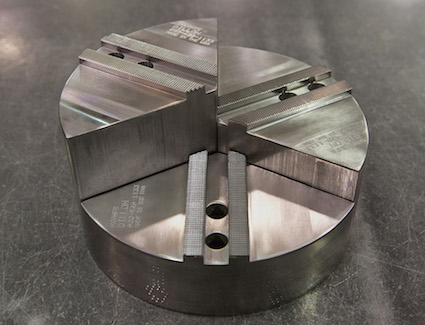

Choose the Material that Will Provide the Strongest Grip for Your Workpiece

Dillon Manufacturing can manufacture soft or hard and full-grip special top jaws in a wide range of materials and configurations to ensure chucks provide maximum grip for an application.

Manual Swing Clamps Provide the Best of Both Worlds

Destaco combined the best features of pneumatic swing clamps and straight line action clamps to create a low-cost workholding option for fixture builders. The manually actuated swing clamps eliminate the need for air.

Small-Footprint Vertical Machining Centers (VMCs) for Small Part Production

An economical option for small shops that need a second machine or additional spindle, all three models of Palmgren’s vertical machining centers (VMCs) have a 10-tool magazine with automatic changer and user-friendly portable handwheel.

VERY Heavy-Duty Horizontal Machining Center (HMC)

Ideal for the demanding aircraft, automobile, power generator, mold-and-die, and semiconductor industries, Niigata’s 5-axis HN80E-5X horizontal machining center (HMC) produces 1.65-ton parts almost 50 inches in diameter and 40 inches high.

5-Axis Vertical Machining Center (VMC) Provides Large Work Envelope Relative to Footprint

Engineered for tight-tolerance work for the mold and die, aerospace, and energy industries, Mitsui Seiki’s compact Vertex 100 provides a large workpiece capacity so operators can process a wider range of parts.

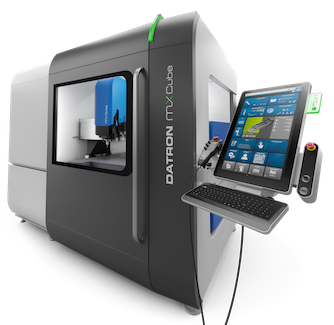

Smaller-Footprint, Easier-to-Use Vertical Machining Center (VMC)

Mazak’s VC-Ez 20 is the first of three vertical machining centers (VMCs) that offer much the same functionality and performance as previous models, but in a more compact and more affordable package.

High-Speed, Large-Capacity 5-Axis Vertical Machining Center (VMC)

Thanks to a 75% increase in work envelope and high traverse rates, Matsuura USA’s MAM72-52V processes larger-diameter and heavier workpieces than its predecessor. Integrated tower pallet enables lights-out production.

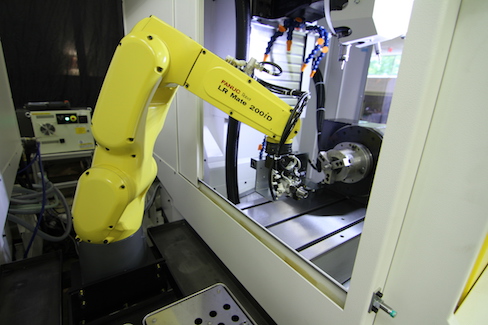

How to Easily Automate Vertical Machining Center (VMC) Tending

With Quick and Simple Startup of Robotization (QSSR), Fanuc simplifies the process of connecting and programming a Fanuc robot or cobot. The all-in-one package enables operators to program the robot using the machine’s CNC.

Machine and Turn 2-Ton Workpieces in A Single Setup

Doosan’s DHF 8000ST is a single-table version of the company’s DHF 8000 5-axis horizontal machining center (HMC) that incorporates a turning function so manufacturers can save time by moving from roughing to finishing with one setup.

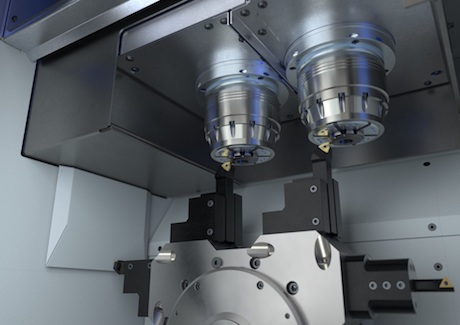

Twin Spindles Machine Large Components With Great Precision

Available in 4- and 5-axis versions, Chiron’s dual-spindle DZ 22 has a fast spindle for machining aluminum and aluminum alloy workpieces and a strong spindle for machining hard materials and large tools.

CAMBRIO Appoints New Vice President

Nick Spurrett joins the senior leadership team as vice president of GibbsCAM. He’s a sales veteran with 25 years of manufacturing software and CAD/CAM experience.

Updated Software Simulates and Automatically Corrects Bending Sequence

Available in two versions with varying levels of functionality, transfluid’s Windows-based t project software links geometry and material data to achieve precise bending results.

End Formers for Aerospace, Tank, and HVAC Components

Two models – the 2.5 and 4.0 – from Kaast Machine Tools ensure consistently accurate strength-promoting beads in materials up to 0.15-inch (4mm) thick. Available with mechanically (ZSM) or hydraulically (ZSH) driven upper rolls.

Track and Control Stamping Operations in Real Time From Wherever You Are

IRMCO Advanced Metalforming Lubricant Technologies’ iNSIGHT enables metal stampers to track the rate of chemical consumption by part and process and compare the data to tool life to pinpoint the actual cost per part for each process in a facility.

Two Electric Upcut Tube Saws

Two standard models – the eRB80 TS and eRB150 TS – electric upcut tube saws from Innovative Engineered Solutions (iES) cut diameters up to 3.5 inches (90mm) and 5.9 inches (150mm), respectively.

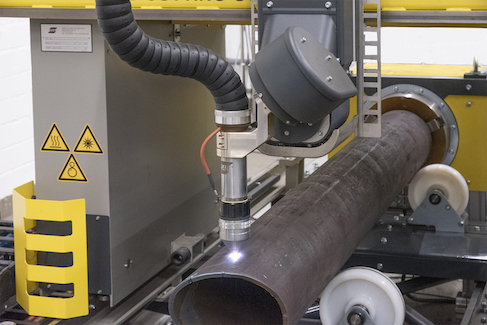

Fully Integrated System Automates Pipe Cutting From Start to Finish

HGG Profiling Equipment’s ProCutter900 RB increases throughput by continuously feeding, cutting and profiling, and moving pipe out. The small-footprint machine’s accuracy dramatically reduces post-cutting grinding, fitting and welding time.

Automated Centerless Tube Grinder

An automated version of Glebar’s TF-9BHD infeed/thrufeed centerless grinder, the TF-9D features the widest work wheel on the market. Customizable interface designed for automation and 8-5/8-inch-wide work wheel combine to increase throughput.

Autonomous Tube/Wire Bender Enables Lights-Out Production

Featuring a compact layout, integrated loading/unloading capability, and easy-to-use programming software, BLM Group’s Smart Bender enables an operator to go from design to part in one click and walk away.

Xometry Launches ‘Xometry Pay’

The new invoicing platform enables manufacturers to provide payment terms to customers, accept credit cards, and receive job advances.

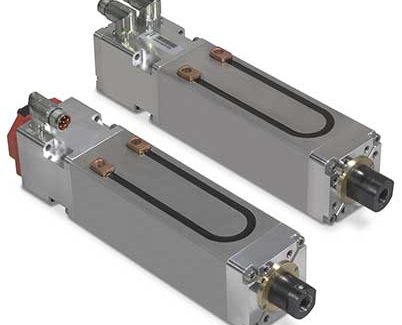

High-Force Actuators Support Robotic Sheet-Metal Welding

Tolomatic’s CSW and CSWX Compact ServoWeld welding gun actuators for robotic spot welding integrate a 3,507-lbf and 4,047-lbf, respectively, actuator into a hollow-core servo motor for faster resistant spot-weld cycles.

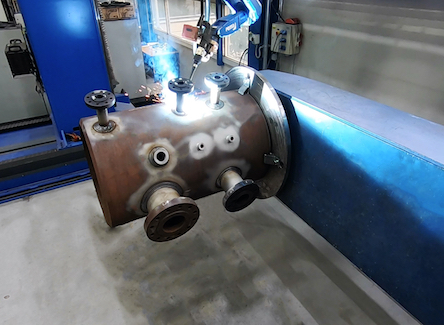

Cobot Simplifies and Improves Large-Pipe Welding

Requiring just 4 square feet of shop floor space, Novarc Technologies’ spool welding robot (SWR) enables inexperienced welders working on pipe spools up to 30 feet long to monitor and adjust parameters to pipe variations in real time.

Portable and Easily Adaptable Welding-Automation Solution

Lincoln Electric’s Fab-Pak Cobot Cart enables small- and medium-sized fabricators to justify investing in automation by providing a mobile, easy-to-program, and safe robotic welding solution.

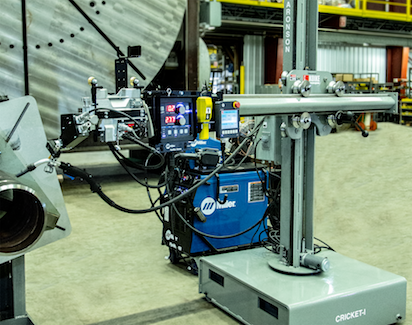

Space-Saving Automated Welding Package for Pipe Fabricators

Koike Aronson Ransome’s pipe-welding package incorporates the Cricket-I manipulator. Providing 20-IPM lift speed and 150-pound load capacity, the manipulator ensures productivity increases without sacrificing floor space.

6-Axis Welding Cobots Provide Maximum Flexibility

Fanuc adds 15- and 33-pound-payload welding cobots to the ARC Mate product line. The arc welding cobots’ easy-to-program interface supports both simple and complex applications using advanced features.

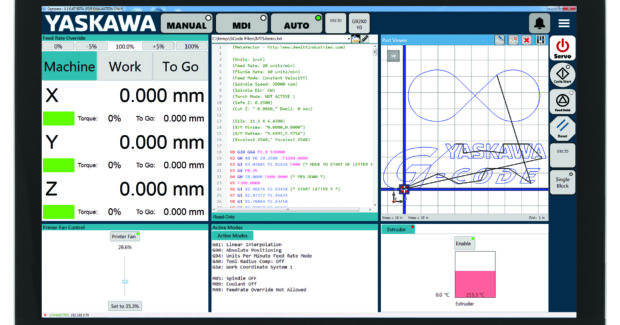

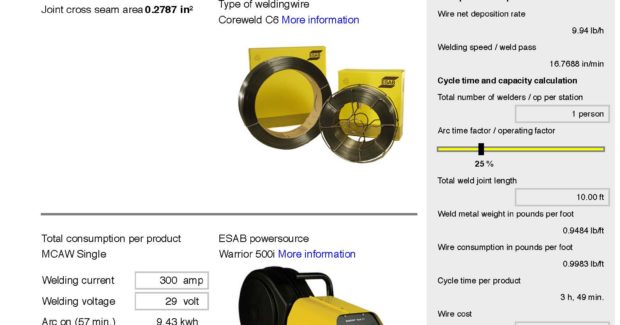

Pre-Engineered Cell Eases Transition to Automated Welding

ESAB and Yaskawa have partnered to offer small-to-medium-sized manufacturers and fabricators a pre-engineered welding cell that’s easy to set up and operate: the XCellerator.

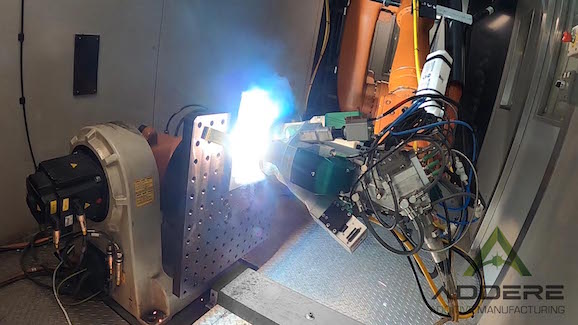

Bystronic Enters Automated Welding Market

Bystronic is selling three robotic welding options – Micro Cell, Compact Cell and Compact System – in the U.S. They’re configured by the German manufacturer Cloos Robotic Welding, which handles installation, training, and service.

Three Cobots with Built-In Vision Systems

Delivering payloads ranging from 9 to 31 pounds and reach up to 4.25 feet, the TM5, TM12, and TM14 cobots from Techman Robot can “see” and automatically reposition objects using a smart user interface.

All-in-One Kits for Quality Assurance Using Universal Robots’ UR3e Cobot

Designed for Universal Robots’ UR3e cobot arm, the Q-Span Workstation from New Scale Robotics comes with everything necessary to automate small-part measurement inspection. You can improve gage R&R and boost capacity without adding headcount.

Two-Arm Cobot Doubles Efficiency Without Sacrificing Safety

Even though they have two arms, Kawasaki Robotics’ duAro cobots fit into a single-person space while providing enough room for an employee to safely work alongside. Two models provide 8.8- and 13-pound payloads.

Three Updated Cobot Models Offer Greater Connectivity

The “A” in Hanwha’s HCR-3A, HCR-5A, and HCR-12A stands for “advanced.” Three cobot models improve on their predecessors by offering customizable solution packages that incorporate artificial intelligence and mobility technologies.

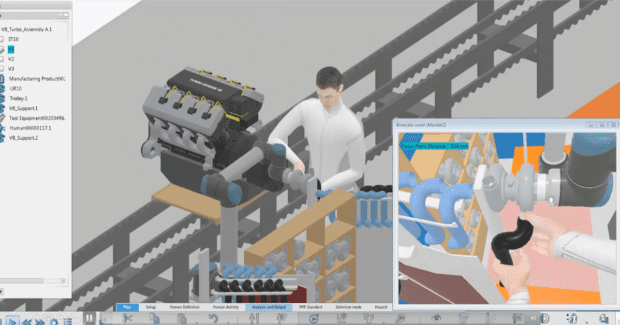

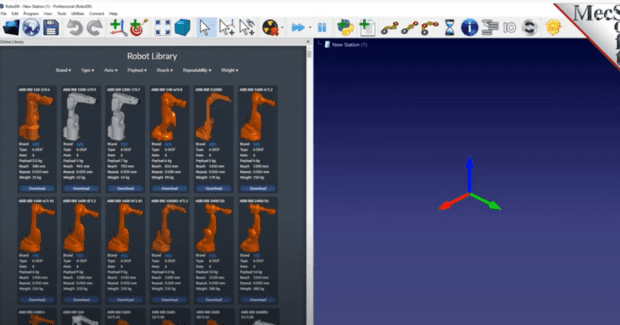

Design the Ideal Floor Layout for Cobotic Production and/or Assembly

Delmia Robotics’ software from Dassault Systemes maximizes automation initiatives by enabling manufacturers to design and virtually test a drilling-and-riveting, arc welding, spot welding, and/or material handling line before rolling it out.

End-Effector Kits Increase Cobot Flexibility

Do you own a Fanuc CRX cobot? Thinking of buying one? ATI Industrial Automation’s end-effector kits make the most of your investment by enabling applications including deburring, orbital sanding, tool changing, and force/torque sensing.

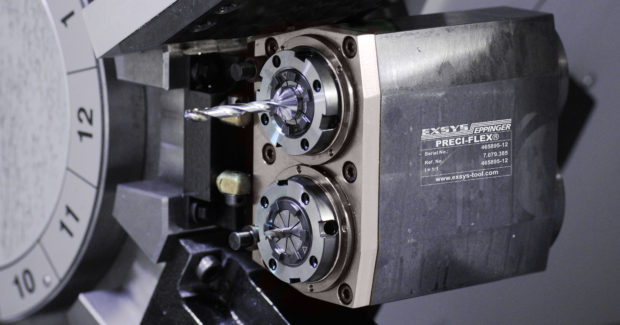

EXSYS Tool Becomes ‘EXSYS Automation’

The company is moving to a wider focus on automation, as demonstrated by the introduction of Eppinger robotics, rotary tables and more. While continuing to offer the high-precision Eppinger tool holders and services it’s known for, EXSYS Automation says it will also roll out new Eppinger offerings designed to “revolutionize chip making.”

2020 Ends with Large Leap in U.S. Manufacturing Technology Orders

According to the latest monthly report from AMT – The Association For Manufacturing Technology, December orders increased nearly 40% over those in November. Pent up demand, depleted inventories, continued reshoring, several COVID vaccines, and a lot of cash on the sidelines are creating an environment for a good start to ’21.

Match Spindle Performance to Specific Machining Need

Suitable for high-volume large, heavy part operations, Mazak’s HCN-5000 is a horizontal machining center that offers users the option of high-speed or high-torque integral motor spindle, so they can align proper speed and power for the job at hand.

Lincoln Expands Warranty

Lincoln Electric now offers a standard 5-year factory limited warranty for Advanced Welding Equipment. Covering Power Wave Advanced Process Welders, PIPEFAB Welding Systems, AutoDrive Robotic Wire Feeders and more, it’s the most extensive warranty in the industry, the company says.

Stationary Workholding Promotion In Progress

SMW Autoblok’s is reducing the price on numerous premium clamping products. They’re all Proofline sealed to protect against corrosion.

Expedited Order Picking with Easy On-Off Access

Combilift’s Aisle Master Order Picker – the AME-OP – has all the functionality of the conventional model, but it’s designed with a low, single-step floor on both sides of the truck. Made for navigating narrow aisles, it’s available in weights from 3300 to 6000 lbs. and can reach as high as 39 feet.

Wayland Additive Awarded ISO 9001 Certification

The maker of NeuBeam says the certification objectively affirms the quality of their innovation in metal AM for production applications, as well as the company’s commitment to customer satisfaction.

Videos Explain Welding Careers, In Digestible Segments

American Welding Society has introduced “AWS ARCademy,” a series designed to ‘make a positive impact on up-and-coming welders’ without overwhelming viewers with too much, too soon. New additions will continue to be added, giving students and other welding-wannabe’s a ‘crash course’ in welding basics.

Manufacturing Software is ‘Single Source of Truth’ For Product, Process, Quality

Siemens extends Xcelerator portfolio with enterprise-wide quality management system. Teamcenter Quality provides an all-geographies collaboration platform that also enables engineers to establish their own parameters for excellence.

Free Multimedia Kits Support Workforce Development

NIMS is partnering with e-learning platform developer Edge Factor to release ‘Experience’ toolkits to inspire students and equip those who influence them with videos and guide materials. In 2021, three themes will be released at no cost: “Women in Skilled Trades” (March through April), “Rock MFG DAY” (September through October) and “Apprenticeships” (November through December).

Dapra CEO Retiring March 1

Linda Pilvelis has served at Dapra Corp. for over 45 years, the last 17 as its CEO. Shawn Lawlor from Bartell Machinery Systems has been appointed as her successor.

FANUC America Launches Cobot E-Learning Website

The site gives manufacturer employees a clear overview on setting up and programming a CRX collaborative robot. The online tutorials, as well as product and partner deep-dives, are available for free.

Lucifer Furnaces Completes Delivery to U.S. Air Force

The company has announced 18 models have been delivered to bases around the country over the last year.

NIMS Appoints Four New Members to Board of Directors

Annika Langéen, Allen Reid, Paul Myles, and Sara Lozano were installed during the last board meeting of 2020.

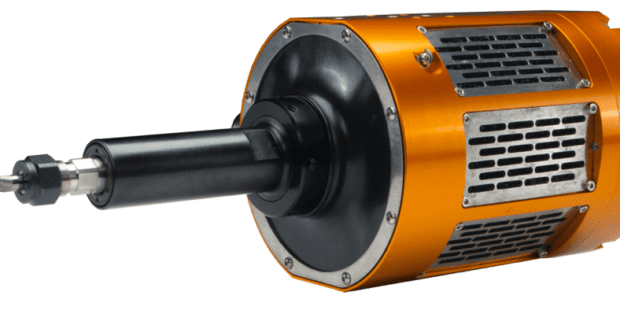

Suhner Opens Tool Repair Center

The new North American service center has larger capacity, new equipment, better organization and more staff. It’s key focus is the repair of spindles, multiple spindle heads, slides and live tooling.

100% Inspection on the Manufacturing Line

Streamlining quality inspections just got easier with Olympus’ Vanta iX in-line XRF analyzer that automates material analysis and alloy ID. Metal fabricators get real-time process monitoring in their 24/7 operations.

Survey: 39% of Metalformers Express Economic Optimism

And according to January’s PMA report comprising input from of 120 metalforming companies, more than half anticipate no change over the next three months.

ABB Launches Preventive Maintenance Service for Robots

For fleets or individual units, ABB’s condition-based service monitors functions like duty, speed, acceleration, and gearbox wear. Real-time data is used to predict potential failure, thereby reducing unplanned downtime.

Compact Turning Center with Y-axis

Doosan Machine Tools’ Lynx 2600SY offers job shops a versatile solution for handling a wide range of projects. Its control is equipped with the Doosan EZ guide conversational programming feature but still retains the traditional G-code programming language.

Vacuum Cup for High Speed Applications

Bilsing Automation’s PFG Series cups are suited for holding steel, aluminum or plastic parts. Their one-part body design parlay into less damage to metal sheets.

On-Demand Learning Center for CNC Programmers

ESPRIT debuts an online, self-paced, learn-anywhere series of e-courses that guide users through numerous machine models and part models to introduce users to different machining processes in ESPRIT.

James Kim Named CEO of Doosan Machine Tools America

With 18 years of director and vice president roles invested in the U.S. operations, Kim has served at Dooson for a total of 37 years. He’s known for establishing trust and building authentic relationships.

First Voice Assistant for Manufacturing Is Here

Athena, launched by iTSpeeX, LLC, interacts with machine tool operators and responds to over 500 human commands to help make them more independent and productive. A driving purpose behind building the technology: To help solve the skilled labor problem.

Two Optical Cutting-Tool Inspection Systems

Omega Tool Measuring Machines adds the Vue with 145x magnification and Vue Lite with 95x magnification to its portfolio of cutting-tool presetting and inspection systems.

Triple-Duty Monitoring System

Nordmann provides systems for tool monitoring and process control for all types of metal cutting operations. The SEM-Modul-e can be used to monitor tools, processes and machines.

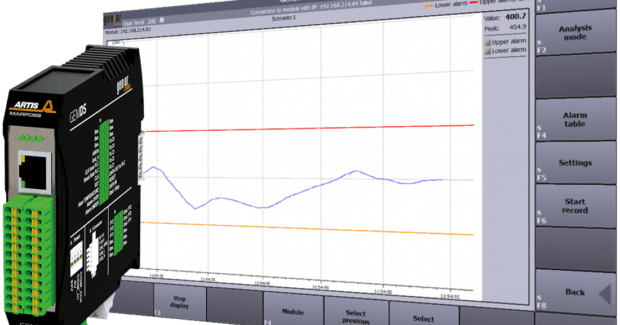

Split-Second Response Enables Predictive Maintenance

The Artis GEMVM from Marposs is a stand-alone spindle-monitoring module that aids in predictive maintenance. Runs on Windows machine control panels or Siemens Linux systems and integrates with Marposs’ Genior Modular monitoring system.

Easy-to-Use Tool Presetter With Large Measurement Range

Capable of measuring 400 millimeters of travel on both axes, Hoffmann Group’s Garant VG Basic features an intuitive program that makes the cutting-tool presetter easy to set up and operate. Use it at the machine or a production island.

Compact Inverters Optimize Machining Performance

In addition to a wider screen that allows for a split view, Gen 3 drives for Heidenhain’s TNC 640 control system allow for jig grinding and trochoidal milling capabilities on smaller machine tools.

Remote Tool-Monitoring System Provides Real-Time Machine Control

Caron Engineering’s browser-based TMAC 3.0 enables real-time monitoring and system control from any network-connected device for any machine tool brand. It’s ideal for unattended CNC machining because no operator intervention is required.

Broken-Tool Monitor Doesn’t React to Nuisance Faults

Allora International’s PCS-100 sensor kicks in only when a drill, tap, reamer, or end mill breaks, not when chips are accumulating; and ignores common tool-to-tool diameter differences. Speeds exceed 80 cycles/minute to keep up with the fastest machines.

Manufacturing Industry Invited to Take Reshoring Survey

AMT and the Reshoring Initiative will use the survey results to identify which processes, products and components face the most pressure from imports and which offer the biggest opportunities to reshore. Part of AMT’s “Rebuilding the Supply Chain” initiative, the survey is open to OEMs, job shops, technology suppliers and distributors through the end of February.

Shop Chair Eliminates Five Common Pain Points

The seat, backrest, and arms of the American-made Vyper Chair are adjustable. Additional features such as a footrest increase welder and fabricator comfort and productivity by correcting posture and reducing back strain.

Protect Workers When They Can’t Socially Distance

Zoneworks EZ Employee Separation Barriers from Rite-Hite protect employees who can’t work more than 6 feet apart. Lightweight panels made of clear PVC are easily wiped down to further mitigate exposure to airborne viruses.

Dual-Purpose Device for Monitoring Skin Temperature

Palmer Wahl’s portable HSB50 Heat Spy can be used to verify the reading of hand-held infrared thermometers and thermal cameras and/or provide greater-accuracy measurements for thermal imaging temperature scanning systems.

Metal-Safe Sanitizer Aids Fight Against COVID-19

MicroCare’s Stereze products are formulated using a high-purity alcohol-based solution which is focused on high-performance cleaning. They’re safe to use on metal tools and machinery and stand up to rigorous scrubbing on rough surfaces.

Lighweight Exosuit Minimizes Risk of Back Injury

According to the U.S. Centers for Disease Control and Prevention, back pain is the top work-related health problem. The Apex from HeroWear minimizes the potential for injury by making loads 50 pounds lighter when an employee lifts and bends.

Cheaters Make Deciphering Text Easier and Safer

ANSI- and CSA-rated for high impact, Pyramex Safety’s Carhartt Braswell Readers are available in three magnification levels. Hard-wearing frame and lens are made from virtually shatter-resistant polycarbonate.

Gloves Protect Without Slowing Metalworkers Down

The lightweight SmartCut BKCR2403 glove from Brass Knuckle Safety Products provides abrasion- and cut-resistance protection for employees performing metal assembly, fabrication, and manufacturing work requiring fine motor dexterity and tactile sensitivity.

Year-Over-Year November U.S. Manufacturing Technology Orders Up 1.4%

While November’s $330.3 million represent a decrease of 13.3% from October, AMT’s president says it’s clear ‘the sector did not fare as poorly as originally predicted.’

Marposs Introduces Remote Video Conference Testing and Acceptance Service

Tests are livestreamed through Zoom, and customers can provide immediate feedback – then their requested alterations are made in real-time.

Quick-Change Robotic Arm Gripper

The RV36 Gripper from Kurt Workholding saves space and money while improving efficiency with quick-change, customizable jaws and custom accessories. Its double-acting piston allows for maximum clamping and un-clamping force.

ESPRIT CAM and Alma CAM Create Robot Additive DED Programming

The partnership has resulted in a validated workflow that provides end users with dedicated additive toolpath planning and programming, as well as robot programming, simulation, verification, collision detection, and code generation. Engineers can also use the technology to achieve the above functions for subtractive finishing.

Heavy-duty Helmet Shields Against Welding Fumes, Particulates

ESAB’s Savage A40 PAPR has a two-stage replaceable filtration cartridge that meets NIOSH certification and removes 99.9 percent of airborne particles. Providing comfort, performance and value, this helmet will be available at the end of January 2021.

Cool Factor Outside, High-Tech Welding Helmet Inside

Miller Electric’s Metal Matrix and Gear Box helmets have the graphical identity that resonate with welders while giving them the protection they need. The Digital Elite and Classic Series helmets have built-in technology that automatically activates for optimal optical safety.

Protect Welders’ Eyes with True-Color, Auto-Darkening Filters

Weldcote introduces high-definition technology for passive-style welding helmets designed to reduce eye fatigue. Offering a view area of 5.15 square inches, the filters come in four choices of shade.

Bernard and Tregaskiss Launch Joint Website

The companies invite the industry to visit tregakiss.com to find helpful customer service, technical support and welding distributors for personal assistance, along with answers to frequently asked questions about product manuals, replacement parts and product maintenance.

Enhance Cut Quality by Matching Beam Shape to Part

Mazak Optonics’ Optiplex Nexus 3015 Fiber S7 is a 7kW 2D flying optics fiber laser-cutting system with beam-shaping capability that enables operators to select beam size and shape according to material thickness.

IT Problem-Solver Achieves 15-Year Milestone at Global Shop Solutions

Director of Cloud & Technology George Thuo is best known for finding a way to solve customer challenges. He’s a team leader who oversees all things cloud, including uptime, security, software updates and more.

New COO at Kitagawa Northtech

Shawn Luschei will be responsible for daily operations at the North American headquarters near Chicago. He’s been a sales professional with the company for many years and has deep workholding and tooling product experience.

LVD Announces New Trade Name in North America

LVD North America is the new moniker for the company’s sales & service division for this region of the world, replacing the LVD Strippit brand.

Manufacturing Process Enhances Cutting Wheel Durability

Weldcote’s A-Prime Plus line of cutting wheels lasts longer because they’re manufactured via a multistep granulation process that evenly distributes each individually coated aluminum oxide grain.

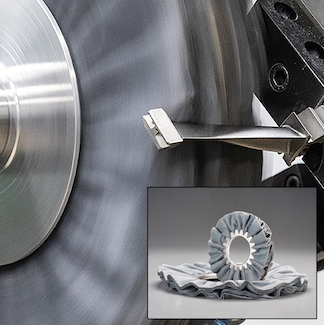

Seamless Finishing Wheels for Fine-Tolerance Work

Shur-Brite finishing wheels from Superior Abrasives produce a satin finish without the visible transition lines often caused by traditional flap brushes. Their seamless design ensures conformability by providing superior cushioning at low speeds.

Burnishing Tools for Virtually Any Production Need