Welding

Filter by Process Zone:

How to Improve Jobsite Productivity and Safety

Easy to setup, the heavy duty 4-Pack Rack from Lincoln Electric reduces jobsite cable clutter by accommodating up to four Flextec 350X welders.

The Critical Role of Next Generation Welding Helmets

More comfort. Improved safety. Higher productivity. Better weld quality. Reduced costs. Increased bottom line. This is only the beginning of the reasons why metal fabricators should stay updated on new helmet technologies. There’s more.

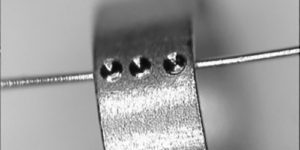

Nd:YAG or Fiber Laser Micro Welding?

There are a number of choices for laser for micro welding. Here are the factors to consider why and when one laser might be chosen over another, and how to select the best option for your specific application.

Advances in Welding

Here are some innovations that can help you increase productivity, improve quality and reduce costs in your welding operations.

Choosing the Right Drive Roll is Key for Smooth Wire Feeding

Is your wire welding operation being challenged by poor feedability, birdnesting, burnback, or clogging of the gun liner? If so, you may be using the wrong type or size of drive rolls for the job, or using improper drive roll tension. Here are some tips to help you prevent downtime and its associated costs due to poor wire feeding.

Understanding Stainless Steel Filler Metals

The properties of stainless steel offer corrosion resistance, toughness and strength, a good appearance and longer useful life. But there are some challenges when welding stainless steel. Consider these tips and best practices, including proper filler metal selection, to get the most from stainless steel welding applications.

Coldwater Machine Named Level 1 FANUC Integrator

This status opens up new automation opportunities for them in appliance, automotive, and aerospace applications.

New Sales and Marketing Hires at Abicor Binzel

Jens Schleicher is now their global managing director of sales and marketing and Jason Jamiel is an automotive key accounts manager in North America.

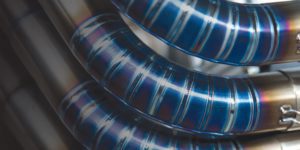

Let It Flow: Tube & Pipe Welding

As business picks up for tube and pipe fabricators, they must reduce their setup times and become more versatile in the flow of work they are able to handle, all while increasing their productivity to remain competitive. Here is some of the latest tube and pipe fabrication and welding equipment that can help these shops smooth out jobs so that their work goes with the flow.

New NextGen Chair at IWDC

Rodney Huber has been appointed to the leadership role of the Next Generation Group.

Plug and Block Pipe of All Shapes and Sizes

Pipestoppers pipe plugs and stoppers from Huntingdon Fusion Techniques HFT are used for leak testing, weld purging, debris stopping and pipe freezing for repair or maintenance work in large oil and gas plants and refineries.