Welding

Filter by Process Zone:

Fume Extraction Gun for Large Weldments, Confined Spaces

The 300 amp Clean Air Fume Extraction MIG gun from Bernard reduces smoke at the source with a small vacuum chamber that provides good joint access and visibility, along with a 360 deg vacuum hose swivel on the rear of the handle for improved flexibility that reduces operator wrist fatigue.

Toyota-Mazda Announce Alabama Factory

Their new $1.6 billion joint venture in Huntsville will eventually produce 300,000 vehicles a year and employ 4,000 people.

Dengensha America Adds New Sales Engineers

They add Doug Becker as a senior sales engineer and Jim Pfeil as a sales engineer.

Welding Equipment for Pipe and Tube Fabrication on the Jobsite

The Dynasty 280 DX with CV from Miller Electric includes Auto-Line technology and can TIG weld 0.012 in to 3/8 in aluminum and 0.004 in to 3/8 in steel with superior arc performance. It can TIG weld with AC waveforms, including advanced squarewave, soft squarewave, sine wave and triangular wave.

How to Reduce Eye Strain by Optimizing Contrast and Clarity in Welding and Light States

To achieve the perfect weld, operators must be able to clearly see their work. This new lens technology from Miller Electric optimizes contrast and clarity in both welding and light states so that operators see natural color tones and get a crisp, high-definition view of the workpiece.

Welding Equipment for Shop and Field Work in Offshore Yards

The Renegade ET 300iP inverter for DC TIG, pulsed TIG and Stick welding from ESAB weighs 37 lb, produces a top output of 300 amps at 40 percent duty cycle and offers primary power flexibility. They also offer the Rebel EMP 285ic multiprocess welder for MIG, Flux-Cored, DC Stick and TIG welding.

How a Welding System Conversion Increased Production at Exterran by 30 Percent

Take a closer look at how a welding process conversion and equipment standardization in their Brittmoore pipe shop in Houston helped to significantly increase productivity and improve on already-high weld passage rates in only a few months.

The New Generation of Resistance Welding: Not Your Father’s Process

Resistance welding is a sub-specialty in the world of metal joining that was often ignored and taken for granted in the past, but not anymore: so many exciting new process technology developments are now taking place in this field that shops are trying to keep up so they can capitalize on the new business opportunities being created.

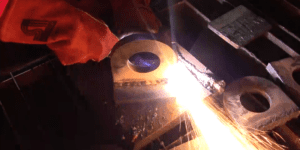

Plasma Cutting Consumables Significantly Reduce Grinding Time

FlushCut consumables from Hypertherm use an angled nozzle bore to deliver the plasma arc at a 45 deg angle nearly parallel to the workpiece for closer cuts that dramatically reduce the amount of material left behind and significantly reduce grinding time.

IWDC Adds Regional Sales Manager

Barry Mitchell has joined this cooperative of independent welding distributors that represent over $2.2 billion in sales across North America.