Welding

Filter by Process Zone:

Rugged Cobot Offers 20-Kilogram Payload for a Wide Variety of Tasks

The industry’s first IP67-rated collaborative robot, Yaskawa Motoman’s HC20XP is particularly well-suited for use in damp and splash-prone environments such as food processing. Two speeds optimize cycle time based on risk assessment and process requirements.

Flexible High-Volume, High-Performance Welding Capability

Yaskawa America’s ArcWorld 6000 pre-engineered workcells featuring Motoman AR-series arc welding robots come with virtually everything you need to get up and running quickly and safely. Available in one-, two-, or three-robot configurations.

Big Leap for Fiber Laser Welding

The HighLight FL4000CSM-ARM fiber laser from Coherent achieves advanced, more stable welding results with high thermal conductivity metals. Its dual beam output creates high laser intensity, so material doesn’t heat up.

Reduce Piercing Time Up To 40% on Thick Steel

Thermal Dynamics Automation’s new QuickPierce function speeds the piercing time on 400-amp cutting systems. Their cost calculator demonstrates long-range savings you can realize, thanks to improvements that extend the life of 400-amp consumables.

Save Time, Reduce Human Error with Document Management Software

ESAB’s Weldcloud Notes for generating and managing PQR, WPS and WPQ helps QC personnel and welding engineers monitor the many facets of the welding project – including compliance. It’s also an efficient online tool to track individual welder performance.

Flange Fitting Welding Station Can Remove Need for Crane

Pemamek’s PEMA FF station safely handles bulky tower sections and, depending on part size, you might not need a crane – and its skilled operator – for these challenging applications. It’s also equipped to accommodate diverse flange designs.

Low Cost Monitor for Welding Titanium and Stainless Steel

Huntingdon Fusion Techniques HFT developed PurgEye Nano as an entry level, plug-and-play monitor for oxygen level requirements as low as 10ppm. It gives the welders exact oxygen readings inside the pipe so they know when to begin.

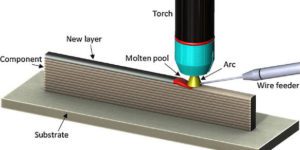

More Manufacturers Take a Closer Look at Wire Arc Additive Manufacturing (WAAM)

Unlike powder-based additive manufacturing, this second method of additive manufacturing uses a standard high-deposition process and readily available materials. Wire arc additive manufacturing (WAAM) is particularly cost-effective for prototypes and small-batch production runs.

Automated Nozzle Makes Light Work of Thick-Wall Welding

Pemamek’s PEMA nozzle welding solution eliminates heavy welding’s drudgery and inaccuracy. Built-in lasers scan the geometry of each layer, which the robot’s control software uses to automatically generate the ideal path for the next pass.

Don’t Risk Weld Failure by Using the Wrong Dam Material

Unlike water-based materials that leak or slip from position, HFT’s weld purge film doesn’t contain water but is water-soluble. After being used to produce quality welds on tubes and pipes, the film dissolves and washes away.

Helmet Protects Welder’s Eyes Before the Arc’s First Flash

Intelligent occupational safety: That’s what Fronius offers in the Vizor Connect. Communicating with the power source via wireless Bluetooth communications technology, the helmet’s visor darkens as soon as the welder turns on the torch.