Welding

Filter by Process Zone:

Precision Hole Technology™ for Plasma Cutting Machines

This system, which is available on ESAB cutting machines and retrofits on many existing ESAB machines in the field, uses the best hole cutting techniques in Columbus.NET programming software to take advantage of the advanced gas control capabilities in m3 Plasma™ systems. The technology also utilizes a unique encoder-based height control and the VISION 5x series of CNCs.

ESAB Opens New Manufacturing Facility

To support steady growth in the North American market, this new plant is responsible for the production of high-performance MIG and submerged arc welding wires, along with premium brand AristoRod and copper-coated wires.

Second Time Around is a Charm

Brooklyn Iron Works had tried MIG consumables from Bernard years before and didn’t think they were the right fit for their application. But, after keeping an open mind and agreeing to a second trial, their reduced downtime and costs eventually led the structural fabricator to convert all of their MIG guns and consumables over to Bernard.

Complementary Cutting: Evaluating Automated Plasma & Oxy-Fuel Processes

Each process has clear-cut advantages, but John Henderson and Dirk Ott of Victor Technologies explore where the real difference lies: in the major cost influences of equipment, consumables, cutting speed, installation, maintenance and cut quality.

What Is Commercial Grade Dedication and When is it Required for Nuclear Grade Welding Consumables?

Regis Geisler of Lincoln Electric explains how a supplier of nuclear-grade welding consumables can know whether or not they are in compliance with Title 10 and the requirements of the Nuclear Regulatory Commission.

ESAB Upgrades Website

The site now includes an Energy Savings Calculator that compares the savings of using various products and Weld Metal Cost Calculator that realizes savings by varying the metal and process.

Lincoln Electric Acquires Wayne Trail Technologies

The welding OEM strategically strengthens its welding automation position in North America by adding this Ohio-based manufacturer of flexible, automated systems that are used in a variety of metal forming, fabricating and joining industries.

No Turning Back: Pipe Welding System Kicks It Up a Notch

Using the PipeworxTM Welding System from Miller Electric, Shinn Mechanical has increased its pipe fabrication quality and productivity with flatter bead profiles, good sidewall tie-in for 30 percent less grinding, and superior weld puddle control – with no wire rejects in over a year.

Thermadyne Changes Name to Victor Technologies

Innovation to Shape the World: In a strategy to reposition itself in the marketplace, the corporate name change leverages the company’s strongest and most established brand.

Resistance Spot Welding of Aluminum Moves to Production Line

Georg Fischer Automotive uses an innovative resistance spot-welding process from Fronius to join die-cast aluminium parts in the vehicle door-frame on the Porsche Panamera.

Job Shop Gets a Square Deal with Metal-Cored Wire

Rick Conrad of Hobart Brothers explains how full-service job shop Square Deal Machining has, by converting to metal-cored wire as part of its continuous improvement process, improved its productivity by 30 percent to 40 percent as a result of having faster, cleaner welds.

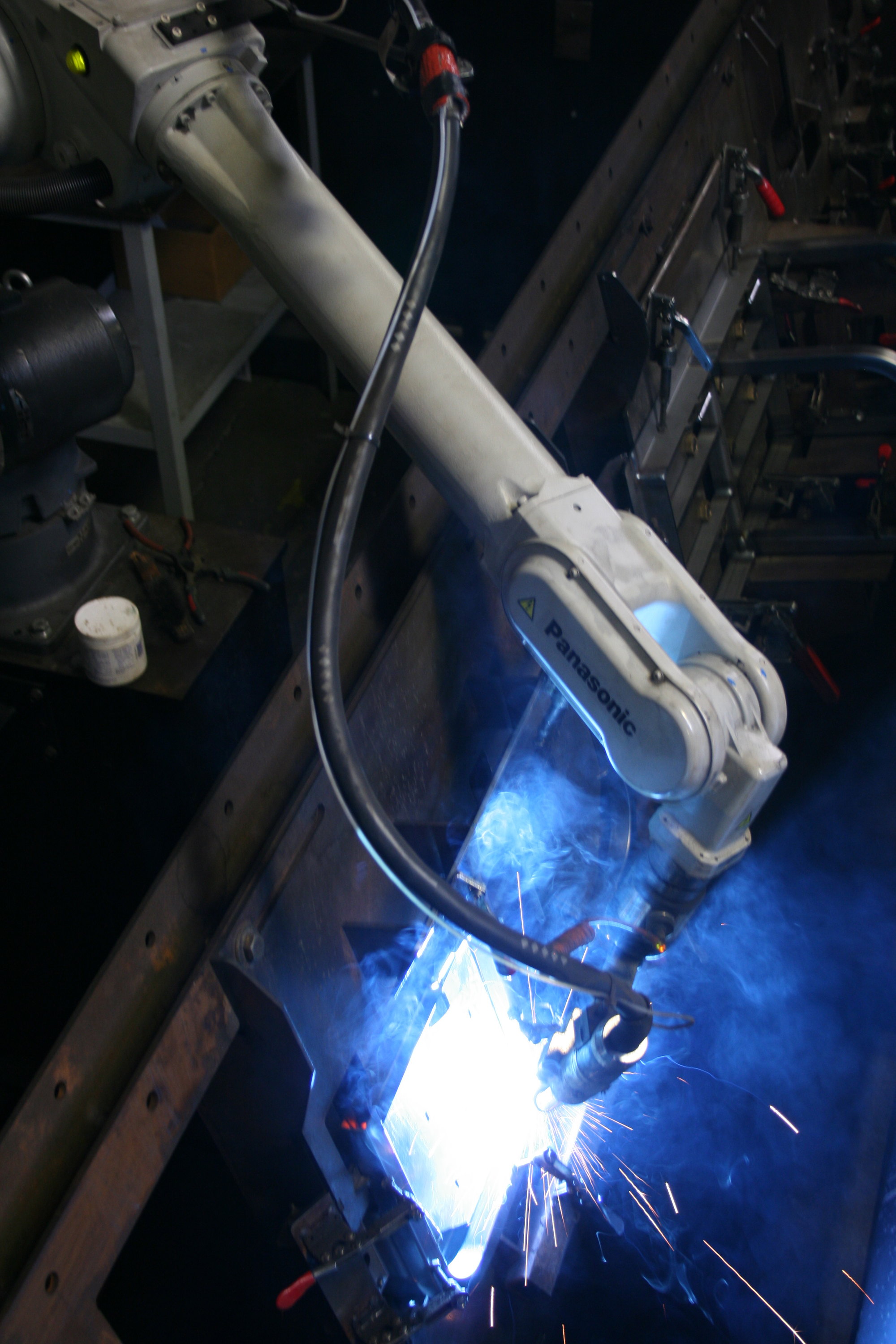

Robotic Work Cells Help Diversify Business

Take a look at how contract manufacturer K-zell Metals can diversify and compete against global competition by bidding and planning fabrication work more aggressively with its increased capabilities and automation flexibility.