Welding

Filter by Process Zone:

Automation for the Small Job Shop: Competitive Advantage

In part two of this three-part series, we walk through the mechanics of process control on the floor, the flexibility and lean manufacturing capabilities of automated welding, and how robots handle all sorts, sizes, shapes of parts – ideal solutions for the competitive job shop.

Percentage of Argon in Mixed Shielding Gas Does Matter

Using a higher percentage of argon can increase the weld metal’s tensile strength, but it provides no additional value and may increase the chances of weld cracking. Here’s why.

Lincoln Electric Receives Boy Scouts of America North Star Award

Youth organization honors Lincoln Electric for active involvement in new Welding Merit Badge program

ESAB Is Proud Sponsor of Operation Fearless

ESAB is proud to help sponsor Operation Fearless, the 1991 Ford Bronco build project underway at the RK Motors Performance Center to honor fallen Navy SEAL hero Adam Brown.

Evana Automation Supplies Custom Screw Driving System to Prominent Products Manufacturer

Evana’s automated solution will reduce manual labor and increase quality assurance for aluminum fencing assembly process.

First SVIA PickVision Machine Tending System Installed in the US

ABB Robotics system at Atlas Copco to tend three Okuma lathes that manufacture parts used in mining applications.

ESAB Sponsors University of Toronto Baja Team in SAE Design Competition

ESAB will support the University of Toronto Baja Team with the donation of welding equipment, consumables and personal protection accessories as they compete to design and build a rugged off-road vehicle.

Simplified Multiprocess Welding Capabilities for On-Site Pipe Welding Applications

This welding system from Miller Electric brings proven PipeWorx pipe welding processes to portable field applications in the refinery, petrochemical, power generation and HVAC industries to improve productivity, uptime and quality.

Engine-Drive Welder Ideal Fit for Pickup Trucks

The quiet, compact Vantage® 300 from Lincoln Electric provides an EPA Tier 4-compliant, multi-process, industrial, diesel-engine-drive welding solution for construction teams, pipe-rig owners and rental-fleet managers.

FILL THE GAP: ROBOTS FOCUS ON QUALITY

Though many might argue that the progression of robotic welding technology has always focused on profit, Heath Suraba of Lincoln Electric explains why you must have quality before you can realize profit.

Low-Alloy Ccellulosic Electrode for Pipe Welding

Pipeliner Arc 80, a low-alloy stick electrode from Lincoln Electric, is designed for root pass welding up to X80-grade pipe, fill and cap pass welding for X70-grade pipe.

MOTOMAN INTERFACE FOR LINCOLN ELECTRIC POWER WAVE POWER SOURCES

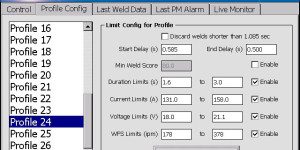

Users can now program weld parameters as work point/trim or amps/volts, along with up to four “Wave Controls” with allowable limits displayed from the process library in the Lincoln power source. Users can also program Lincoln’s Production Monitoring™ process limits and define alarm and fault conditions from the robot’s touch screen pendant display.