Vertical Machining Centers

Filter by Process Zone:

VMCs Offer Jig Milling Accuracy with Machining Center Productivity

Mitsui Seiki’s “J” series offers a positioning accuracy and repeatability of +/- 1µm. Combining machining center technology with jig borer precision in one machine, the “Jig” VMCs achieve precision boring, milling, drilling and tapping.

High-Precision, Reliable Parts Processing for Tool Mold and Die Makers

GF Machining Solutions’ MILL P 500 vertical milling machine maintains positioning accuracy over extended machining times. Its Step-Tec spindle reduces secondary manual polishing – and it comes standard.

Economical Automation Solution for High-Mix, Medium-Volume Jobs

With the updated JobShop Cell PRO, Methods Machine Tools offers manufacturers a multiaxis simultaneous vertical machining center with multiple end-of-arm and infeed/outfeed options. The efficiency-enhancing cell can be immediately shipped.

5-Axis Machines Cut Diverse and Complex Shapes In One Setup

Automation options for DVF Series simultaneous 5-axis vertical machining centers from Doosan Machine Tools America save time and money by enabling shops to run production parts overnight and quickly switch over to prototype parts.

Fast, Powerful 5-Axis VMC Simplifies Program Simulations

The VARIAXIS i-800 NEO from Mazak features optional proprietary technology that optimizes processing and facilitates more accurate configuration of machine programs. Easy automation helps less experienced operators quickly build confidence to run complex parts.

Small-Footprint Vertical Machining Centers (VMCs) for Small Part Production

An economical option for small shops that need a second machine or additional spindle, all three models of Palmgren’s vertical machining centers (VMCs) have a 10-tool magazine with automatic changer and user-friendly portable handwheel.

5-Axis Vertical Machining Center (VMC) Provides Large Work Envelope Relative to Footprint

Engineered for tight-tolerance work for the mold and die, aerospace, and energy industries, Mitsui Seiki’s compact Vertex 100 provides a large workpiece capacity so operators can process a wider range of parts.

Smaller-Footprint, Easier-to-Use Vertical Machining Center (VMC)

Mazak’s VC-Ez 20 is the first of three vertical machining centers (VMCs) that offer much the same functionality and performance as previous models, but in a more compact and more affordable package.

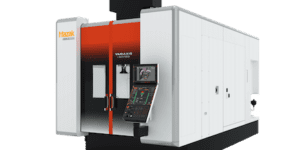

High-Speed, Large-Capacity 5-Axis Vertical Machining Center (VMC)

Thanks to a 75% increase in work envelope and high traverse rates, Matsuura USA’s MAM72-52V processes larger-diameter and heavier workpieces than its predecessor. Integrated tower pallet enables lights-out production.

How to Easily Automate Vertical Machining Center (VMC) Tending

With Quick and Simple Startup of Robotization (QSSR), Fanuc simplifies the process of connecting and programming a Fanuc robot or cobot. The all-in-one package enables operators to program the robot using the machine’s CNC.

Twin Spindles Machine Large Components With Great Precision

Available in 4- and 5-axis versions, Chiron’s dual-spindle DZ 22 has a fast spindle for machining aluminum and aluminum alloy workpieces and a strong spindle for machining hard materials and large tools.

High-Precision VMC for High-End Die and Mold Machining

Methods Machine Tools has introduced the OKK VB53a vertical machining center to the North American market, giving operators 50% more accessibility than conventional machines. They’re designed for less vibration to improve final surface finishes.