Tube & Pipe Fabrication

Filter by Process Zone:

Unison Ups Product Support Scope, Accessibility with ‘UltimateCare’

The rebranded service program facilitates selection of the right maintenance solutions, and also offers additional services such as CAD modeling, component prototyping and process optimization. Customers can choose services ala-carte or in tailored, bundled agreements.

Specialty Purging Prevents Oxidation in CMV Steel Welds

Available in many pipe sizes, HotPurge from Huntingdon Fusion Techniques HFT is an inflatable, specialty system designed to address the inherent challenges of keeping mechanical properties intact. Through continuous purging, it can maintain oxygen levels below 100 ppm.

Bending Under Pressure – To Process Enormous Tubes

Schwarze-Robitec’s CNC 60 DB Twin booster bending machine steps up to the uncompromising specifications of a major Russian boiler manufacturer. Boilers need maximum surface area to ensure highest heat transfer – the machine handles the required narrow bending and tight tolerances.

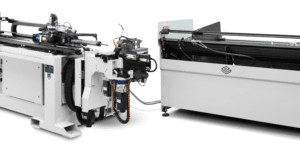

The Ultimate CNC Tube Bending for Subcontractors

Unison’s 130-mm diameter tube bender is a robust, multiradius and multistack machine with the benefit of additional component length to give buyers an edge in the subcontractor marketplace. Users are able to achieve right-first-time manufacturing for repeat subcontract work.

Updated Software Simulates and Automatically Corrects Bending Sequence

Available in two versions with varying levels of functionality, transfluid’s Windows-based t project software links geometry and material data to achieve precise bending results.

End Formers for Aerospace, Tank, and HVAC Components

Two models – the 2.5 and 4.0 – from Kaast Machine Tools ensure consistently accurate strength-promoting beads in materials up to 0.15-inch (4mm) thick. Available with mechanically (ZSM) or hydraulically (ZSH) driven upper rolls.

Track and Control Stamping Operations in Real Time From Wherever You Are

IRMCO Advanced Metalforming Lubricant Technologies’ iNSIGHT enables metal stampers to track the rate of chemical consumption by part and process and compare the data to tool life to pinpoint the actual cost per part for each process in a facility.

Two Electric Upcut Tube Saws

Two standard models – the eRB80 TS and eRB150 TS – electric upcut tube saws from Innovative Engineered Solutions (iES) cut diameters up to 3.5 inches (90mm) and 5.9 inches (150mm), respectively.

Fully Integrated System Automates Pipe Cutting From Start to Finish

HGG Profiling Equipment’s ProCutter900 RB increases throughput by continuously feeding, cutting and profiling, and moving pipe out. The small-footprint machine’s accuracy dramatically reduces post-cutting grinding, fitting and welding time.

Automated Centerless Tube Grinder

An automated version of Glebar’s TF-9BHD infeed/thrufeed centerless grinder, the TF-9D features the widest work wheel on the market. Customizable interface designed for automation and 8-5/8-inch-wide work wheel combine to increase throughput.

Autonomous Tube/Wire Bender Enables Lights-Out Production

Featuring a compact layout, integrated loading/unloading capability, and easy-to-use programming software, BLM Group’s Smart Bender enables an operator to go from design to part in one click and walk away.

Electric Rolling Device on Tube End Forming Machine

The addition of a CNC electric rolling device on BLM Group’s E-Form machine offers repeatability in part production. With punches reaching up to 10 tons of force, E-FORM molds tubes of various materials up to 30 mm in diameter.