Tube & Pipe Fabrication

Filter by Process Zone:

Increase Your Productivity with Highly Precise and Accurate Solutions

The most innovative and updated features to today’s metal forming and fabricating machinery, additive manufacturing equipment, software, controllers and accessories result in efficiencies — both in production and cost savings.

Wisconsin-based Manufacturer Installs Additional Laser Cutting Systems

Sharpe Products has added two new BLM GROUP LT7 4 kW laser cutting systems to help enhance and streamline production.

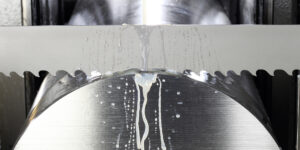

Rugged Frame and Table Ensure Vertical Toolroom Saws are Productive and Versatile

The saw can easily handle contour sawing, beveling, slicing, ripping, stack cutting and cutting off various materials from aluminum, brass to steel.

Transformative, Precise and Fast-moving Cutting Systems Expand Opportunities

No matter what your project calls for, there is an advanced cutting equipment solution to enhance and expand your metal fabrication capabilities.

Next Level Sawing

Breakthroughs in the development of robust sawing systems ensures your shop will exceed your customers’ most challenging and unique demands.

Next Level Finishing

Aggressively (but safely) and rapidly remove material and achieve precise cuts thanks to breakthroughs in surface finishing products. Electronic dosing systems ensure meticulous paint applications.

Fast Automated Bending Solution for Tall, Thick Parts

New TRUMPF TruBend Center 7020 offers highest box height of any commercially available panel bending machine and reduces cycle time by up to 80% compared to manual press brakes.

Automatic Dual Column Saws Provide Many Advantages That Increase Efficiency

Automatic dual column band saws from Cosen Saws are designed to meet the demands of modern manufacturing, service centers, and fabrication industries.

Clean Tube Technology, also Known as a “Spoon,” Option for Lasertube Machines

This option, which is available for BLM Group’s lasertubes 8” and below, helps produce a clean and dross-free internal finish.

Lasertube Machine Features new Thread Insertion Unit

A patent-pending technology exclusive to BLM GROUP, the unit simplifies the processing time required for mating an insert with a tubular component.

Automated Material Storage and Retrieval Solutions for Tube Lasers

Automation improves workplace safety and productivity by reducing downtime caused by moving raw material between jobs or restocking unused materials.

New Software Program Ensures Flexible Tube Cutting, Design and Reduced Scrap

Lantek Systems introduces Flex3d Tubes, available within the Lantek Manager and Integra software, which seamlessly integrates with tubular geometry tools such as SAT and IGES.