Tube & Pipe Fabrication

Filter by Process Zone:

TRUMPF Names New Product Managers

Adi Buerkler is product manager of TruLaser Tube, and Masoud Harooni has been named product manager of TruLaser Weld.

FANUC Awards Wauseon Machine and Manufacturing

The company has received the Sales Leadership Award and the Excellence in Intelligent Robotics Award.

Aircraft Parts Supplier Uses All-Electric CNC Tube Bending to Increase Capacity

Globe Engineering installs a new Unison machine to bend a range of aluminium, stainless steel and titanium tubes measuring up to 1.25 in diameter.

BLM Group Hires New Regional Sales Managers

Misgana Mulat, Brian Borchardt, and Manny Ortiz will help grow their laser tube and flat sheet cutting and tube bending business in the U.S. and Canada.

AK Tube Receives Safety Award

They win the 2018 Rusty Demeules Award for Safety Excellence from FMA and CNA.

JR Automation Acquires Setpoint Companies

This deal expands their footprint in intelligent automated manufacturing and distribution technology systems.

Pemamek Partners with HGG

They intend to streamline and integrate precision cutting processes with high quality welding operations to dramatically benefit customers of both companies.

Southwire Invests $9 Million Into Workforce Following Tax Reform

U.S. employees will receive bonuses and those outside of the U.S. will receive an equivalent supplement.

Bystronic Acquires TTM Laser

This expands their laser cutting portfolio into applications for tubes with diameters between 1/2 in to 32 in, and for profiles.

CRC-Evans Appoints New President

Kevin Allen is now the president of Onshore West.

Versatile, Customizable Crimping Machines

For hydraulic flexible hose connections, pipe connections, fittings, rod crimping, sockets and more, R1L-450ED/8 and R1F-4000ED/B crimping machines from Rolleri use crimp forces up to 440.9 tons and customizable options to tackle any job ranging from 7 mm to 190 mm.

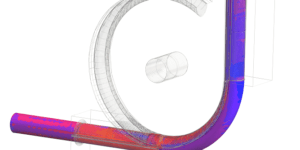

Simulation of Tube Embossing and Bending for Roll Formers

Roll forming procedures, pre- and post-processing steps can be optimally calculated to improve the forming process as a whole using COPRA FEA RF software from data M, which visualizes and verifies the production process within a virtual environment to prevent deviations during production.