Tooling & Workholding

Filter by Process Zone:

Disc Milling Inserts and Cutter Bodies for Reliability and High Performance

The 335.14 small-diameter exchangeable head system, 335.16 cutter for T-slot operations and cassette versions of the 335.25 cutter that incorporate round inserts from Seco Tools meet a wide range of customer demands for reliability and high performance machining operations.

Carbide and High-Speed Steel Tool Enhancement

Drag finishers from Bel Air can extend tool life by as much as 300 percent as an all-in-one system for cutting tool edge preparation and polishing needs.

PCD Milling Cutter for Efficient Machining of Aluminum

The Monoblock PCD Milling Cutter from Lach Diamond uses Cool Injection-Plus for cooling directly via the PCD cutting insert to achieve perfect surface quality and part accuracy, with reduced cycle times of 50 percent and more.

Eliminate Individual Torque Wrenches for Tool Assembly

A built-in torque meter in the TORCO-BLOCK tool assembly assistant from REGO-FIX eliminates the need for an individual torque wrench for every toolholder, as well as the detrimental results of excessive runout that results from over torquing.

Through-Coolant System for Radial Grooving Applications

The SE grooving and part-off system from ARNO optimizes turning, grooving, parting-off and copy turning operations.

Soft Top Jaws with Hard-to-Find Pitches for Consistent Part Clamping

Dillon can manufacture virtually any serration, including 2 mm x 60 deg and 2.5 mm x 60 deg serrations for hard-to-find top jaws, hard jaws, and full grip jaws that fit the corresponding chuck master jaws of the same hard-to-locate pitch.

Self-Tuning Mass Damper Improves Machined Part Quality, Increases Productivity, Saves Energy

Using the STMD tool holder from MAQ, parts manufacturers, machine tool builders and cutting tool manufacturers can reduce cycle time and cost of ownership by 30 percent, decrease tooling costs by 5-10 percent, cut energy consumption by 2-3 percent and curtail scrap output by 1-2 percent.

Harvey Performance Acquires Micro 100

This deal expands their footprint in milling and turning tool applications, particularly internal boring, grooving, and threading tools.

Zero Point Clamping Reduces Set-Up Times Up to 90 percent

The SMW Autoblok APS zero point clamping system from Huron Machine Products significantly reduces downtime costs and provides more versatility for turning, milling, measuring or grinding operations.

How Zero Point Clamping Increases Machine Tool Spindle Utilization

Ideal for machining individual parts and small batches, these systems drastically shorten idle time by precisely connecting workpieces, vices, pallets or devices with the machine table within seconds.

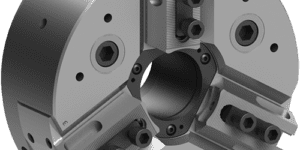

Flexible Sealed Chuck for Bar, Bar Stock and Shaft Clamping

The only sealed chuck of its kind with a large through hole, the BP Series Chuck from SMW Autoblok combines the flexibility of a standard open center power chuck with the long life and precision of a sealed chuck to maintain a constant grip force for excellent repeatability and consistency, as well as safer operation.

North American Tool Appoints New Representative

Metal Working Solutions sells their special taps, thread mills, dies and thread gages in Texas, Oklahoma, Arkansas, and Louisiana.