Tooling & Workholding

Filter by Process Zone:

Milling-Boring-Grinding of Automotive, Aerospace and Medical Parts

These indexable face milling cutters, PCD-tipped Micro Boring Bars from CITCO Tools and new bond system from Gardner Abrasives for centerless grinding increase production rates and lower cost per unit.

Finishing and Deburring Hard Materials

New tools from Brush Research Manufacturing are designed primarily for deburring, edge blending and surface finishing in hard materials like carbide, ceramic and aerospace steel alloys and can easily be integrated into automated machinery, CNC machining centers, transfer lines and robotic cells.

Schunk Adds Sales Support in Central Midwest U.S.

The OEM hires a regional sales manager to provide support to distributors of clamping technology and gripping systems in Illinois, Iowa, Missouri, and Nebraska.

BIG KAISER Targets Growth in Central U.S.

A new manager is hired to strengthen relationships with independent sales representatives and distributors in this region and grow business in high precision tooling systems.

Deformation-Free Clamping: From the Plastic Chuck Jaw to the Hybrid Chuck

When highly deformable workpieces need processing, conventional 3-jaw chucks quickly reach their limits. This primer from Schunk identifies different clamping tools and devices for deformation-free workpiece clamping and the criteria they should meet to demand efficiency and precision.

A World of Fixturing Opportunities

The use of modular fixturing for welding is a different way of doing business, but once you get started, you will wonder how you ever got along without a system. Robert Ellig of Bluco Corporation explains why.

Single Pass Complete Cavity Machining

Among the custom designed, multiple diameter carbide drills and reamers Star SU LLC are Single Pass Port Cavity Tools that allow complete cavity machining, reduce cycle times and hold industry tolerances for size and finish that are ideal for spool bore applications.

Advanced Coatings Provide Gear Cutting Edge

This ALCr-based coating from Star SU LLC is ideal for better heat resistance in high temperatures and better wear resistance for tough cutting applications with new and re-sharpened tools.

Get It Right the First Time, Every Time

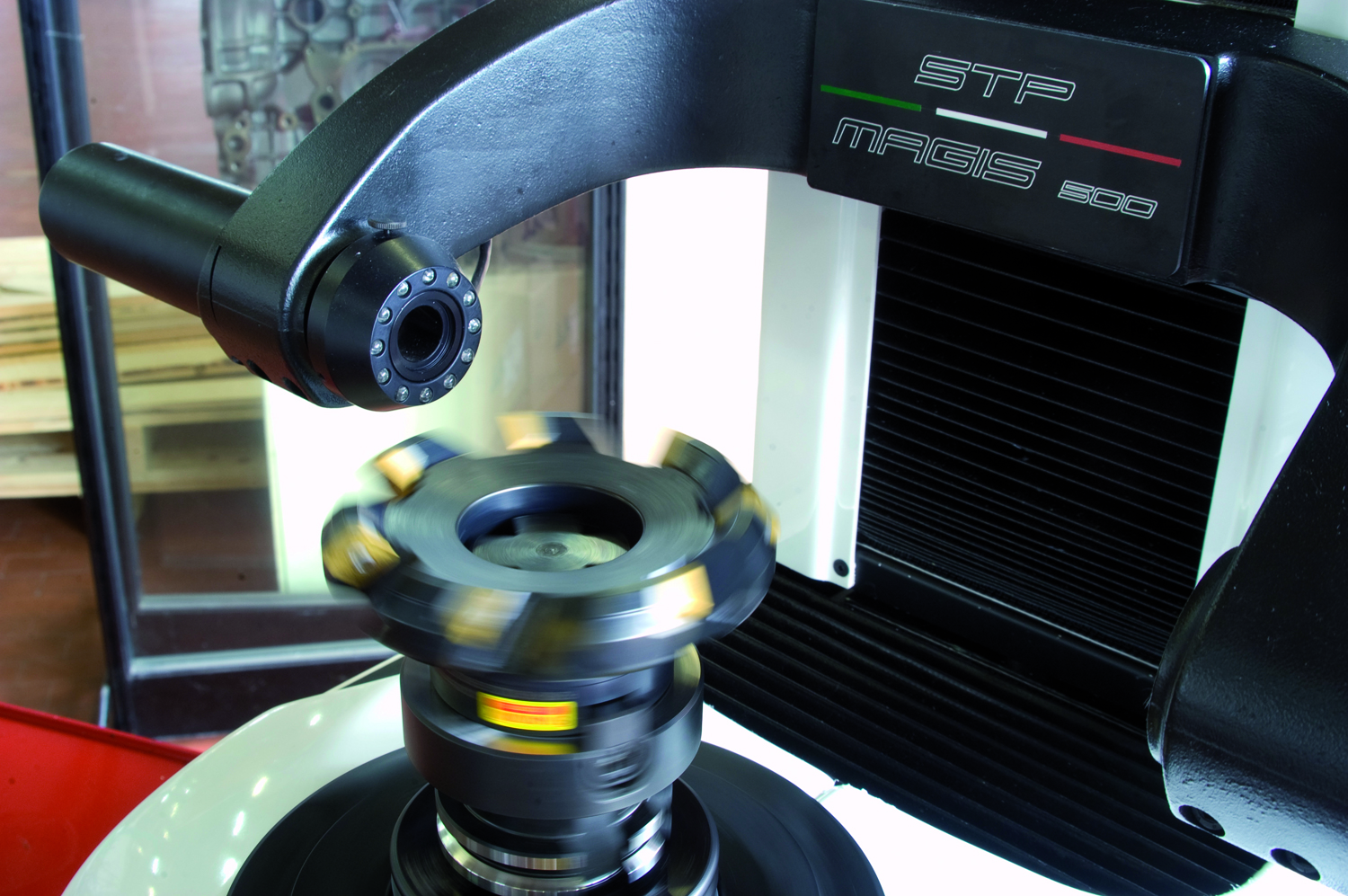

CNC machine tool efficiency is all about managing the components that must come together in proper alignment: the machine spindle, toolholder assembly and workspace.

Completing a Bucket List in Hydro Impeller Machining

By strategically moving to CNC automation and advanced tooling from Ingersoll Cutting Tools, this complex machining job at Canyon Hydro is now completed much faster and with much less operator attention as cycle times dropped by 50 percent, labor costs are virtually nil and tool life is reliable enough to run a lights out operation.

Kennametal Shlomi Plant Receives Israel’s National Quality Award

This prize is Israel’s equivalent to the Malcolm Baldridge National Quality Award in the United States.

American Punch Company Announces Same Day Deliveries

This supplier of punches, dies and shear blades to the steel fabrication industry now ships same day on all stock oblong and square tooling, regardless of customer required keyways. Also adds sizes of oblong and square punches and dies to stock tooling inventory.