Tooling & Workholding

Filter by Process Zone:

WIDIA Sponsors King of the Hammers

Extreme Challenges. Extreme Results. This event’s first sponsor outside of the racing industry brought powerful tooling support to extreme desert racing’s premier event.

Eastwood is New Distributor of Fairmount Tools

This economical line of hammer and dolly sets for metal shaping has been used by skilled craftsmen, auto body professionals and DIY hobbyists for more than 100 years.

Rex-Cut Abrasives Launches New Website

The website features easy-to-navigate technical information, videos, news, a blog, handy distributor locator, and a downloadable catalog of points, wheels, and discs for blending and polishing stainless, mild steel, aluminum, and exotics.

Wilson Tool Launches Spanish-Language Website

The new website for Spanish-speaking customers offers easy navigation to engaging, meaningful content on tooling solutions and services available locally.

Pull Out Protection: How to Increase Productivity During Roughing

These solid carbide end mills from ATI Stellram use a patented pull out protection system from Haimer and are designed specifically to meet the demands of heavy-duty cutting in aerospace and energy applications.

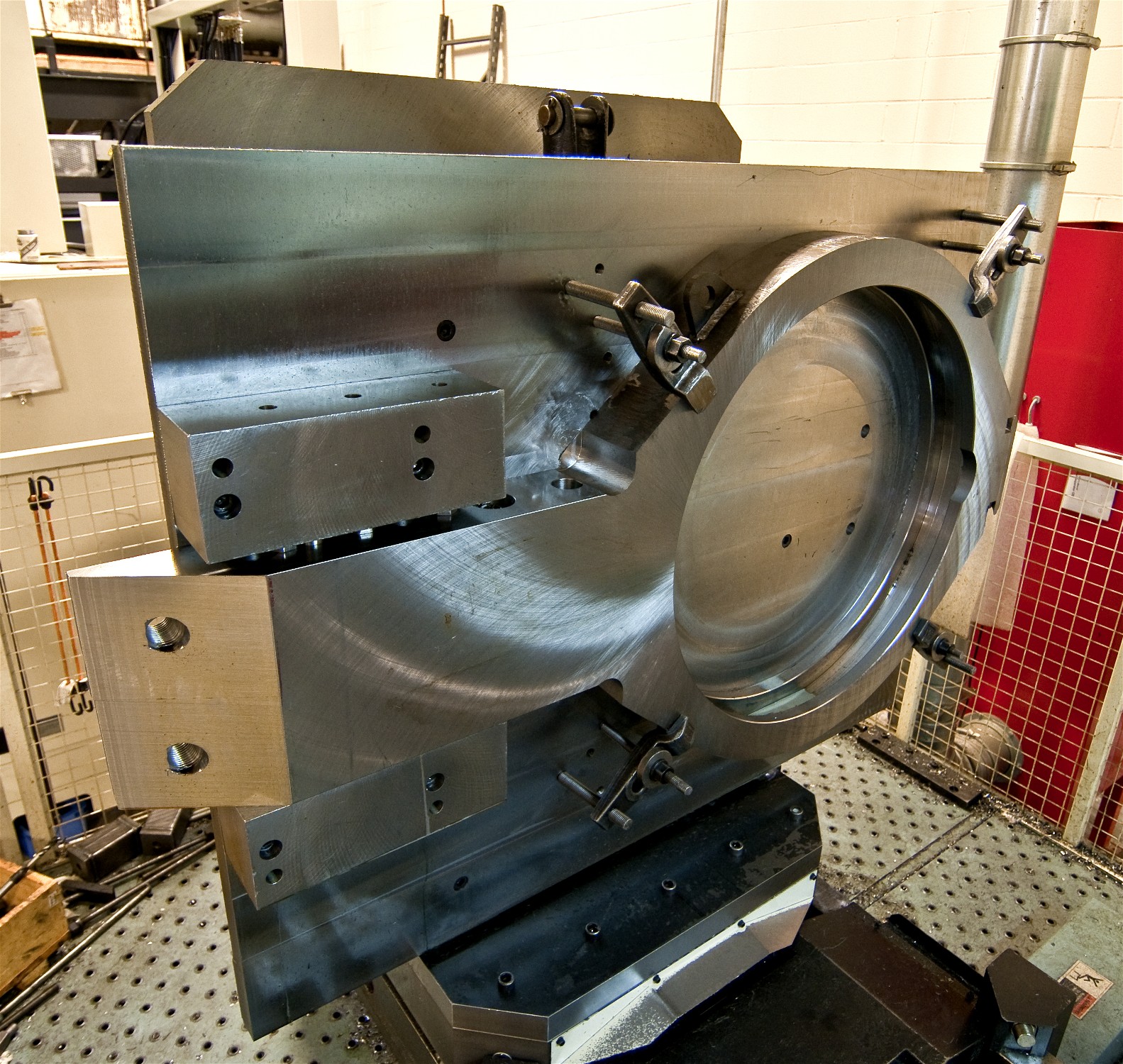

Large Holes, Larger Savings

Big holes don’t mean big bottlenecks anymore, even though some shops still don’t believe a hole can be milled right through solid steel. But R&R Machine proves it by producing big holes faster than twist drilling and with much better tolerances than flame or plasma cutting by using Ingersoll Cutting Tools.

ZOLLER Announces Workshop Series

A total of 72 workshops are planned throughout the year and will focus on optimizing production processes by introducing a transparent tool inventory management with a centralized tool data base, reducing setup times, decreasing tool costs, economical manufacturing of even small batch sizes and maintaining an overall high process security.

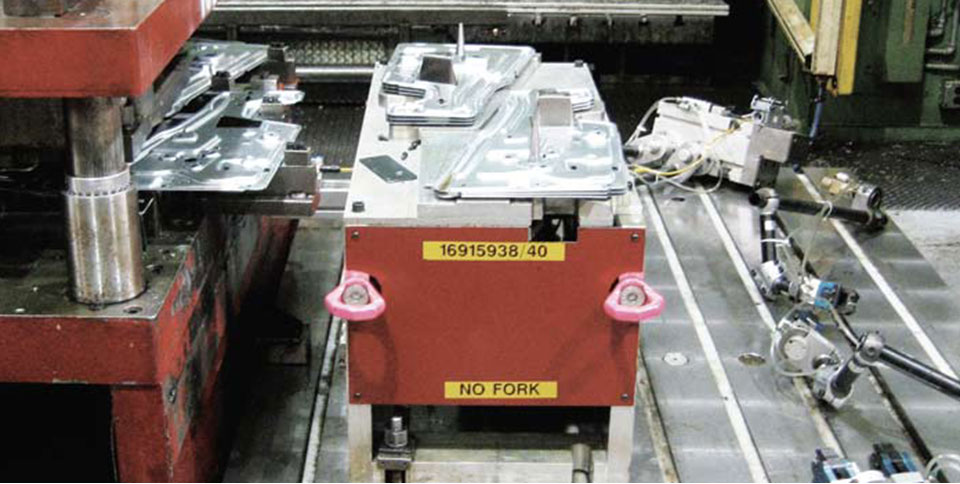

Fitting Die Maintenance Into Press Operations

When a die for a production part needs maintenance, finding the least-cost fix in the shortest time is critical. Here are some ways that tooling engineers can achieve time savings of over 80 percent and avoid costly die rework by using next generation root cause software to simulate the iteration process.

How to Use High Feed Milling on High Strength Steel

When Ace Precision Industries moved their conventional tooling and methods to a new HMC, the process worked but they could not optimize their new machine tool capabilities. By switching over to high feed milling, their machining costs dropped like never before.

Mate Precision Appoints India Sales Manager

Amit Pande is the new sales manager for India, responsible for customer relationships in India.

Hexagon Acquires New River Kinematics

This acquisition expands Hexagon’s presence in the field of measurement automation and in large-scale manufacturing processes where larger CAD models and more complex data present additional accuracy and productivity challenges.

Seco Hosts Event for “Making Manufacturing a Priority”

The inaugural manufacturing-exclusive event drew over 100 attendees, including numerous representatives from leading manufacturing companies and industry experts from consulting firms and manufacturing associations.