Tooling & Workholding

Filter by Process Zone:

2014 Tooling & Workholding Outlook: Race to the Future

Once seemingly insignificant peripherals are becoming the important difference in competing on a large scale as smart hybrid machines marry technologies once found on very different types of tools. Milton Guerry of Schunk examines how this race to the future stimulates concentration on machine accessories to match the machine technology and create a wide range of ‘add on investments’ from automation, to advanced tooling to quick change workholding.

2014 Tooling & Workholding Outlook: Reduced Process Variability

Jack Burley of BIG Kaiser explains why tooling strategies should focus on ways to reduce downtime during production due to process variables, such as time to compensate for insert wear on a boring bar or changing a perishable tool such as a drill. Offline tool presetting and zero point clamping systems are a natural part of the methodoogy for keeping spindles rotating and machine tables moving as much as possible.

2014 Tooling & Workholding Outlook: Fit for Purpose Innovation

To remain relevant in an increasingly competitive marketplace, Chris Weiler of Weiler Corporation manufacturers and their suppliers must be more agile in their customer implementation to ensure not only the delivery of the right products and solutions at the right time, but also the technical expertise and application knowledge to choose and apply those solutions quickly and collaboratively.

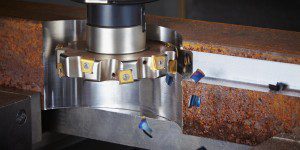

Tooling & Workholding: What’s New for 2014

Here are some of the latest tooling and workholding solutions that increase flexibility, extend tool life, reduce setup times and lower operating expenses.

Extra High Jaws Extend Life, Reduce Costs and Inventory

The extra length of the DMI Series chuck jaws from Dillon Manufacturing provides greater work piece stability, allows multiple uses of the blank, and avoids extra time and costs associated with the welding and bracing needed to lengthen a standard height top jaw.

Stainless Steel Quick-Change Pallet Work Station

The NSL VERO-S system from Schunk is designed for quick and easy implement of a quick change pallet system with a universal standard for all machines, regardless of their machine variety or table size. The NSL units can even be combined to create an even larger base plate.

Tooling Lightens the Load on Stamping Robots & Personnel to Maximize Productivity

The Accelerate Collection of lightweight tooling features end effectors from DE-STA-CO are up to 50 percent lighter than others, providing automated pressroom stamping line productivity improvements of 25 to 30 percent.

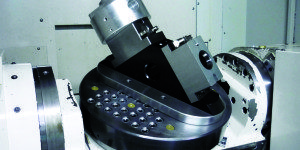

Easier Pallet Automation to Automate Horizontal Machining Centers

The first step into pallet automation is now shorter than ever with a compact FPC system from Fastems that handles pallet sizes from 400 mm to 1250 mm and workloads from 750 kg to 7500 kg on up to three machining centers.