Tooling & Workholding

Filter by Process Zone:

Shoulder Mill for Cutting Steel, Stainless Steel, Cast Iron

The PWS Shoulder Milling Cutting Series from Sumitomo is an excellent roughing tool that takes heavy depths of cut and punishment in various materials and still provides excellent tool life.

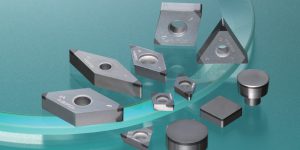

CBN Turning System for Machining of Cast Iron

The BN7000 from Sumitomo Electric Carbide provides excellent wear and thermal crack resistance in the high speed machining of grey cast iron.

Cutoff Wheel for Thin Metal Fabrication

The A 980 TZ Special cutoff wheel from KLINGSPOR is ideal for precision, burr free cutting of extremely tough to cut alloys.

Air Chuck Jaws Grip Delicate Parts Without Damage

The Dillon pin with location top jaws from Dillon Manufacturing firmly holds small and delicate parts being machined with air chucks without damaging or marring their surface.

Pipe Beveling Tools Don’t Need Cutting Oils

MILLHOG® Cutter Blades from ESCO produce clean, consistent end prep angles from 37 deg to ½ deg to 10 deg and compound bevels.

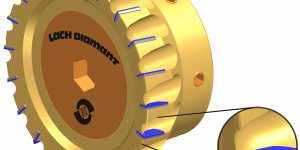

Milling Cutter Optimizes Aluminum Machining

The PCD Monoblock MB-X3 milling cutter from Lach Diamond uses a direct cooling system combination that can reduce cycle times up to 50 percent and more.

Engineered Finishing and Polishing Solutions

The Osborn lab operates as a test and competency center for engineers to develop state-of-the-art solutions to difficult polishing and finishing problems.

Parting Off System for Deep Grooves, Long Overhangs

CoroCut QD from Sandvik Coromant ensures predictable and consistent tool life for reproducible parts in high volume bar feeding applications.

Revolutionary Compact Pneumatic Lever Clamp for Tight Spaces

With space in short supply on complex welding and assembly fixtures, the 8700 series pneumatic lever clamp from DE-STA-CO provides superior holding power for any type of tooling.

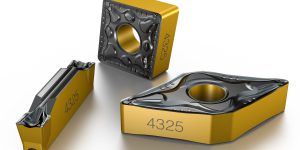

Steel Turning Grades for Machining Transmissions

Grades GC4315 and GC4325 with Inveio from Sandvik Coromant are ideal for soft stage turning that comes before case hardening.

The Whole Picture in Holemaking

Today’s holemaking techniques need to be more efficient than ever to meet greater demands and closer tolerances. Ultimately, the tool — and its application — matter. For optimal success, it’s time to see the whole picture.

Students Entering Manufacturing Thank Their Corporate Partners

On Manufacturing Day, SkillsUSA recognized industry partners that help students succeed as entry-level manufacturing employees.