Toolholders & Adapters

Filter by Process Zone:

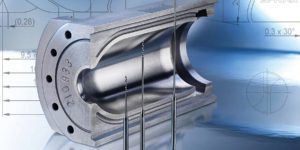

Safe Heavy Duty Machining of Difficult Materials

The importance of the tool holder is still understated in roughing and heavy duty machining, where metal removal rates are absolutely crucial for productivity. But now, using special shrink fit chucks with drive pins and spiral grooves in the tool shank, it is possible to perform high-feed full slotting up to 2xD (50 mm) or more in difficult to machine materials.

Velocity/Briney Joins Partners in THINC

They now supply the Velocity SMART Tool toolholding system exclusively for Okuma CNC machining centers.

Medical Machining: Tooling

Take a closer look at some of the newest tooling that can help contract manufacturers meet the machining, micro machining, and laser processing demands for smaller and more complex surgical implants, orthotic devices and medical instruments that are being made from newer materials – and still hold their costs down.

Thread Whirl Toolholder for Complex Thread Production of Medical Bone Screws

An inexpensive alternative to dedicated thread whirling machines, this toolholder from EXSYS Tool is ideal for processing micro-components and machining high-precision OD threads in challenging materials with long, slender thread profiles.

High Speed Air Power Spindle for Micro-Machining Medical Parts

Driven by air supplied through a stop block or through the machine spindle, the RBX12 Air Power Spindle from BIG KAISER achieves variable rotational speed of 100,000 rpm to 120,000 rpm so that normal machine tools can be upgraded cost effectively to perform micro-machining.

What You Need to Know Right Now to Improve High-Volume Micro Manufacturing

Opportunities abound for shops to cash in on the ever-growing micro machining market, but the differences between different types of micro tools vary from those found in standard tooling. Here are some insights into the extra care and know-how needed to achieve success and build a successful reputation as a reliable supplier of micro machined parts.

IMTS 2016: Tooling & Workholding Systems

Good tooling not only gives new capability to older equipment, it is a key to productivity and cost efficiency on all machine tools. Maximize the investment in your machinery and equipment with the latest tooling technology and state-of-the-art workholding systems that allow minimum setup and machining time.

Rapid Mechatronic Gripper for Small Part Handling

The EGP electric small part gripper from SCHUNK uses a grip force of 13 N to handle parts up to 0.05 kg.

High Speed Spindles for Milling, Cutting and Grinding

Powerful high speed Micro Line spindles from IBAG fit Swiss turning machines in spindle sizes from 16 mm to 33 mm diameter, speeds to 120,000 rpm and power to 390 watts.

Take Care of Tool Holders, Prevent Cycle Disruption

There are three particularly sensitive areas of the tool holder assembly that can experience process-affecting wear and tear and cause a cycle to change. By identifying and addressing issues early in these areas, you can prevent small tool holding imperfections from turning into bigger problems.

Haimer and Mapal Reach Licensing Agreement

Starting in October, Mapal will offer selected cutting tools for high-performance machining with the Safe-Lock shank from Haimer.

Haimer Introduces Partnership Program to Distributors

The Haimer Competence Center Partner program provides premier benefits to a select group of the company’s most technical distributors.