Toolholders & Adapters

Filter by Process Zone:

Modular Clamping System Reduces Setup Time, Increases Machine Utilization

The FCS Modular Clamping System (Breyl) from SST uses virtual design during the CAD/CAM stage of part production to project a grid on the workpiece and calculate the best way to attach the part for machining and chip evacuation.

BIG KAISER and Team Penske Form Technical Alliance

Team Penske will now use BIG KAISER technology for machining parts for their Ford Fusions and Mustangs used in NASCAR racing.

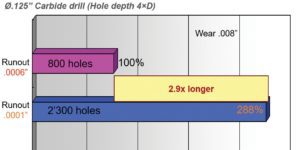

Tools, Holders and Runout: Uncover the Hidden Savings

Runout can be fickle, but finding a solution for it can pay significant dividends. Here are some insights into how much a little wobble can really increase your costs.

Advanced Toolholders and Workholding

New extended reach and hydraulic toolholders, CNC accessories and magnetic workholding systems from Techniks can reduce setup time and change-over time by 50 percent and handle load capacities up to 6,600 lb.

Machining Heat Resistant Super Alloys at High Speeds

Cutting speeds soar on tough-to-machine materials with these new tools from NTK Cutting Tools.

Haimer Acquires Microset in Stronger Partnership with DMG MORI

All DMG MORI facilities worldwide will now be exclusively equipped with Haimer tool presetting, balancing and shrinking, and shrink fit holders.

A Review of Vibration and Affordable Ways to Prevent It

While the latest machine tool technology may go a long way towards eliminating vibration and chatter, adding a new one may not be realistic. Luckily, there are less disruptive options that can make positive impacts on vibration without breaking the bank.

Make the Most of a Tool’s Entire ‘Life’

Successful shops always look for ways to differentiate and innovate for competitive advantage. Cashing in on the entirety of a tool’s life with an advanced tool management system is perhaps the most effective way to do that right now.

Haimer Adds New Canadian Applications Sales Specialist

Matt Seessle provides sales and technical support throughout Canada.

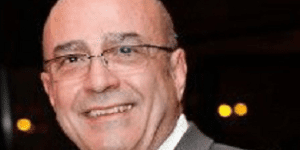

BIG KAISER Receives NTMA Award

Chris Kaiser, the president and CEO of the company, is recognized with the 2016 NTMA Distinguished Service Award.

A Peak Behind the Curtain

The value of a major trade show is that exhibitors give you so many opportunities to gain a leg up on your competition. Here are some insights to consider so that the next event you attend will speak directly to your bottom line.

Machining Heat-Resistant Super Alloys? Hold On Tight

The chances of a tool slipping or pulling out in its holder during work is increasing as more shops opt for heat-resistant super alloys – stainless steel, Inconel, titanium and others – over aluminum. These metals are lightweight, strong and corrosive-resistant, but they are very difficult to machine. Here are some insights into tool wear in these applications that can help you select the proper holder for your work.