Surface Roughness/Finish

Filter by Process Zone:

Versatile and Virtually Seamless Dual-Measurement System

All Mitutoyo America FormTracer Avant models can be retrofitted with detectors that convert a contour measuring unit or surface roughness tester to a high-precision system that measures both attributes without closing down the software or switching off the controller.

Double-Duty Measuring of Big Components

Combining dimensional metrology and surface roughness measurement, the InfiniteFocus G5 from Bruker Alicona provides high repeatability and vertical resolution of up to 10 nanometers. An interface equips the system for fully automatic measurement during production.

Affordably Priced Handheld XRF Analyzer

The Vanta Element from Olympus Scientific Solutions Americas provides the same fast material- and alloy-grade identification as the line’s other models in a rugged, cost-effective package. The 2.9-lb X-ray fluorescence (XRF) analyzer works in temperatures ranging from 14 degrees F to 113 degrees F (-10 degrees C to 45 degrees C).

Metrology Equipment Maker Upgrades Calibrator, Introduces Higher-Resolution Digital Indicators

Mahr Inc.’s Precimar ICM 100 IP can be retrofit to automatically calibrate dial and digital indicators, test indicators, and dial comparators. Six higher-resolution options expand potential applications for MarCator 1086R-HR and 1087R-HR digital indicators.

Never-Before-Possible Roughness Measurement

A MarSurf GD roughness measuring station from Mahr Inc. can do profile and waviness evaluations in addition to surface roughness evaluations on larger parts or a series of smaller parts staged together – all on the same machine.

Measuring Small Components

The Flying Spot SurfaceMeasure 201FS laser sensor from Mitutoyo uses a point scanning method to achieve high reproducibility, best-in-class scanning accuracy and a high data acquisition rate for inspection and reverse engineering of small components.

Optical Inspection of Cylinder Bore Surfaces

The Hommel-Etamic Toposcan system from Jenoptik can automatically measure the size of porosity and blow holes, stroke reversal radius, laser pocket structures, roughness of bore walls, torn and folded metal and cross-hatch angles.

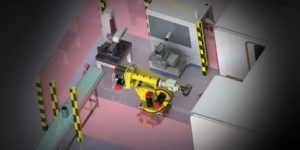

Automation and Metrology

To remain competitive, more shops are searching for ways to better utilize their quality workforce and supplement them with automation. But Ken Myers of Mitutoyo America explains that what automating metrology means to one person might not mean the same to another.

Blum-Novotest Appoints New Regional Managers

Brian Morris manages sales and service in the Southwest U.S. while Andrew Nichols manages the Midwest.

AHB Tooling & Machinery Changes Ownership

Mike Gleason and Jon Hays purchase this metalworking distributor from Kevin Hess.

Faster Inspections of Welds and Stress Corrosion Cracking

The MagnaFORM scanner from Olympus is a fast, reliable way to reduce the turnaround time of weld inspection and stress corrosion cracking inspections on the roughest welds and corroded surfaces, saving time and reducing inspection costs.

Fives Partners with NRC Canada

They are developing a new profilometer for faster, more accurate part inspection of composite structures used in aerospace manufacturing.