Surface Roughness/Finish

Filter by Process Zone:

Machined Metal Parts: Tips to Ease the Inspection Process

Selecting a videoscope with a suitable scope diameter along with ergonomics and durability can help inspectors stay comfortable and productive.

Achieve Zero Defects with Innovative Measurement and Inspection Solutions

Uncover hidden defects before downstream processes are impacted with the latest 3D scanners, powerful software packages and portable measurement devices.

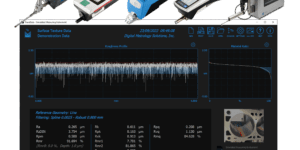

Digital Metrology Introduces TraceBoss Software for Portable Roughness Gages

One click in TraceBoss configures the gage, initiates a measurement, and presents the results and graphics full screen and in high resolution.

Huntingdon Fusion Techniques Updates PurgEye® 100

The handheld device now features a metal housing and readings are from atmospheric oxygen level (20.94%), down to 100 ppm (0.01%) of oxygen.

RFP Fringe Probe Increases 5-Axis Measurement System Flexibility

Renishaw’s multisensor REVO 5-axis measurement system provides highly accurate scanning, non-contact inspection and surface finish analysis at ultra-high speeds on one coordinate measuring machine (CMM).

Submicron Surface Roughness Measurement

The LEXT OLS5100 laser microscope from Olympus guarantees measurement accuracy that simplify experiment workflows. The software’s several smart features minimize error with push-button scanning and analysis.

Laser Measures Wide Range of Hard-to-Reach Surfaces

Optical Gauging Products’ multisensor TeleStar Plus laser measures a wide range of materials and surface textures with extremely high accuracy. Its through-the-lens (TTL) design eliminates offset between the optical and laser sensors.

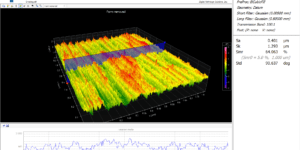

Surface Measurement for Non-Metrologists

OmniSurf3D from Digital Metrology Solutions helps users understand and communicate about surface texture without requiring a great deal of mathematical interpretation or metrology knowledge. The software provides the ability to interact with data from virtually any surface measurement instrument.

Abrasives Are Not All Created Equal

Many shops hesitate to incorporate abrasive finishing tools in CNC machines for fear of clogging coolant lines and damaging slides and bearings. However, finishing tools generate very little grit.

Versatile and Virtually Seamless Dual-Measurement System

All Mitutoyo America FormTracer Avant models can be retrofitted with detectors that convert a contour measuring unit or surface roughness tester to a high-precision system that measures both attributes without closing down the software or switching off the controller.

Double-Duty Measuring of Big Components

Combining dimensional metrology and surface roughness measurement, the InfiniteFocus G5 from Bruker Alicona provides high repeatability and vertical resolution of up to 10 nanometers. An interface equips the system for fully automatic measurement during production.

Affordably Priced Handheld XRF Analyzer

The Vanta Element from Olympus Scientific Solutions Americas provides the same fast material- and alloy-grade identification as the line’s other models in a rugged, cost-effective package. The 2.9-lb X-ray fluorescence (XRF) analyzer works in temperatures ranging from 14 degrees F to 113 degrees F (-10 degrees C to 45 degrees C).