Stick Welders

Filter by Process Zone:

Engine-Driven Welder Enables Simultaneous Welds

Lincoln Electric’s Dual Maverick 200/200X is two welders powered by one diesel engine with two outputs, allowing two or more welders to work at the same time. Output remains steady even during arc stops and starts in dual mode.

How to Reduce Weld Defects and Improve Productivity

Advanced welding technologies from Miller Electric provide great process flexibility, reduce welder training time, minimize spatter and rework and improve weld quality for manufacturing, fabrication and construction applications.

How to Improve Productivity and Performance of Field Welded Moment and Column Splice Connections

These best practices for welded moment connections and column splices in the field require an up-front investment of time and money, but considering how much you’re likely leaving on the table, it’s a small price to pay.

What You Need to Know About Weld Anatomy and Joint Geometry

Are you wasting lots of time and money on welds that are larger than they need to be, particularly on thicker materials? Or dealing with inconsistent quality or increased crack sensitivity due to welds with improper dimensions? There are many different ways to design welds that strike the best balance between weld quality and productivity.

Switching Polarity in Welding Applications

When competing for time-critical jobs, saving even a few minutes with each changeover can make a significant difference and reduce operator exposure to trip and fall hazards. Investing in technology that allows welders to easily change processes with the push of a button at the weld joint can save substantial time, increase weld quality and improve operator safety.

Lincoln Electric Promotes Senior Managers

Dan McMillin is now their vice president and corporate controller, and Bob Nelson is vice president of finance for their Americas Welding segment.

Polarity Reversing Saves Pipe Welding Time and Money on the Jobsite

Using Quick-Select technology that automatically selects correct polarity, lead outputs and weld parameters, the new XMT 350 FieldPro system with Polarity Reversing from Miller Electric eliminates the need to manually swap leads between welding processes.

Battery-Powered, Rail-Mounted Tractors for Mechanized MIG/MAG Welding

ESAB offers the Railtrac B42V rail-mounted tractor with a new weaving unit and the compact Miggytrac B501 battery-operated tractor for flexible and consistent mechanized welding of long and even not-so-long joints and seams.

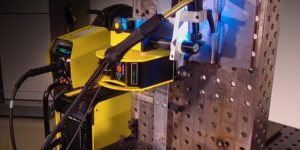

Remote Monitoring of All Open Arc Welding Processes

The rugged XVC-1000e weld camera from Xiris monitors MIG/MAG, TIG, plasma, laser or stick welding in exceptional detail from up to 100 m away.

Improve Welding Productivity, Safety and Quality on Construction Jobsites

Even hundreds of feet away from the power source, ArcReach technology with Cable Length Compensation and Adjust While Welding capabilities from Miller Electric can save up to two hours per welder per day on construction jobsites by ensuring the voltage set by welders is the same they get at the weld.

Make My Miller Machine Giveaway Launches

The contest winner will receive a Miller Electric welding machine that can be customized with a design by artist Max Grundy.

How to Tailor Pulsed TIG Welding to Thin Material and Stainless Steel Pipe

The Renegade ET 300iP DC TIG/Stick inverter from ESAB features controls for pulsed TIG welding that can improve weld puddle control, control the weld bead profile, reduce heat input and increase travel speeds on stainless steel pipe used in food, process piping and mechanical contracting applications.