Software

Filter by Process Zone:

Cloud-Based Operations Software Simplifies and Optimizes Manufacturing

Global Shop Solutions’ Cloud ERP combines maintenance-free software and speed with quick and simple, automatic cloud-based data backups. Files and data are never lost; updates and maintenance are done in-house so users always work with the most up-to-date version.

Manufacturing is the Secondary Operation for This CNC Machining Shop

San Francisco-based Plethora Corp. shaves as much time as possible from the iterative design process. After developing software that enables customers to design for the shop’s capabilities in real time, this 2017 start-up delivers prototypes and production runs within three days.

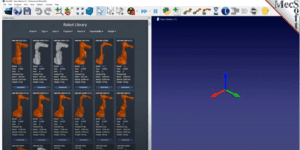

MecSoft-RoboDK Partnership Facilitates Milling with Robots

The synergistic alliance between Mecsoft and RobotDK means milling solutions can be adapted for robotic milling applications. The RobotDK simulation software supports over 500 robot arms and more than 50 different robot controllers.

Work Instruction Software Free Till Pandemic Ends

VKS is making its VKS Lite available at no charge to help companies rapidly disseminate internal knowledge. The software is beneficial for standardizing best practices as well as for training new staff.

Forging the Factory of the Future

Manufacturer signs three-year service agreement that will transition the operation from fixing one robot at a time after a failure to monitoring the performance of 30 robots individually and as a fleet.

Have We Achieved Lights-Out Electrical Discharge Machining (EDM)?

In line with Industry 4.0, the rConnect central communications platform from GF Machining Solutions is one step closer to elimination of process downtime, improved machine performance, and fully predictive manufacturing process and product quality.

Mitsubishi Electric Consolidates CNC After-Sale Services

Tailored for the company’s M8, M7, and M6 Control Series, the CNC Total Care Package combines software backup, machine tuning, and preventive maintenance to minimize downtime. The goal is to make customers’ machines as productive as they were when new.

Artificial Intelligence Powers Spindle Health Monitoring

Predictive analytics diagnose pre-failure conditions before downtime occurs. Mazak’s Spindle Health Monitoring System uses edge computing and algorithms to model a spindle’s baseline signature against which anomalies that indicate developing alignment or balance issues are readily identifiable.

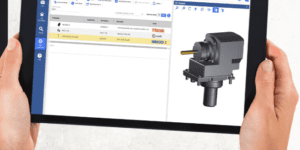

Cloud-Based Cutting Tool Configurator Saves Time and Money

MachiningCloud fast-tracks a shop’s entire workflow by providing direct access to tooling data and speed-and-feed recommendations that can be read directly into CAM and simulation programs. In addition to enabling users to quickly configure the right tool for a job, the platform provides pricing and availability.

Keep Working Remotely with Free Software Services ‘Til Year-End

To help their customers maintain production during the pandemic, ABB announces that as of March 27, they will offer key digital services at no charge. These services include ABB Ability Connected Services and RobotStudio, and the company is also providing complimentary virtual technical support.

Drills for Higher Reliability in Aerospace, Automotive, Oil & Gas Applications

Sandvik Coromant’s solid carbide drills – the CoroDrill 860 with -SM geometry, the CoroDrill 860 with -GM geometry, and the CoroDrill 863 with -O geometry – improve consistency and performance on workpieces made from challenging materials such as heat-resistant super alloys (HRSAs), titanium alloys, and composites.

Parts Distributor Becomes Profitable Job Shop After Deploying Flexible Manufacturing System

What with designing tombstone fixtures, selecting tooling, and programming the operations, the time and money required to buy and use a flexible manufacturing system (FMS) may be off-putting. But as this Massachusetts manufacturer learned, the investment brings peace of mind by providing financial stability.