Shears

Filter by Process Zone:

Faster Cycle Times and Consistent Output Empower Fab Shops

Advancements in compact and automated solutions for bending, pressing, and stamping ensure speed, repeatable accuracy and precision.

Ironworker Models and Shear Model to Come Standard with LED Lights

Scotchman Industries low profile LED lights have proven effective for brightly illuminating the workstation and workpiece.

CINCINNATI EZ BEND™: Bringing Automation to the Shop Floor Through Collaborative Robotic Technology

Transform your operation with EZ Bend, the easy and innovative way to integrate automation. Free up your press brake operators to focus on complex bends ensuring a smooth and efficient operation for even the most complex tasks.

More Ergonomic, Easy-to-Use Shear from TRUMPF

Now available in North America, a flexible, high-performance, battery-powered hand tool from TRUMPF, the TruTool S250 LiHD 18V shear, is now even more ergonomic and easy to use.

Trilogy Machinery’s Processes and People Ensure Your Success

Stocked with metal fabrication machines ranging from entry level to custom designed, and full parts and service departments, Trilogy Machinery collaborates with customers to determine the best solutions for their applications.

Increase Your Productivity with Highly Precise and Accurate Solutions

The most innovative and updated features to today’s metal forming and fabricating machinery, additive manufacturing equipment, software, controllers and accessories result in efficiencies — both in production and cost savings.

Corporate Profile: Betenbender Manufacturing Inc.

Shears & Press Brakes: Made in the USA since 1972.

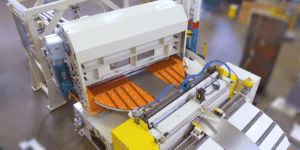

New 2500 Ton Compression Molding Press

The new press features 10-foot square heated platens maintaining 500-degree (Fahrenheit) surfaces to +/- 5 degrees, and an innovative transfer system.

The Freedom to Innovate: TRUMPF Inc. Assists Customers in Realizing Their Greatest Projects

The embodiment of TRUMPF is the ability to integrate its high-quality machine tools with its high-quality lasers to build machines that enhance their customers’ competitiveness.

Innovative, Fast and Straightforward Solutions

Press breaks, stamping presses and shears facilitate productivity increases and cost savings.

Oscillating Servo Shear Offers Smooth Repeatable Precision with Reduced Maintenance

COE Press Equipment’s (Sterling Heights, MI) Oscillating Servo Shear, as compared to hydraulic shears, is designed to significantly reduce maintenance time and costs as well as provide energy savings and noise reduction.

With Skelton Crew, Teleservice, Parts Maker Not Quitting on Customers

LVD Strippit has kept its New York plant and all four of its North American support facilities open during the pandemic to continue supplying parts and aftermarket service to essential manufacturing businesses. And when remote service isn’t enough, their techs hit the road to keep customers’ equipment running smoothly.